How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

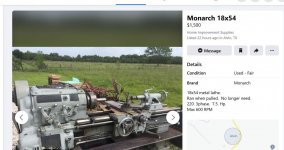

Monarch 18 x 54 lathe

- Thread starter GregSY

- Start date

- Replies 15

- Views 2,341

texasgeartrain

Titanium

- Joined

- Feb 23, 2016

- Location

- Houston, TX

Dammit, Alvin is 5 minutes from me. I really don't need more temptations atm. What I could use right now is a nice little cocaine habit to save a little money over buying tools and machines.

16CY 600 rpm, listed top speed. Built in 1942. Two pics of tags, GregSY posted the only pic of machine.

16CY 600 rpm, listed top speed. Built in 1942. Two pics of tags, GregSY posted the only pic of machine.

johnoder

Diamond

- Joined

- Jul 16, 2004

- Location

- Houston, TX USA

Lead screw reverse (on apron) - such stuff doesn't grow on trees

Last edited:

texasgeartrain

Titanium

- Joined

- Feb 23, 2016

- Location

- Houston, TX

Lead screw reverse - such stuff doesn't grow on trees

LALALALALALALA. . . I can't hear you !

Ok, maybe for posterity's sake, if its still around, I'll go take some pics to post, its real close to me.

But that's it ! Just pics !

cranium

Hot Rolled

- Joined

- Feb 18, 2013

- Location

- Crockers Nub, NC

It's listed under home improvement supplies.

My wife will get a kick out of that.

My wife will get a kick out of that.

rabler

Cast Iron

- Joined

- May 25, 2020

- Location

- Rural S.W. Indiana

Just finishing up reworking a 12x30 1944 CK. Still have a fairly beaten up 10EE to work on. Never the less, I've been pondering a 54" or 78" bed Monarch. It's an addiction. Would like to see more pics, I can't tell if this one has a taper attachment.

There is a 16x54 Model K a few hours away from me on FB, but really inclined toward a model 61. Missed the one recently listed on the For Sale forum here, and still kicking myself for that. And I do have space in a separate building with a 200amp service separate from the house. There's a few 61's listed on E-bay, but I'd like to find something I can look at before committing to, and E-bay makes that difficult to protect their commission.

There is a 16x54 Model K a few hours away from me on FB, but really inclined toward a model 61. Missed the one recently listed on the For Sale forum here, and still kicking myself for that. And I do have space in a separate building with a 200amp service separate from the house. There's a few 61's listed on E-bay, but I'd like to find something I can look at before committing to, and E-bay makes that difficult to protect their commission.

mjr6550

Aluminum

- Joined

- Oct 7, 2012

- Location

- Lansdale, PA

Just saw this listing today.

Giana GFP24

Swing 129

Lngt 531

HIS 5.9

Hor 73

The swing and length are inches. That's a big boy's lathe.

Giana GFP24

Swing 129

Lngt 531

HIS 5.9

Hor 73

The swing and length are inches. That's a big boy's lathe.

texasgeartrain

Titanium

- Joined

- Feb 23, 2016

- Location

- Houston, TX

So I took a little ride. . .Turns out its about 10-15 minutes from my house. I gotta tell you, my heart was beating a little. If this thing turned out to have a taper attachment, and be in decent shape. . . Dear god, I don't have the space or time right now. . . I was stressing.

Turns out I'm feeling a lot of relief . It's rough. Definitely you are going the whole way, tear down project, with extra repairs type project. Plus no taper attachment.

. It's rough. Definitely you are going the whole way, tear down project, with extra repairs type project. Plus no taper attachment.

The details hard and fast: Rough, its a project. They can't load it on a truck or trailer. No taper attachment, steady rest, or follower rest. No other tooling, what you see is what there is. Missing left clutch cover. Carriage, crossfeed, and rest all need two hands to turn them. Ways not totally wrecked, but its 78 years old. Spindle spins, feels right. Speeds that I checked are all there. QCGB gears are intact. Claims the $1500 is firm. 7.5 hp.

The entire machine has been soaked down with a preservative type oil/grease. Everything. Every inch and surface. They double checked, then got a fire hose to blast it down some more. And for those of you not from the South, its love bug season, and they have landed all over the machine, in the oil.

Other details will probably hit me as I post pics.

Turns out I'm feeling a lot of relief

. It's rough. Definitely you are going the whole way, tear down project, with extra repairs type project. Plus no taper attachment.

. It's rough. Definitely you are going the whole way, tear down project, with extra repairs type project. Plus no taper attachment.The details hard and fast: Rough, its a project. They can't load it on a truck or trailer. No taper attachment, steady rest, or follower rest. No other tooling, what you see is what there is. Missing left clutch cover. Carriage, crossfeed, and rest all need two hands to turn them. Ways not totally wrecked, but its 78 years old. Spindle spins, feels right. Speeds that I checked are all there. QCGB gears are intact. Claims the $1500 is firm. 7.5 hp.

The entire machine has been soaked down with a preservative type oil/grease. Everything. Every inch and surface. They double checked, then got a fire hose to blast it down some more. And for those of you not from the South, its love bug season, and they have landed all over the machine, in the oil.

Other details will probably hit me as I post pics.

Last edited:

texasgeartrain

Titanium

- Joined

- Feb 23, 2016

- Location

- Houston, TX

texasgeartrain

Titanium

- Joined

- Feb 23, 2016

- Location

- Houston, TX

texasgeartrain

Titanium

- Joined

- Feb 23, 2016

- Location

- Houston, TX

The handwheel in apron to drive carriage up and down ways, somethings wrong inside. I can move handwheel and shaft up and down about a 1/4".

I don't see anything abnormally wrong with dovetail for compound, but a shim is sticking out of gib. And every hand wheel is tight. Two hands to turn it tight, carriage, crossfeed, rest, tail stock spindle.

No t/a:

I don't see anything abnormally wrong with dovetail for compound, but a shim is sticking out of gib. And every hand wheel is tight. Two hands to turn it tight, carriage, crossfeed, rest, tail stock spindle.

No t/a:

Last edited:

texasgeartrain

Titanium

- Joined

- Feb 23, 2016

- Location

- Houston, TX

texasgeartrain

Titanium

- Joined

- Feb 23, 2016

- Location

- Houston, TX

Thanks for the recon...I feel better now, too!

IMO, Texas is NOT good country for buying used machinery....it seems by the time a lathe / mill reaches the South, it's been rode hard and put up wet - or will be soon.

Yea, its true. Even with the Houston area having a lot of industry, you just don't see the same amount of available machines like the North East coast, Rust Belt, etc. The machines I've found here were like accidental finds, I wasn't looking for them specifically.

If you have long term patience, and can wait, things do pop up. But this lathe is almost priced right for our area. At $1500 its a project lathe, where if it were in decent condition it would have been a real bargain.

One up side is, I feel a whole lot better about the 61 series I bought and shipped from Ohio. The shipping cost alone was $1500 and change ! It does need work, but all in all, I feel like its real solid.

A funny thing though, a Monarch 16CY has been a coveted machine for me. An outfit I did some work for had one. It was the first gear head lathe I got a real good look at. I thought it was so cool, and the attention to detail on a lot of small or minor items was real nice. It's also one of a few machines I think look good painted green.

Similar threads

- Replies

- 1

- Views

- 632

- Replies

- 14

- Views

- 687

- Replies

- 4

- Views

- 325