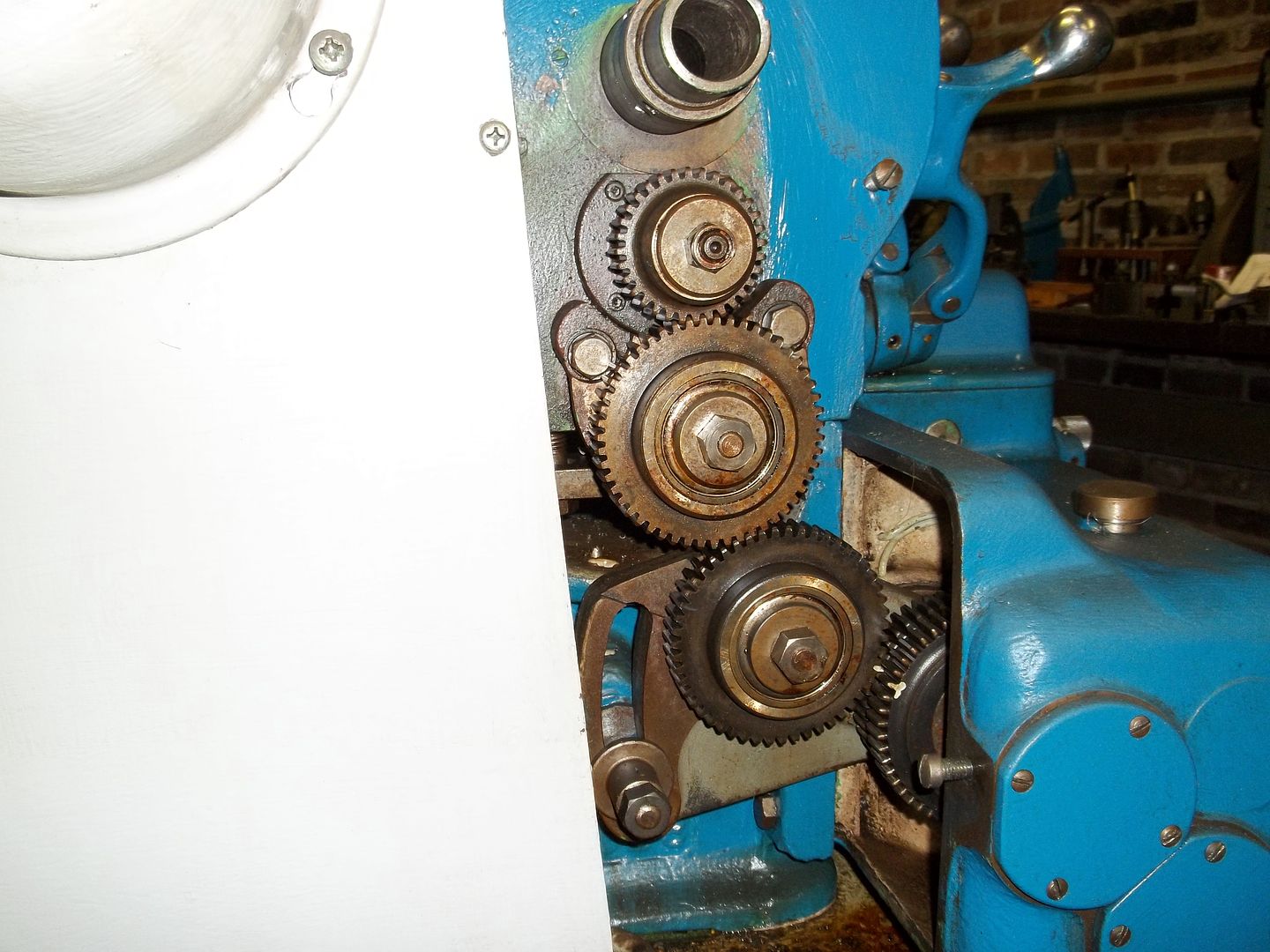

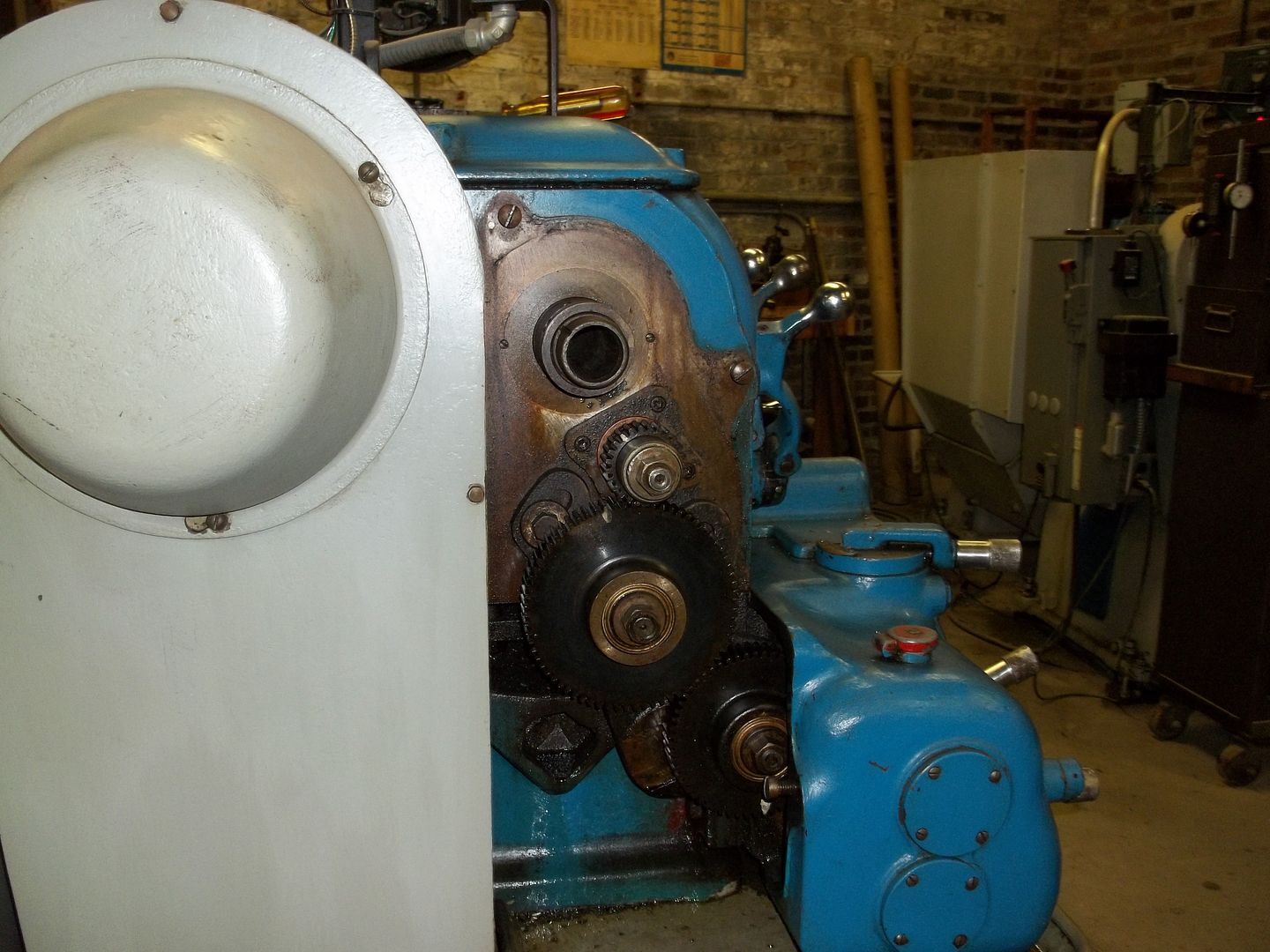

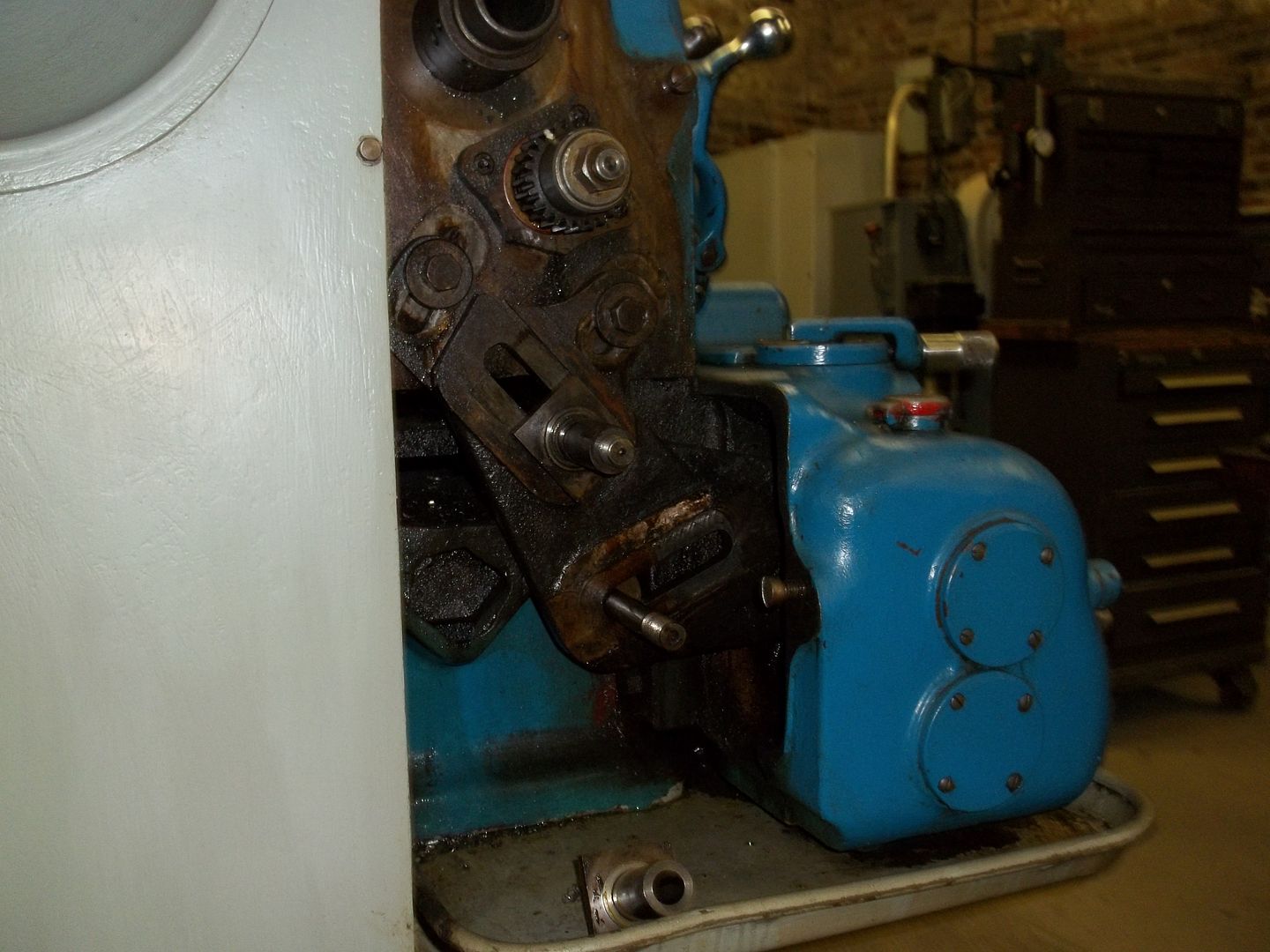

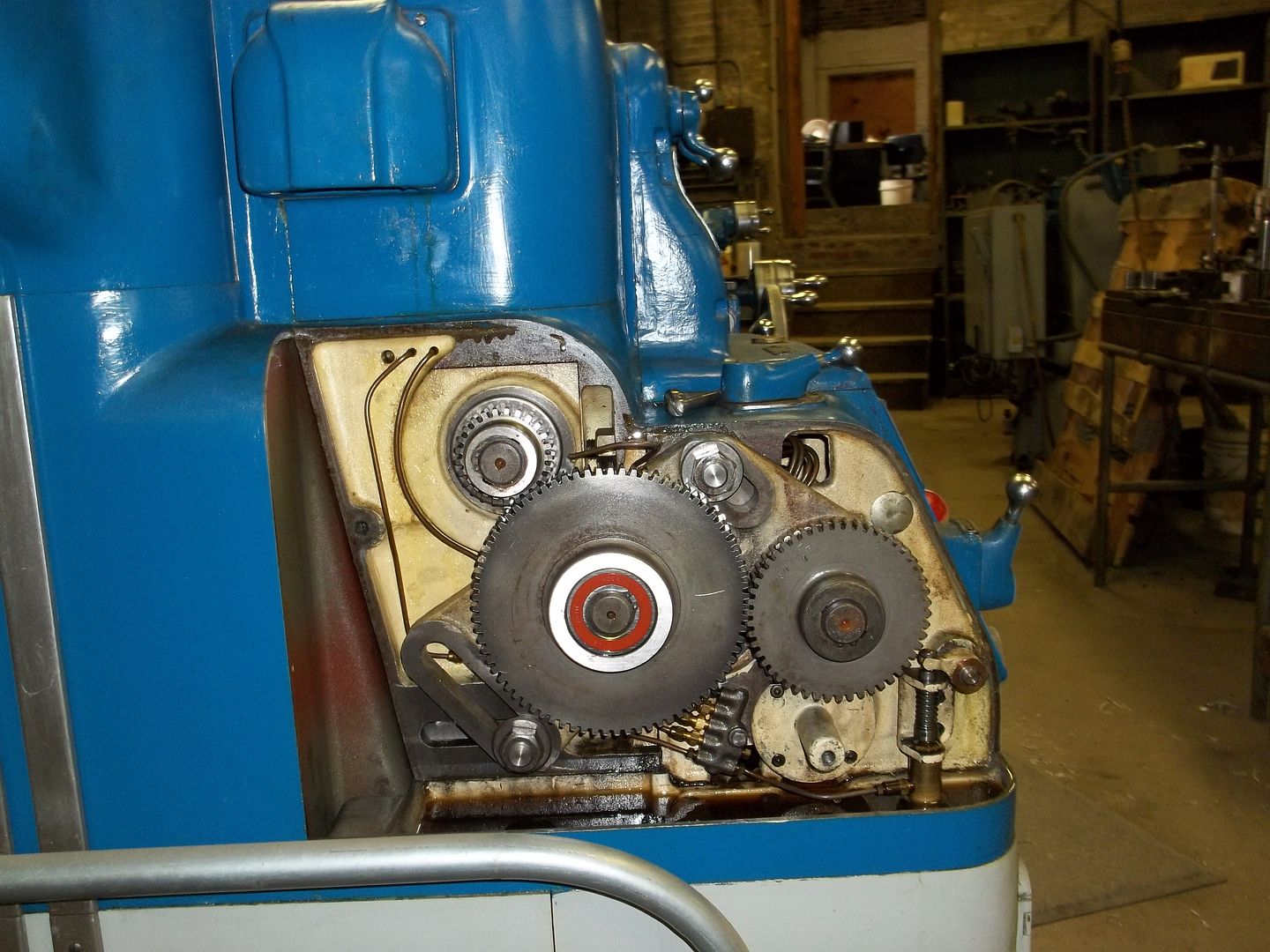

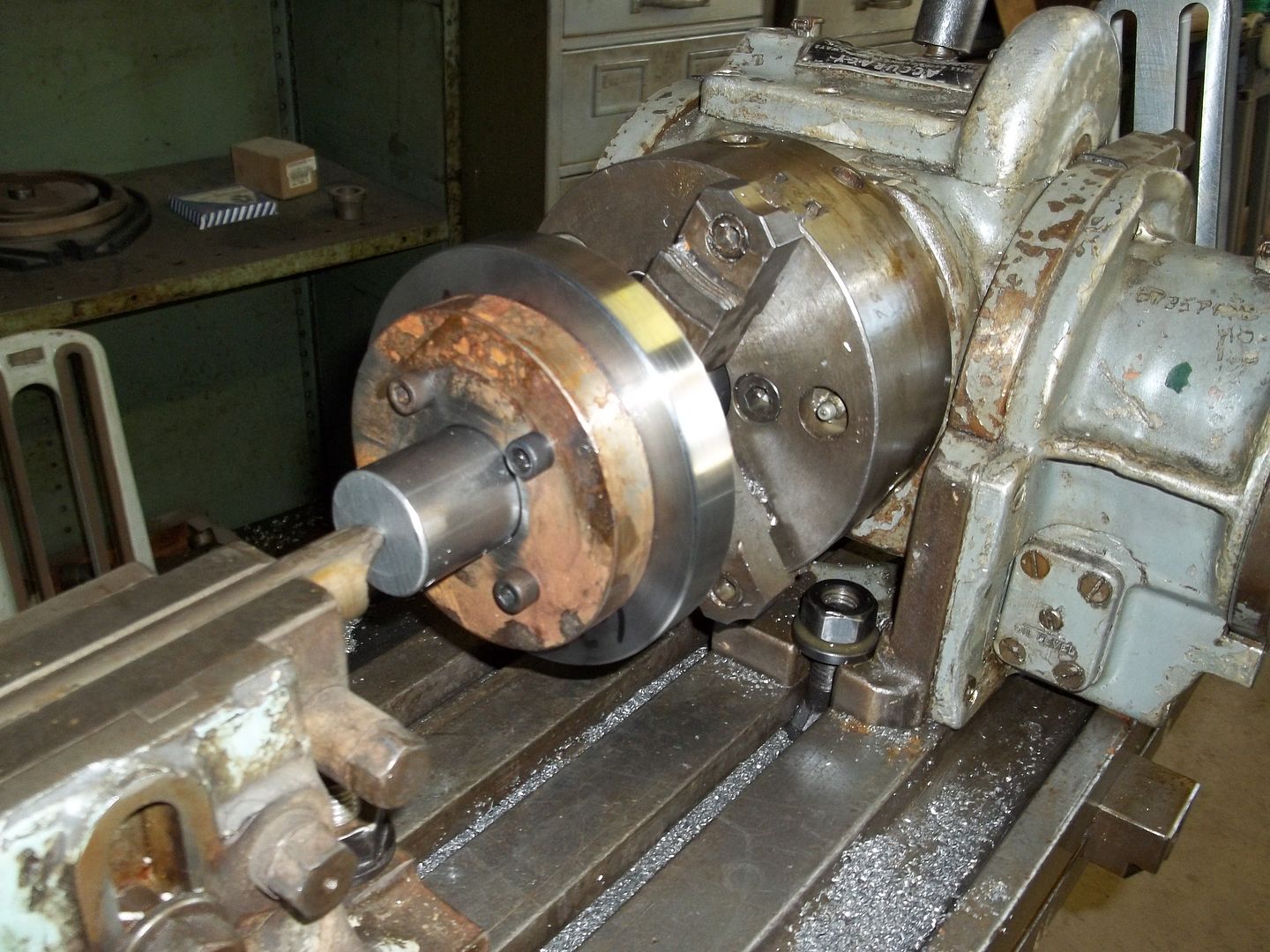

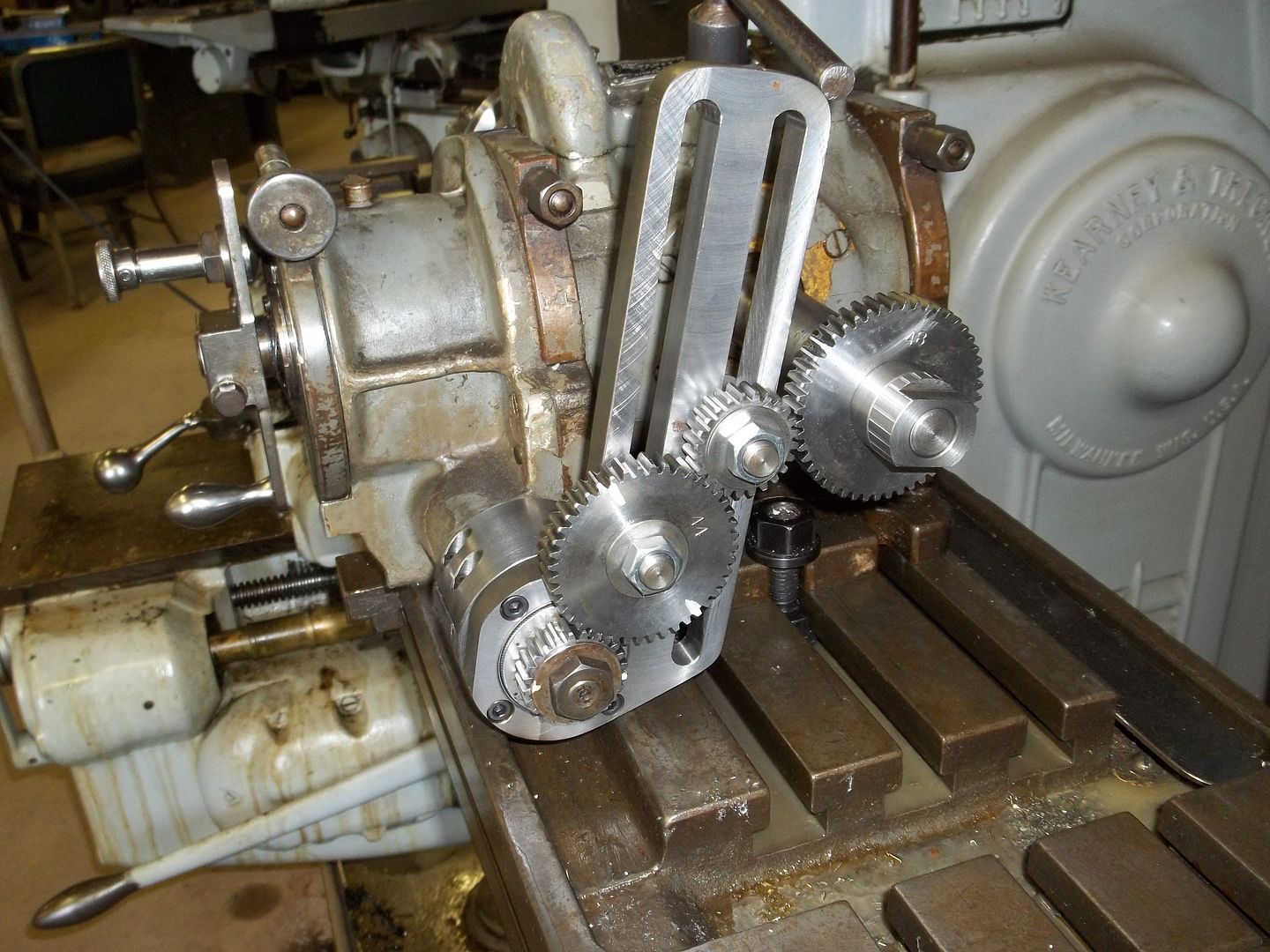

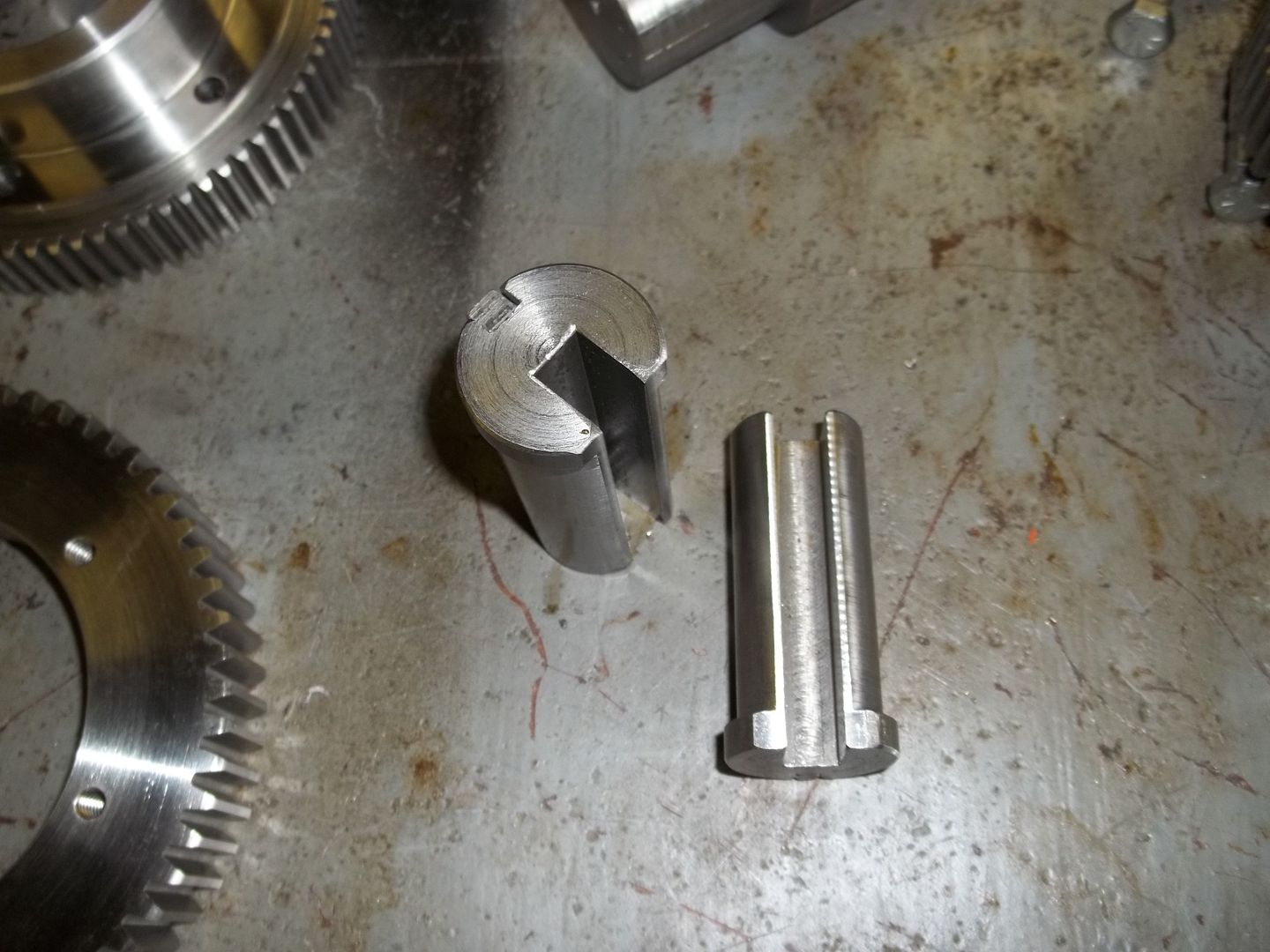

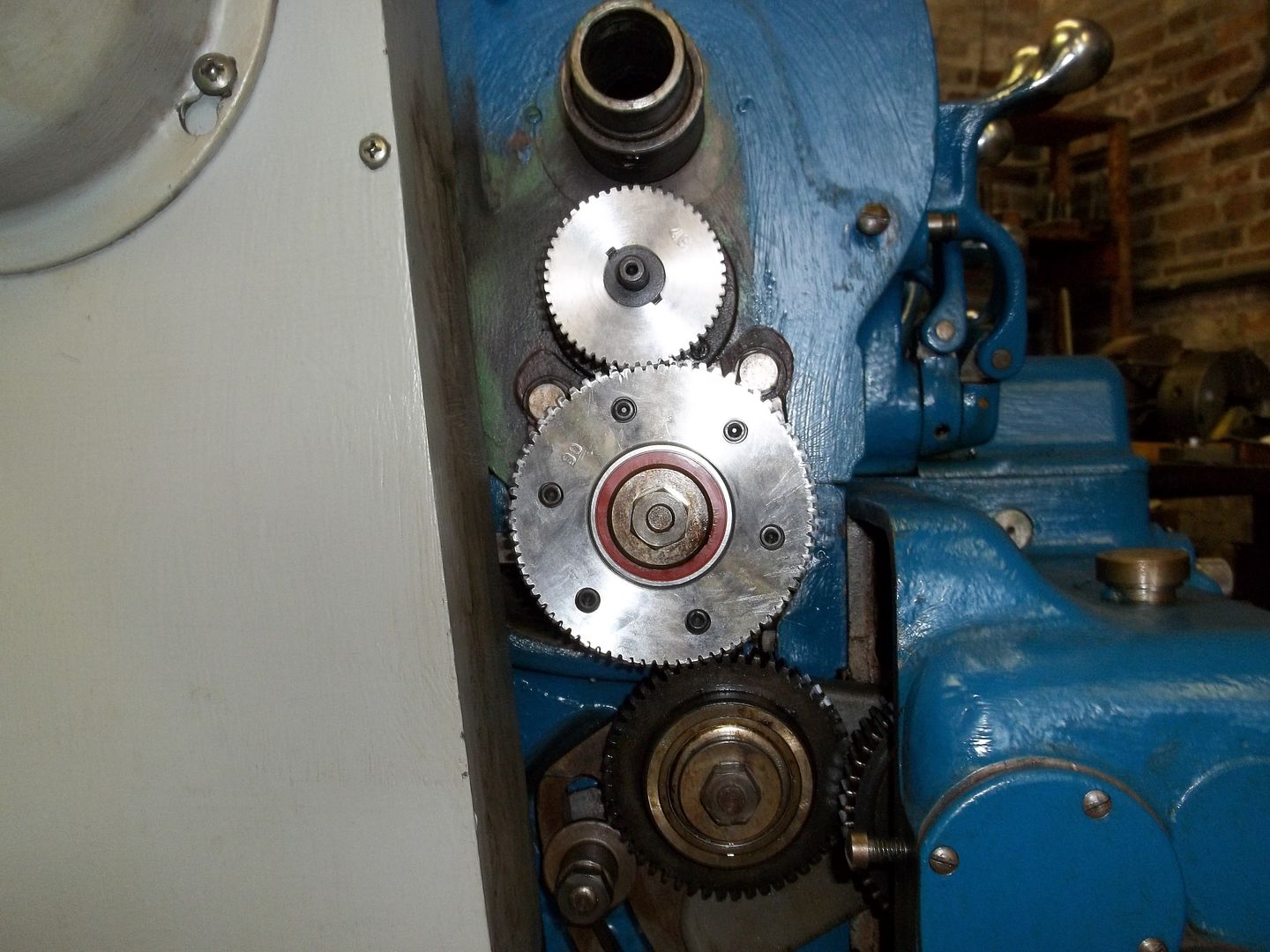

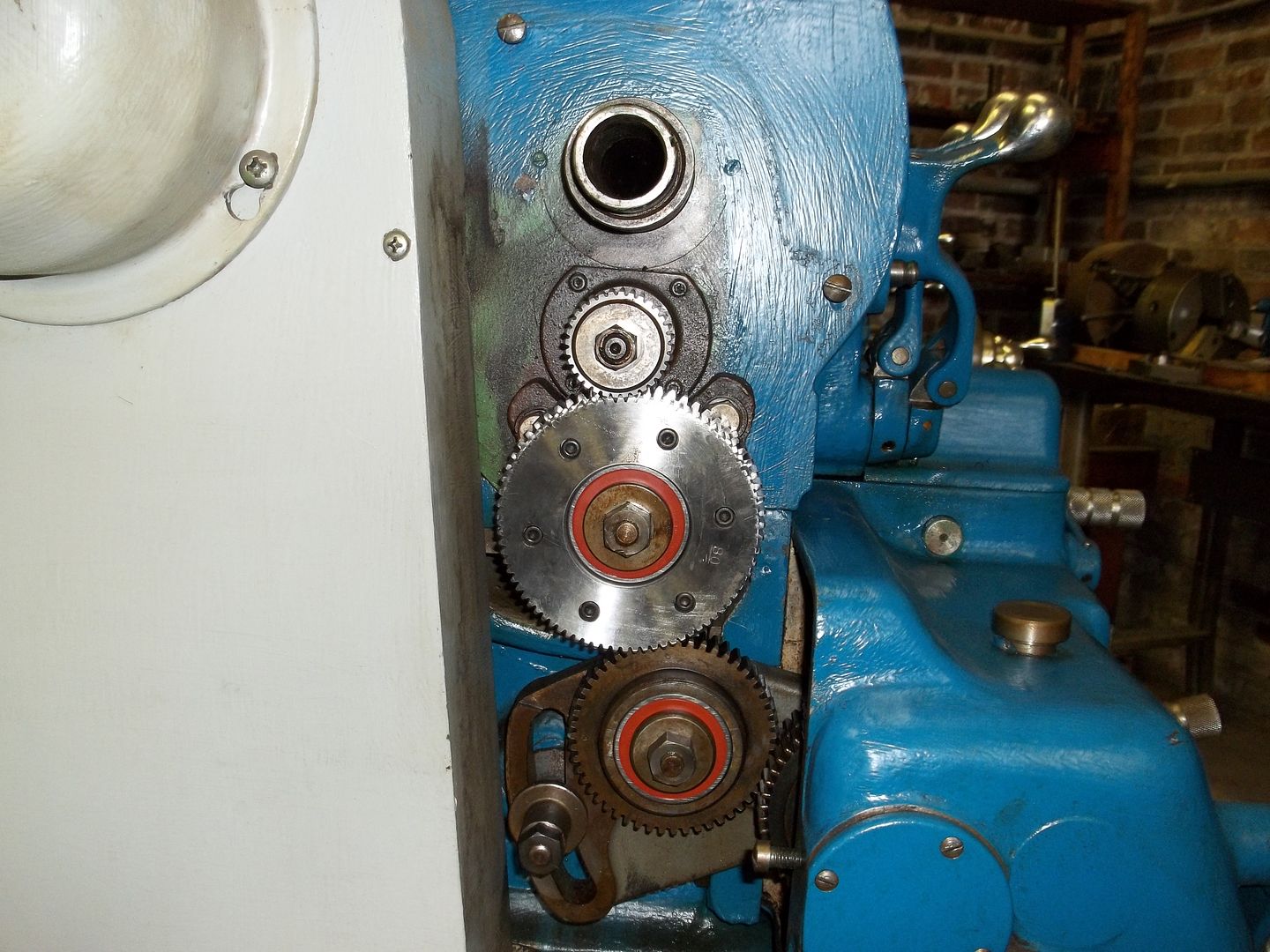

Well, I thought the SE 60 was going to be easier than the CK, but I had a little surprise. It seems that the person, who shall not be named, that last worked on the end gearing 3 years ago Loctited the the bearings to the shaft to keep the inner race from spinning on the shaft. Had to take the entire quadrant assembly off the lathe, and get the gear puller out. It came off, but not easily. Then after getting things cleaned up and the quadrant remounted, went to install the compound gear, but the outer bearing covered up the snap ring groove on the shaft. Needed about 1/8" more. Off comes the compound gear, get the bearing out, removed the outside internal snap ring, got the 1/8" needed, and reinstalled the bearing, then back on the lathe. Other than that, it was easy.

