nt1953

Hot Rolled

- Joined

- Sep 4, 2004

- Location

- Huntsville, Alabama

The worm assembly on my Monarch Model 61 was worn out, and after looking at its design, I decided to make repairs and to redesign the assembly.

Before I go any further, I want to thank Cliff Holm, a member here, who sent me a worm, driver, worm wheel, and half nuts. The condition of my worm and worm wheel were comparable to Cliff’s, but his half nuts were much much better than mine. Thank you Cliff.

Using Monarch’s nomenclature, the worm assembly consists of a collar, three bronze bushings, a driver, a driver plate, and a worm. The picture below shows the parts less the collar and bronze bushings.

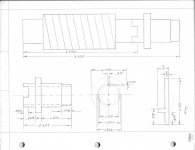

My idea was to redesign the assembly pictured by repairing/redesigning the worm, and making a new driver that combined the driver with the driver plate (the two lower parts in the picture). I also planned on making the center bronze bushing longer to better support the joint between the driver and the worm.

The drawing below reflects the design changes I made and the repairs/redesign of the worm.

Before I go any further, I want to thank Cliff Holm, a member here, who sent me a worm, driver, worm wheel, and half nuts. The condition of my worm and worm wheel were comparable to Cliff’s, but his half nuts were much much better than mine. Thank you Cliff.

Using Monarch’s nomenclature, the worm assembly consists of a collar, three bronze bushings, a driver, a driver plate, and a worm. The picture below shows the parts less the collar and bronze bushings.

My idea was to redesign the assembly pictured by repairing/redesigning the worm, and making a new driver that combined the driver with the driver plate (the two lower parts in the picture). I also planned on making the center bronze bushing longer to better support the joint between the driver and the worm.

The drawing below reflects the design changes I made and the repairs/redesign of the worm.

and/or perspective or camera angle.

and/or perspective or camera angle.