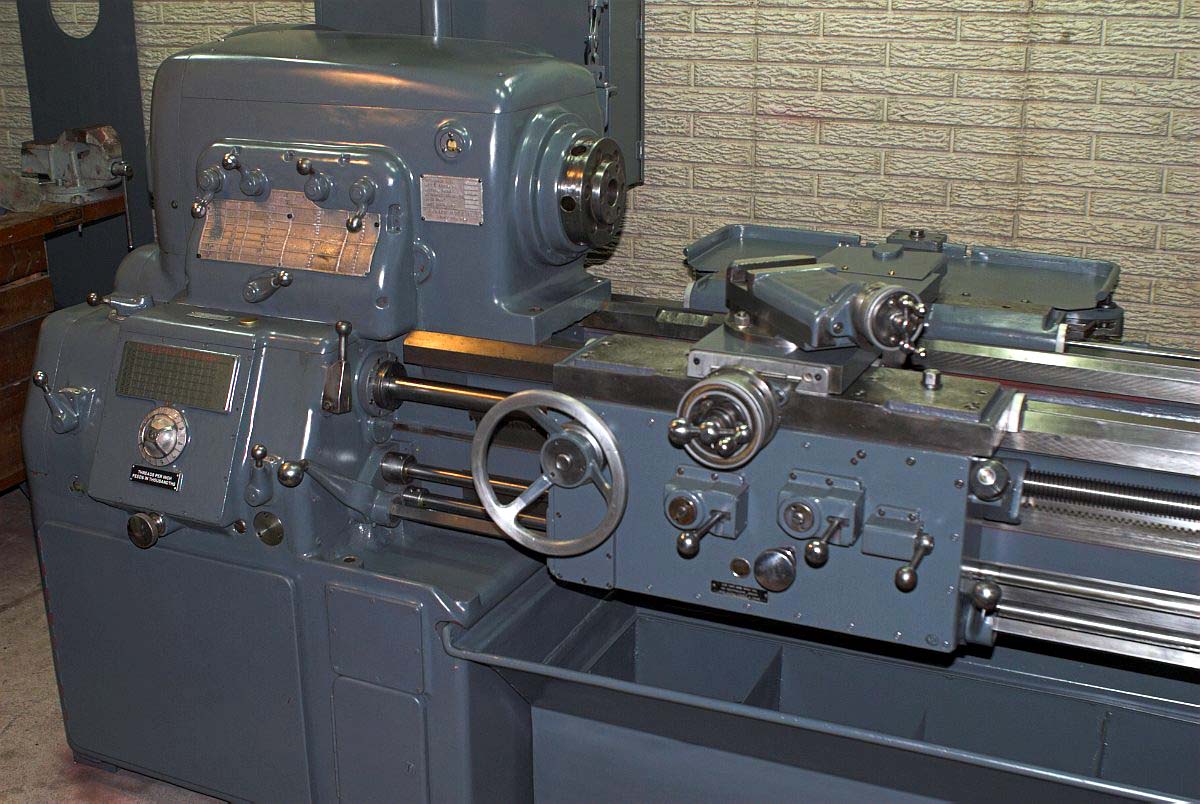

The ways are pretty much fresh ground so thats a plus on the lathe. We still got to tool it up. It did come with a 3 jaw.

Pretty amazing how tiny the bore is for that size of a machine.

I looked at the serial and there is no HT or AT for the tracer option. Cant figure out what that support casting off the tail of the bed was originally used for. Plus there are holes along the back of the bed drilled and tapped down the length like there was something mounted there. The lead screw passes through the bearing block on the tail end and becomes a 3/4" shaft with a keyway. Also there appears to have been some sort of rod that ran from the threading gearbox down the length of the bed through the apron and into the casting that supports the leadscrew and feed rod.

TechShop does take a bit of insurance to make it go. That is the main issue. We wanted to have an auto section but that got nixed by the insurance company.

TechShop is kinda franchised but pretty much all we are getting from the Menlo Park location is the name and maybe some curriculum. Pretty much we are on our own.

So all you need is money! Realistically you need about a half mil to get it going. Since we are not using any banks to fund this thing we are looking for investors. $25k investment gets you 10% back per year for 10 years and a lifetime membership.

The monarch we traded for membership. We did pay for the rigging to get the thing in here though. That was $1100.

There are a few TechShop like places scattered all around the country. In the Bay area there is the Crucible and one that I cant remember the name of that is a woodworking shop. Heres another one in Colorado:

http://www.clubworkshop.com/

Our rates are $125 a month or $1200 a year. We will be offering bunches of classes. Looks like I have been stuck teaching the CNC basics class.