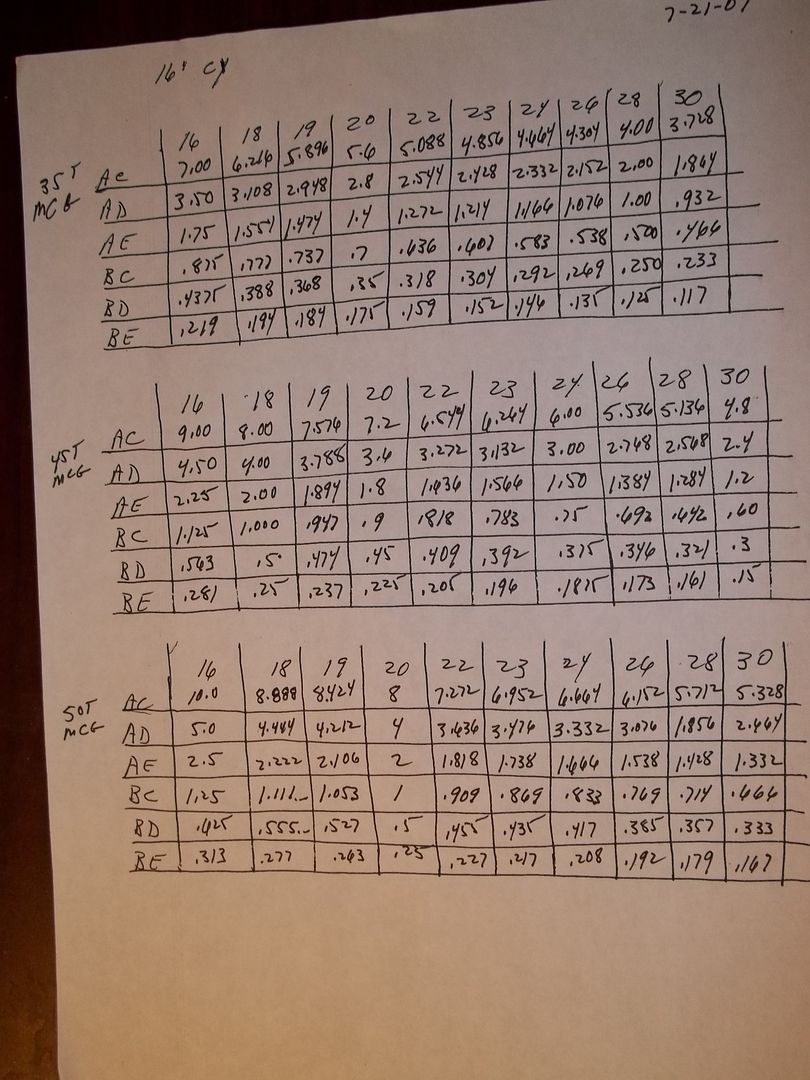

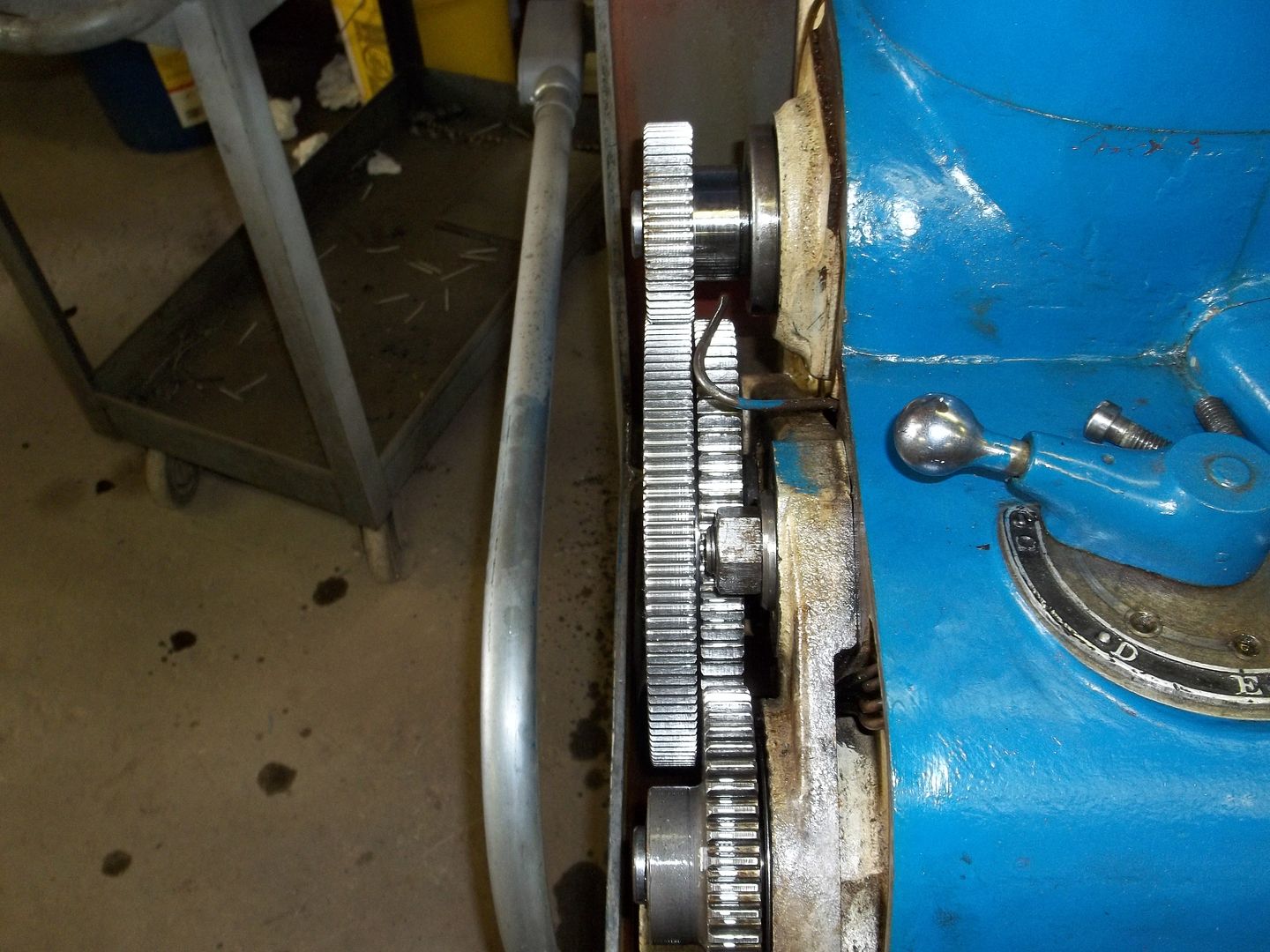

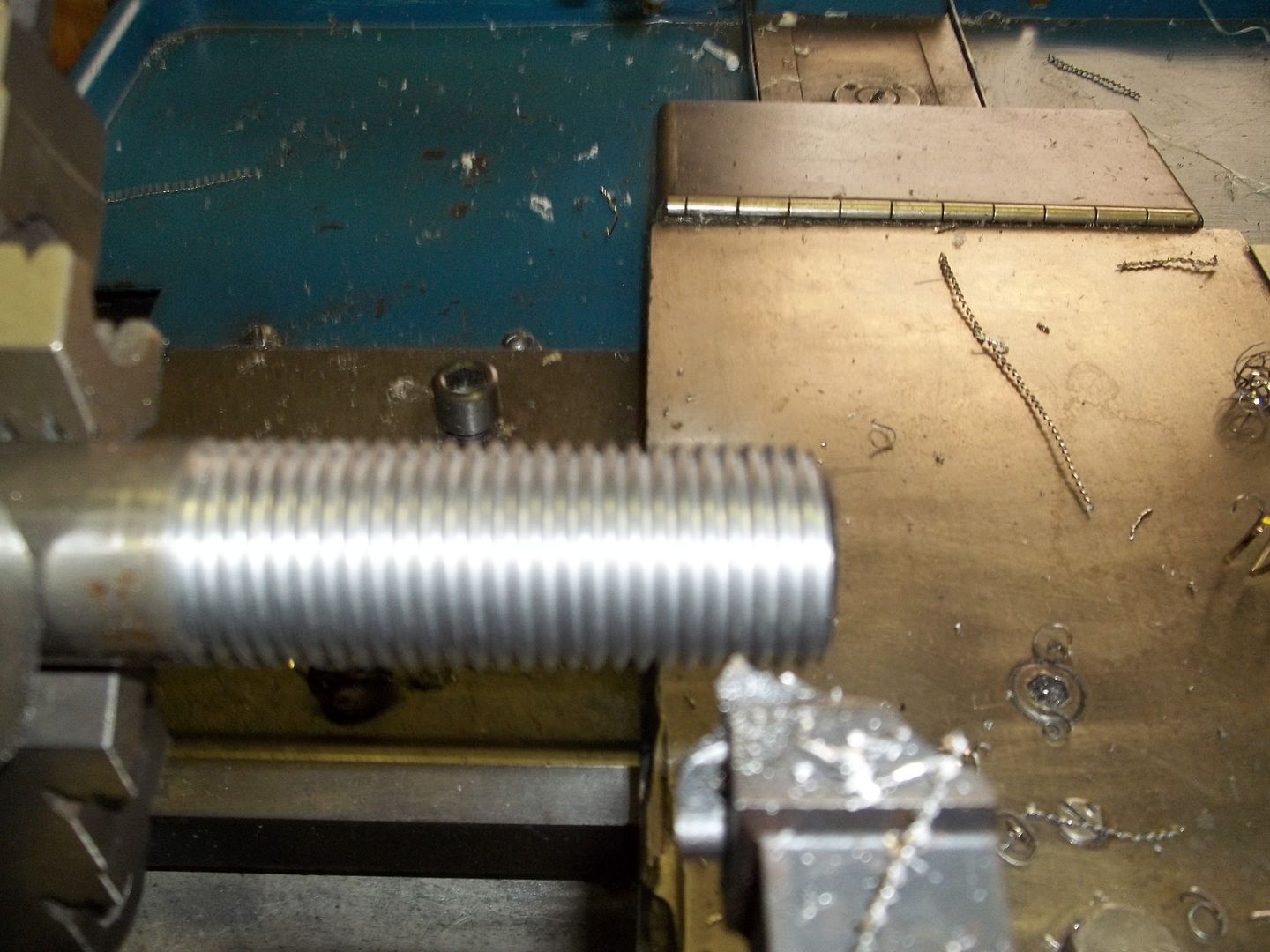

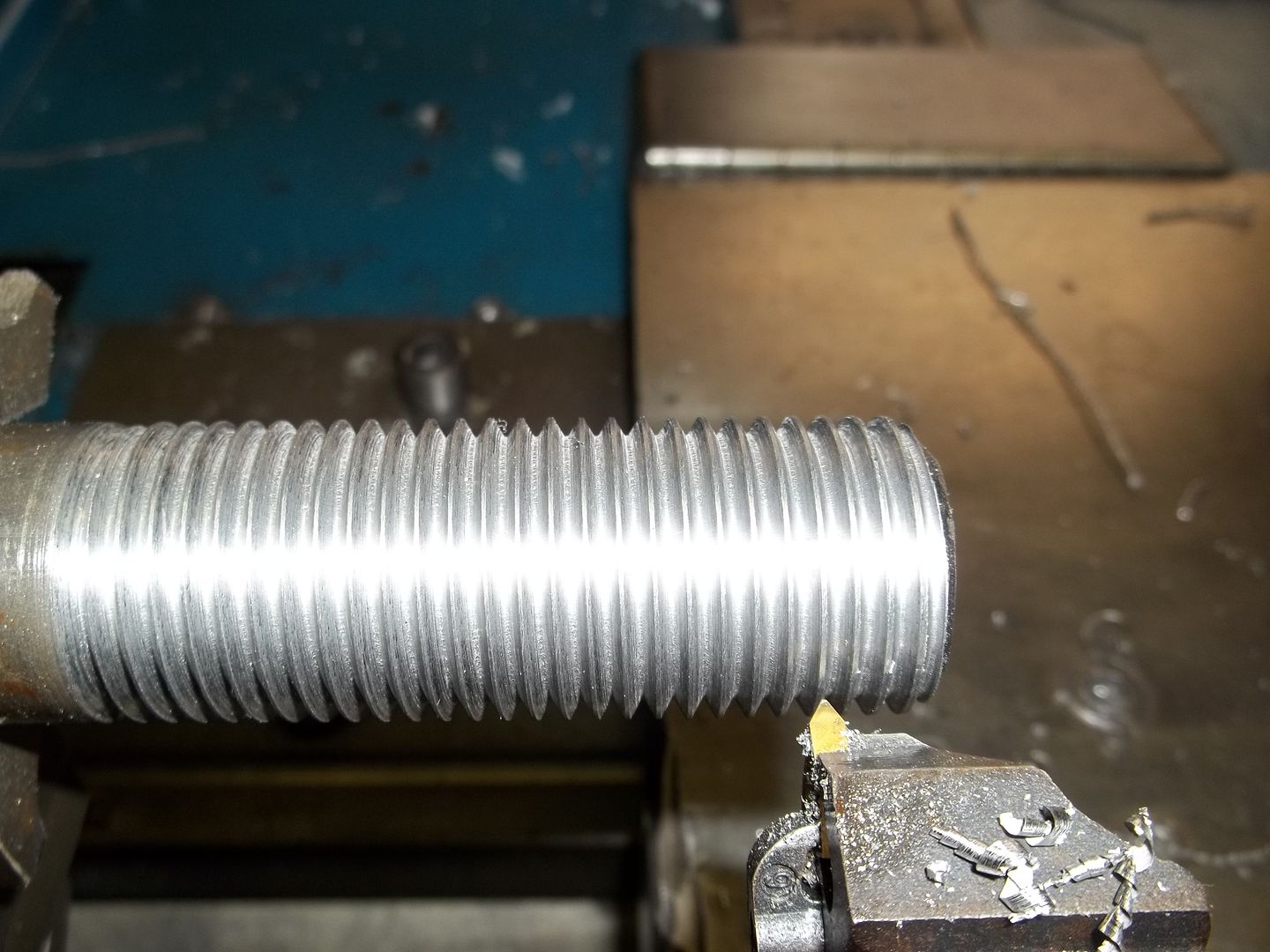

Cut 2 threads using the 50 T MCG, 1.25 and 3 MM on a 1-3/16" 1045 shaft. No coolant was used, and I was pleasantly surprised how well the threads looked. RPM was approx 250, that speed on the speed chart is mangled, so I'm guessing.

