Jaymce

Aluminum

- Joined

- Jan 6, 2013

- Location

- New England

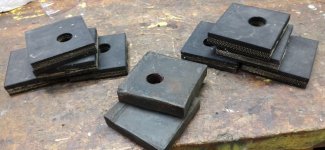

Picked up a new to me 1946 Monarch 10ee. Just in the process of cleaning it up and can not figure out what the pump assembly located under the tail stock is? Coolant pump?

I would appreciate any help. Makes a bunch of noise and new rubber mounts. If it's a coolant pump I don't do production ad would be ok with it being disconnected.

Thanks in advance for any help.

Jay

Sent from my SM-G950U using Tapatalk

I would appreciate any help. Makes a bunch of noise and new rubber mounts. If it's a coolant pump I don't do production ad would be ok with it being disconnected.

Thanks in advance for any help.

Jay

Sent from my SM-G950U using Tapatalk