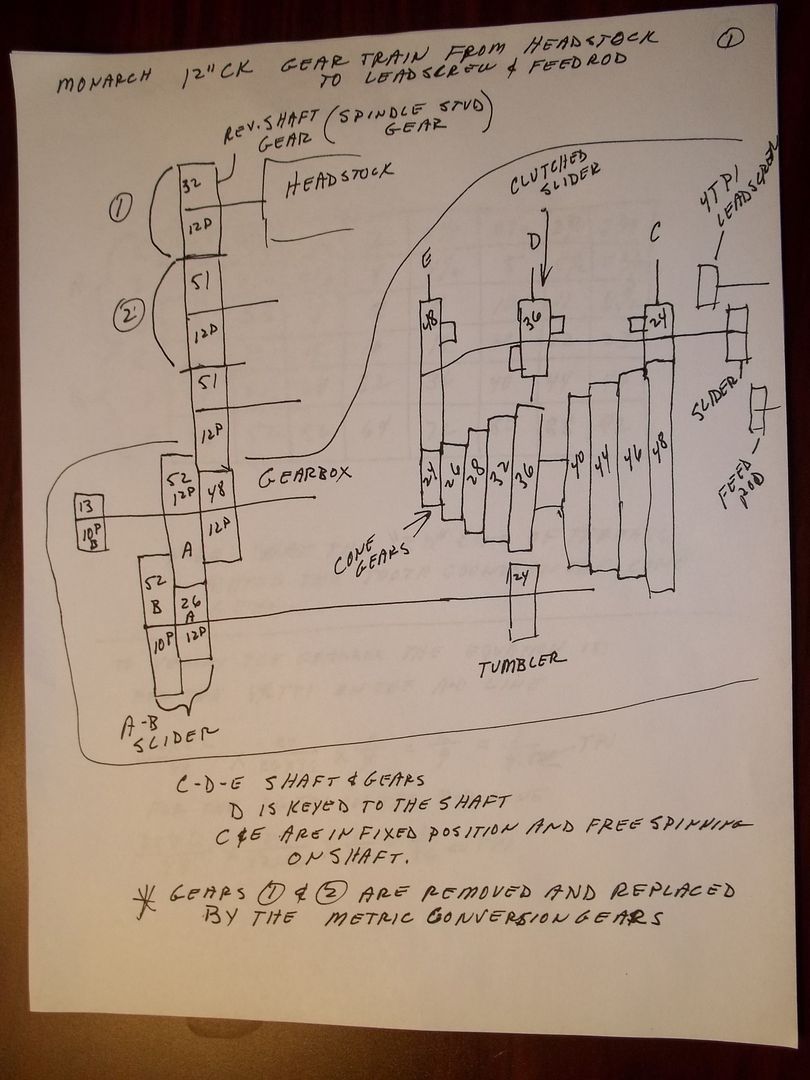

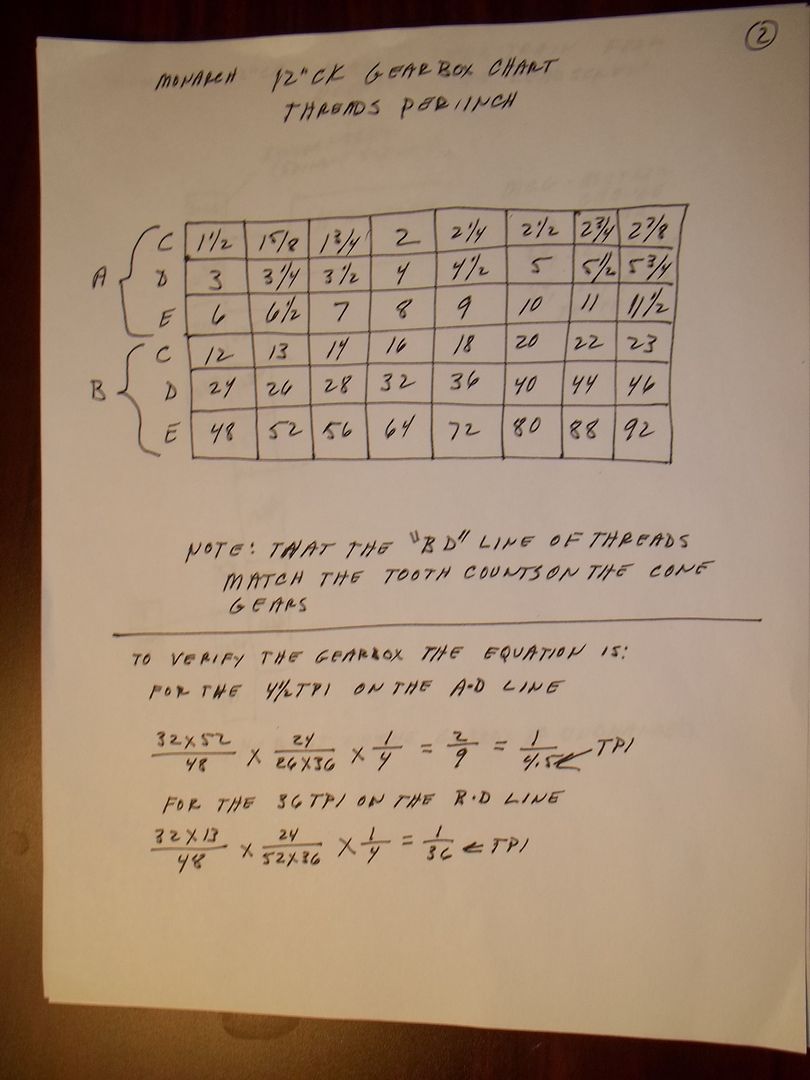

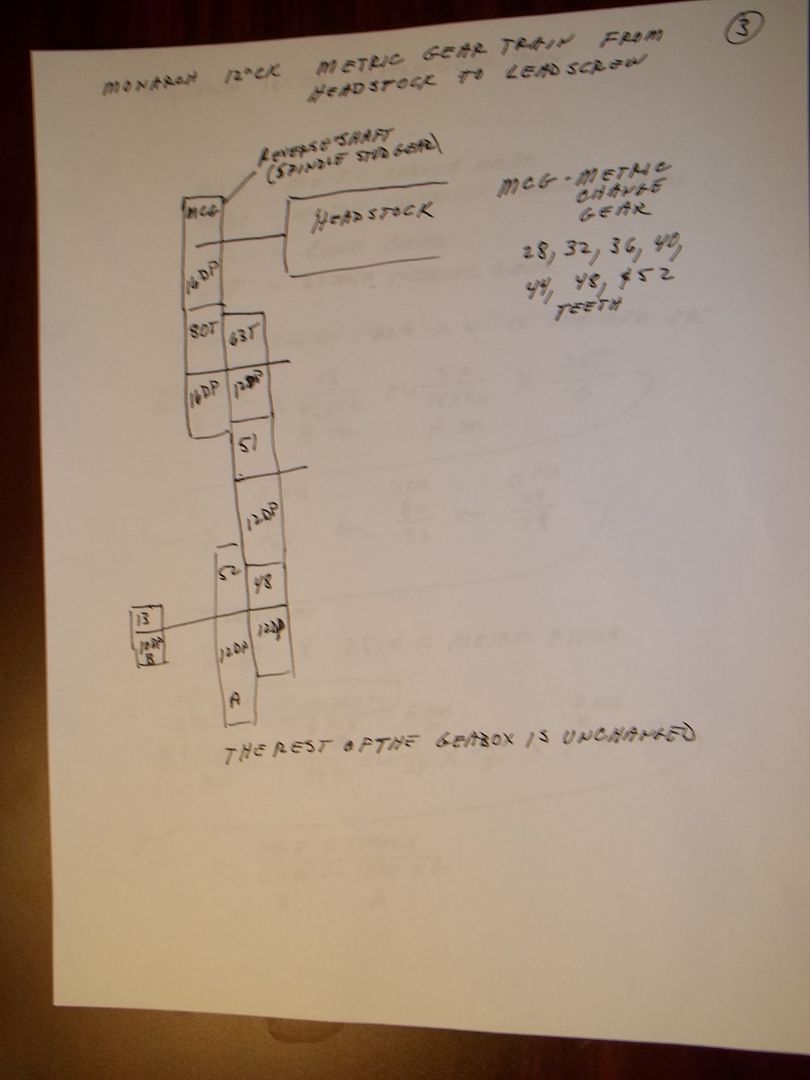

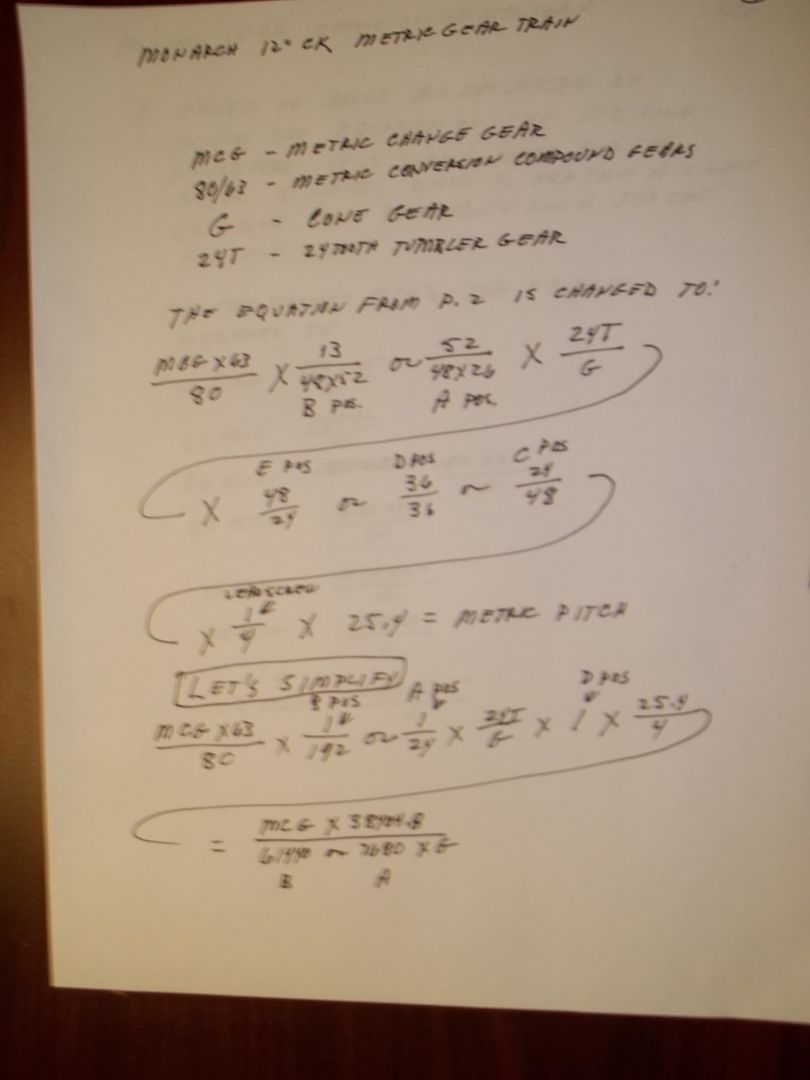

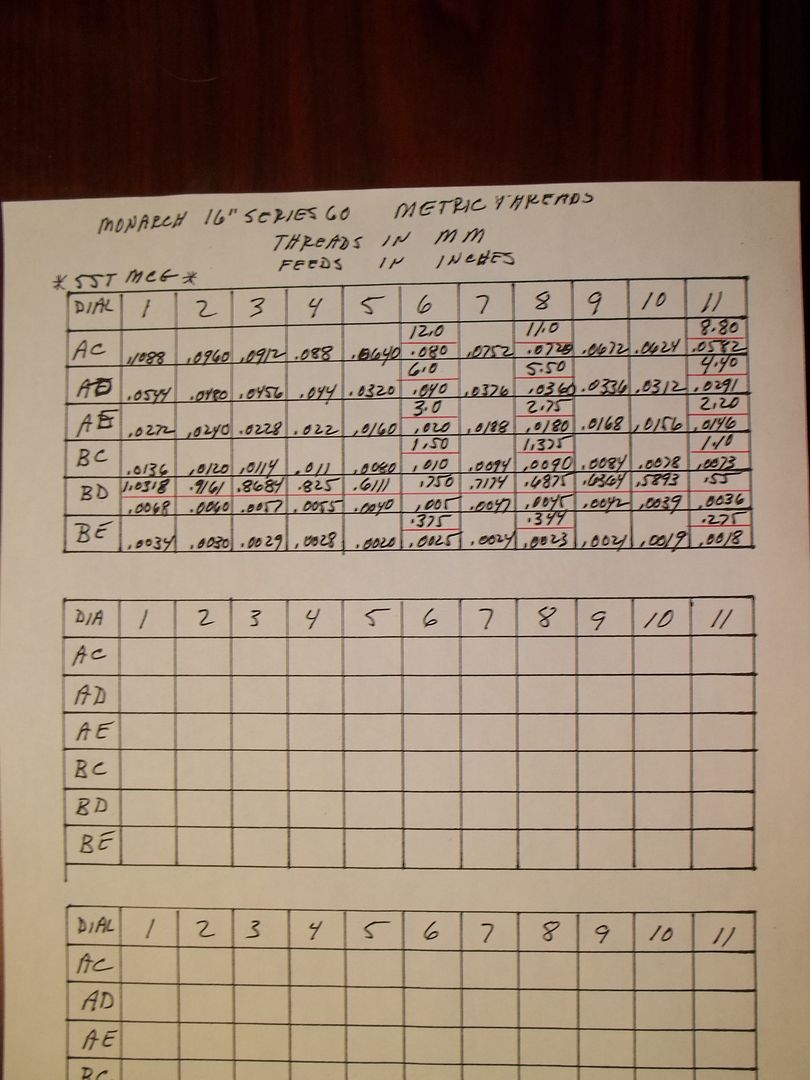

I think the pictures are self explanatory.

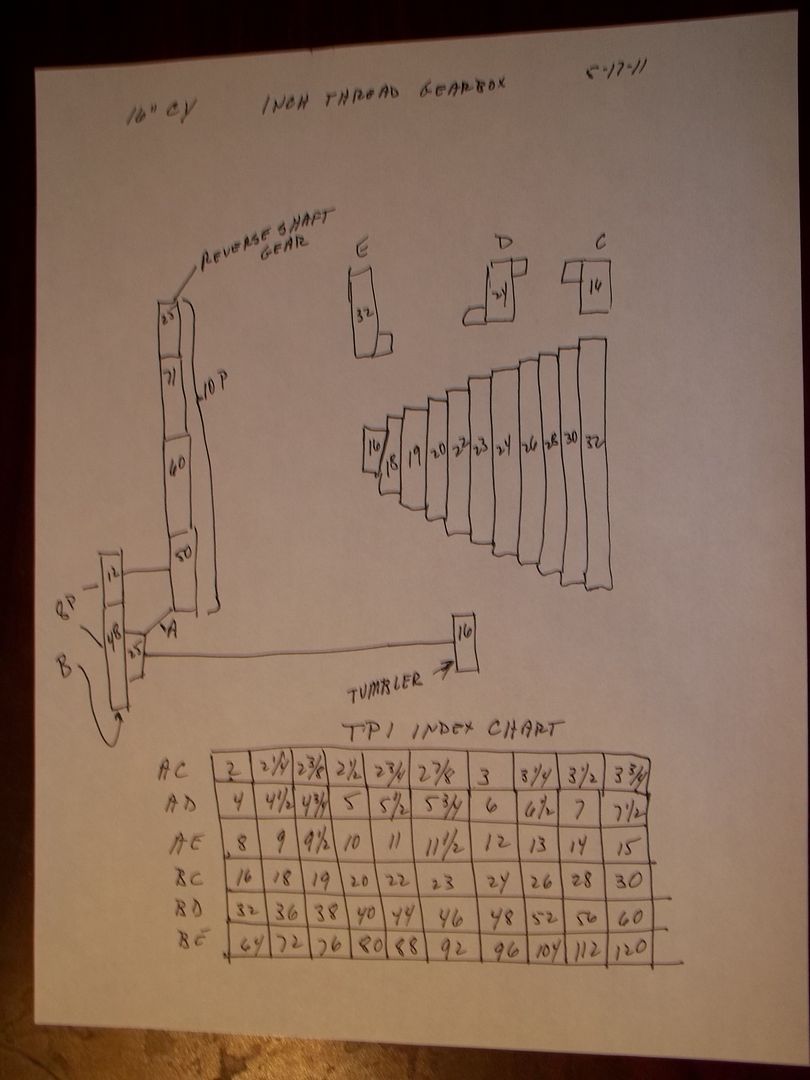

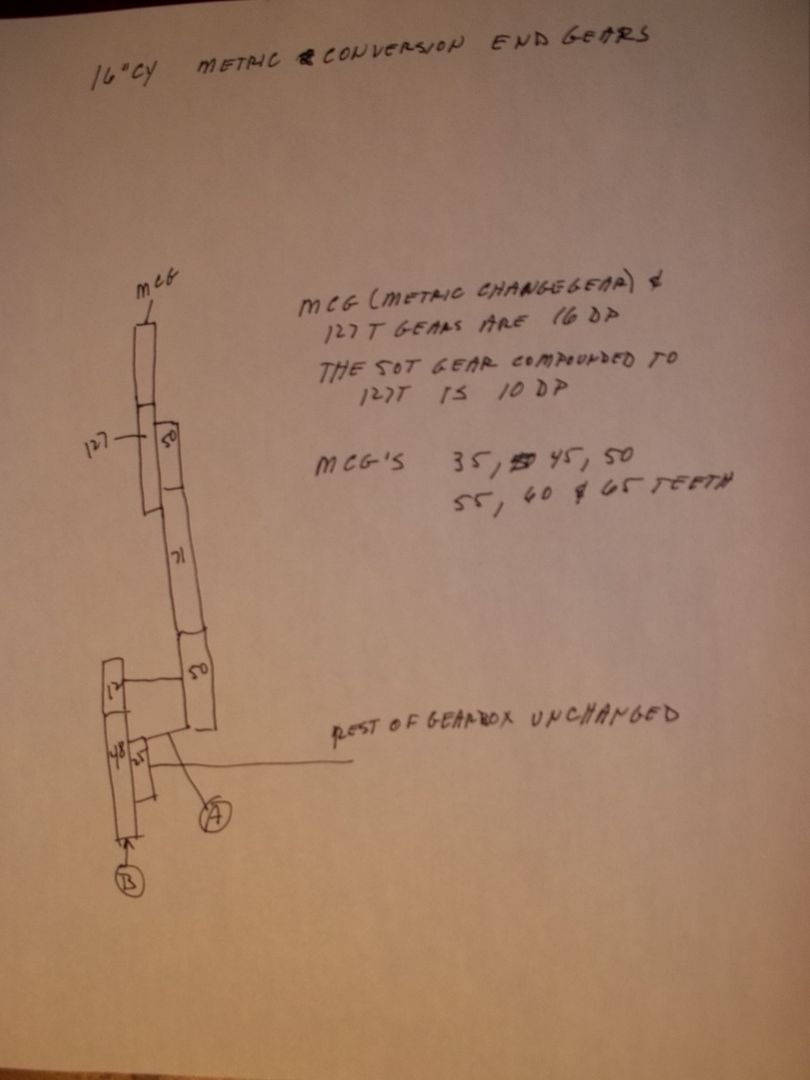

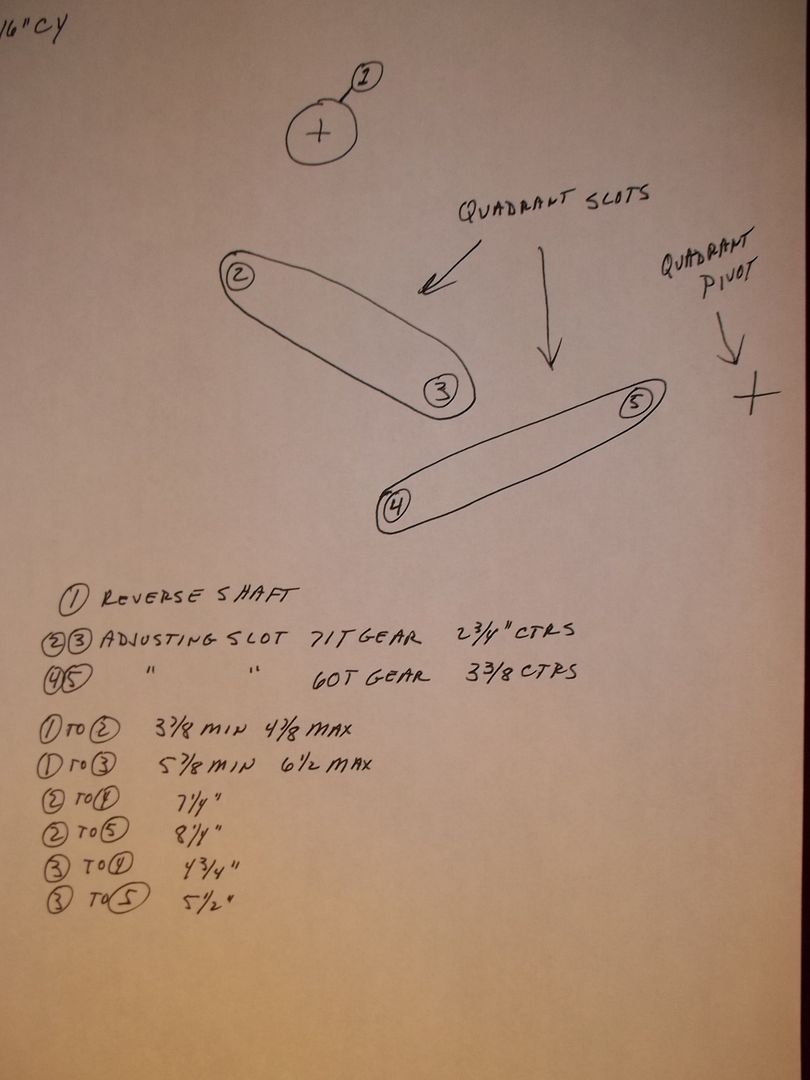

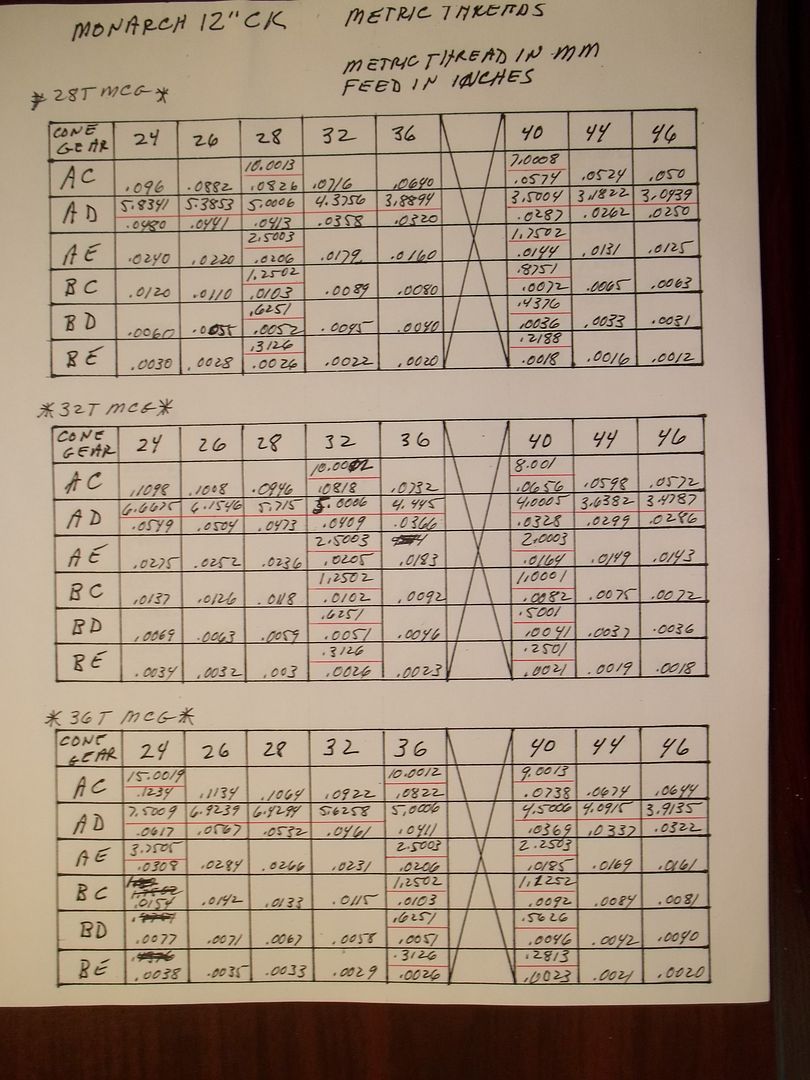

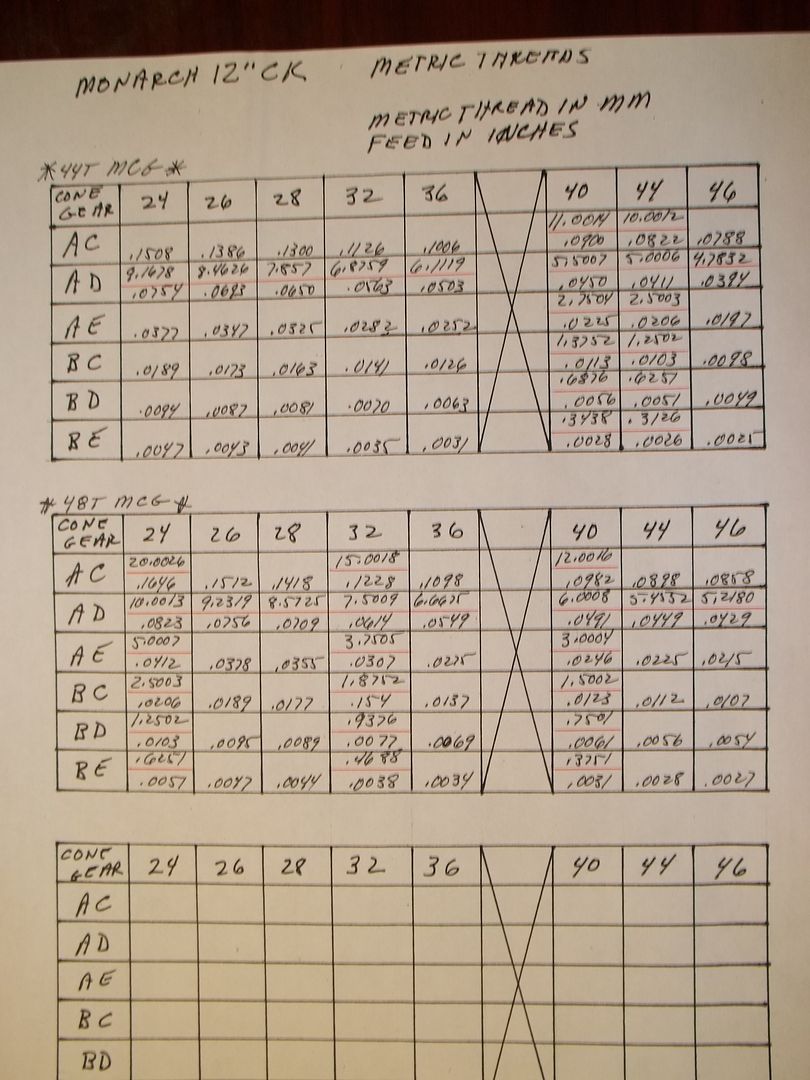

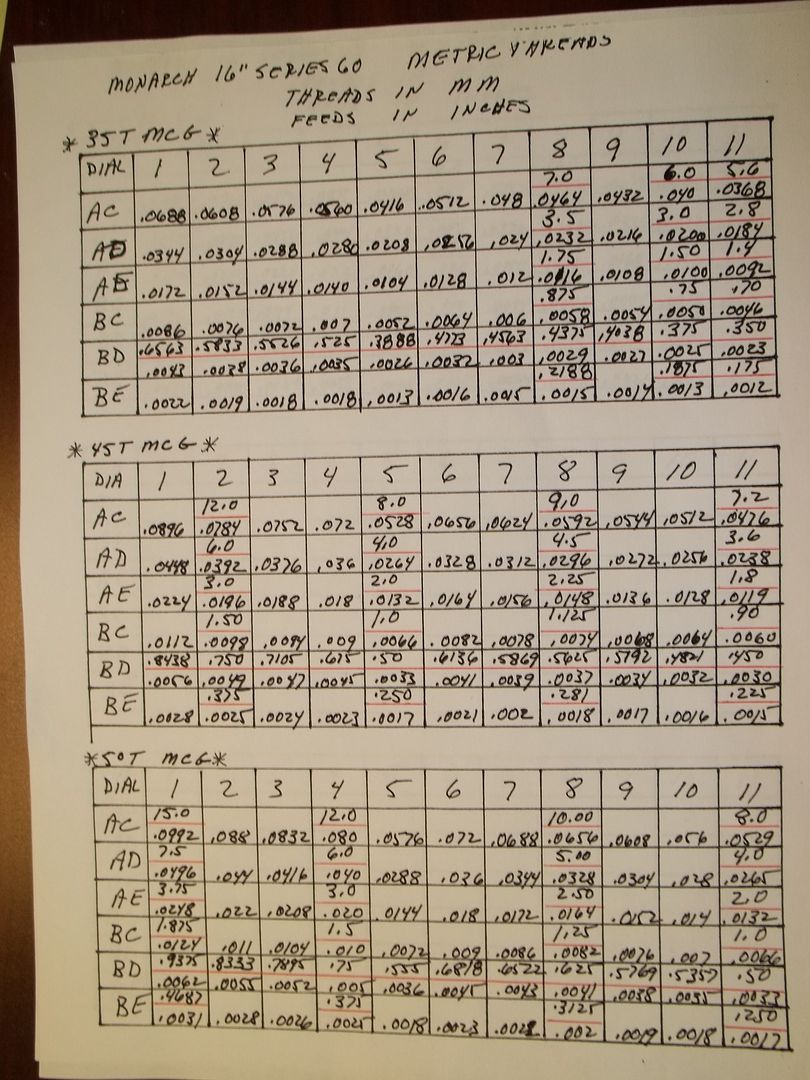

I have yet to clean up the charts for the SE 60, but they are very similar to the ones for the CY.

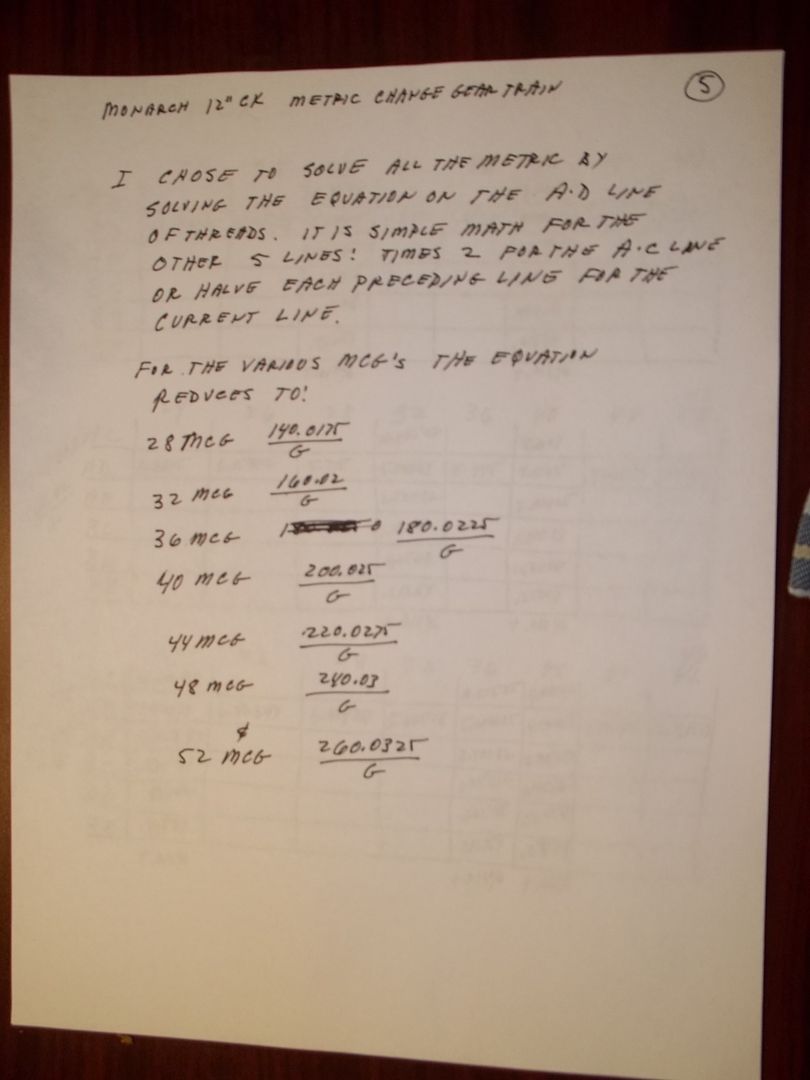

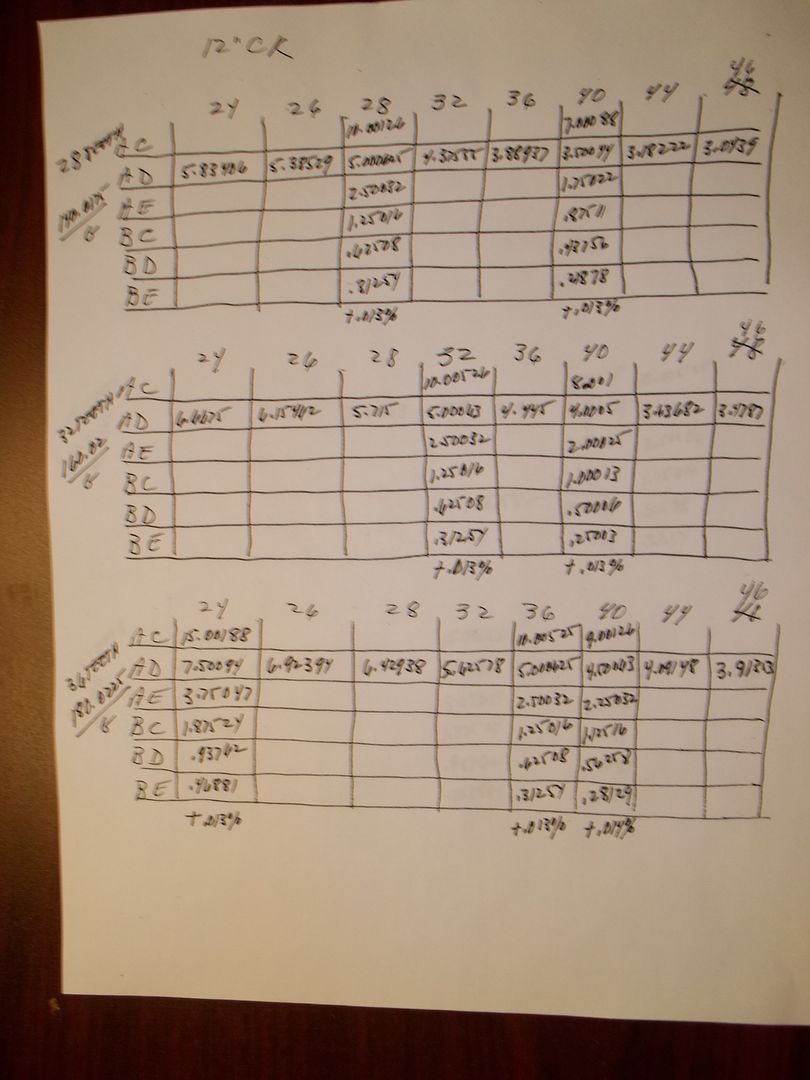

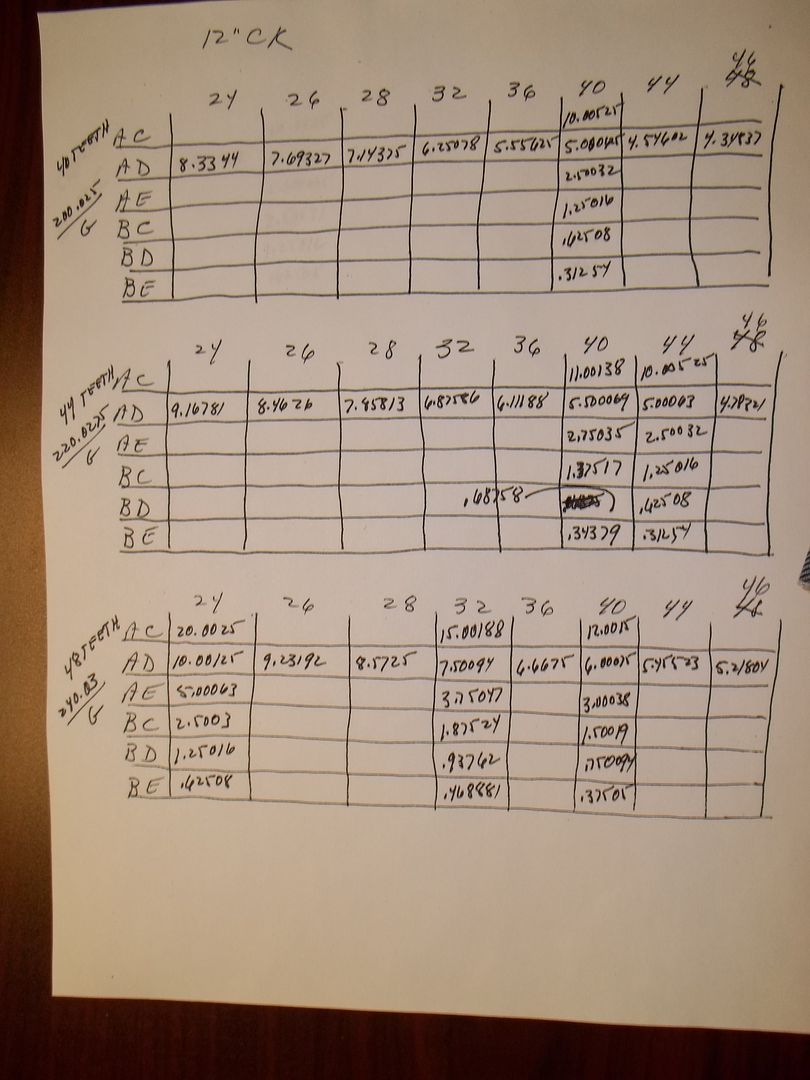

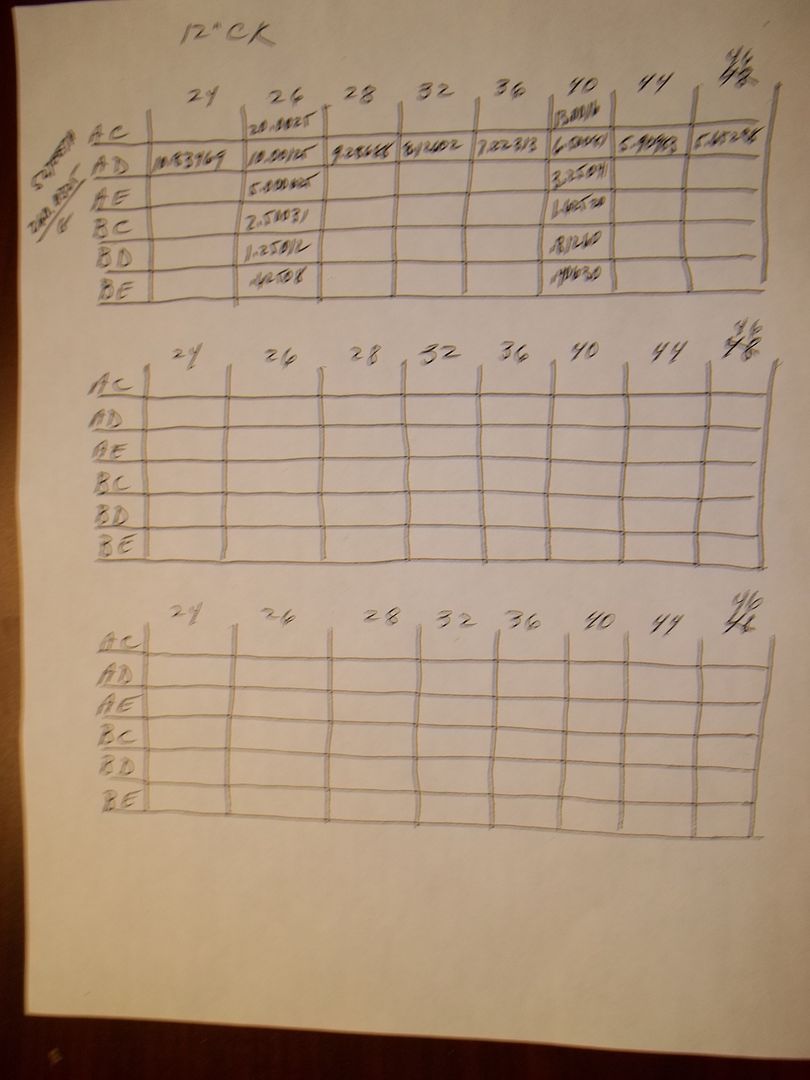

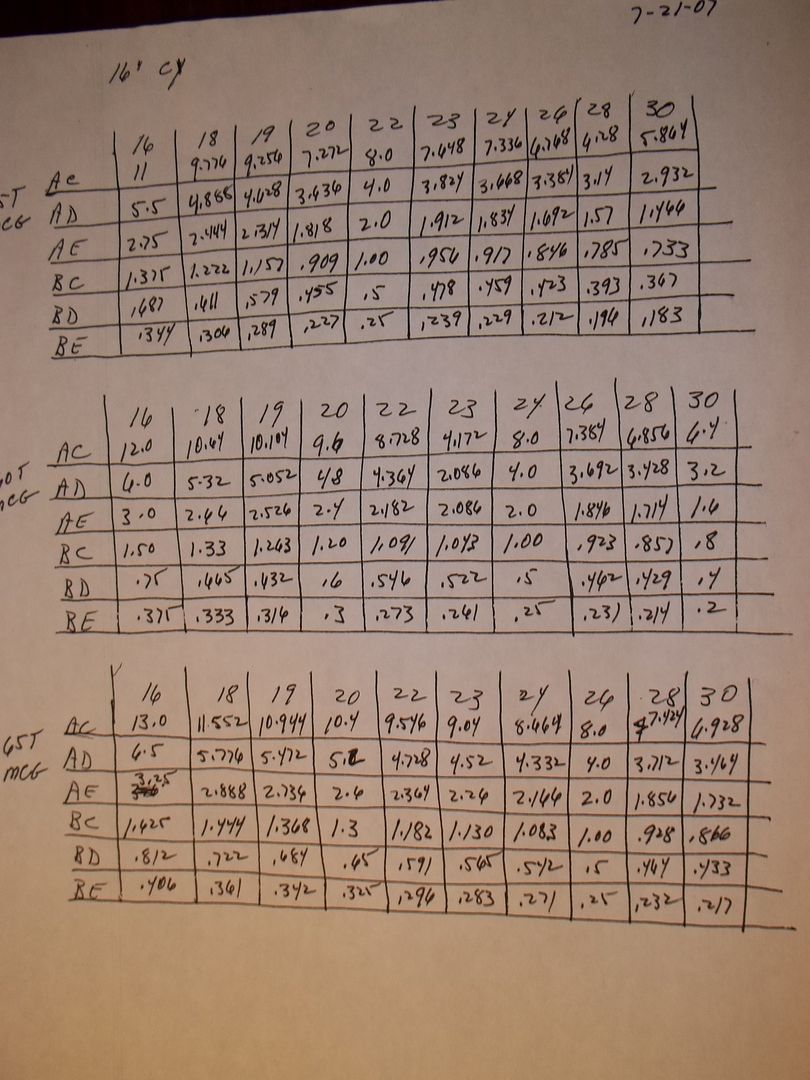

I made spread sheets for all the gears, for the CK and SE 60, mainly to see how many duplications there are, and which gears I didn't truly need. If you look at the charts above, there are quite a few threads that aren't listed in Machinery's Handbook, after listing all the metric threads I could find, and there are quite a few. This included the minature, Lowenhertz, Trapezoidal, and regular. I think my final selections have a comprehensive coverage. I'm not concerned about the "No-See'um" threads, I just have a very hard time envisioning cutting anything under .5 MM on these "big" machines. Conversely, I don't think I'm going to be cutting those 20 MM Trapezoidals either. I'm just looking for the common metric threads.

In a few days I'll post the revised charts, hopefully with the feed rates.

If you're concerned about the accuacy of the threads for the CK, with the 80/63 compound gear, the threads listed are carried out to the 4th decimal place. May not be good enough for a leadscrew, but they are very close.

Harry