M. Moore

Titanium

- Joined

- Jun 8, 2007

- Location

- Vancouver Island, B.C. Canada

First post for the DSG guys (or anybody).

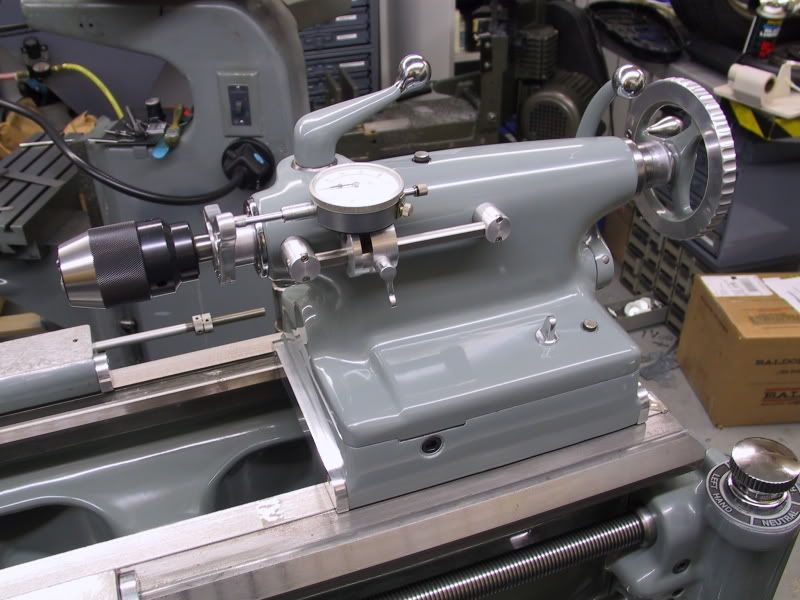

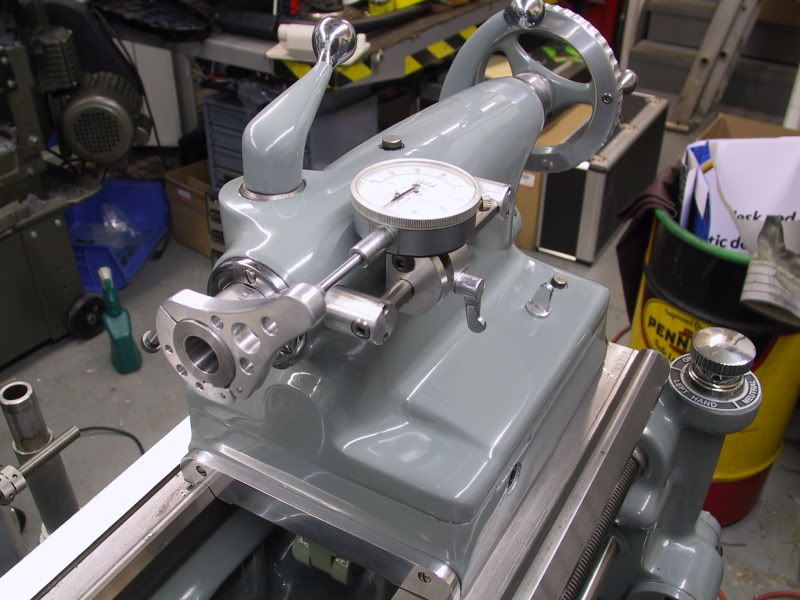

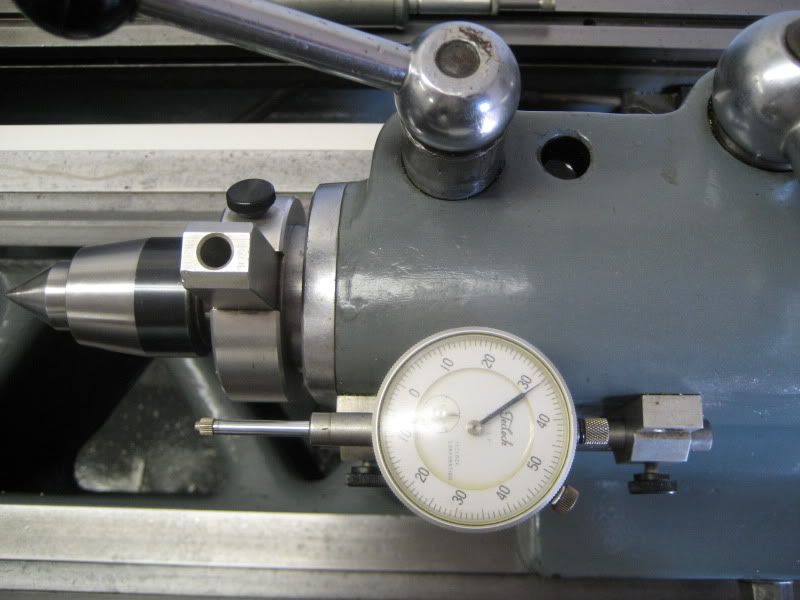

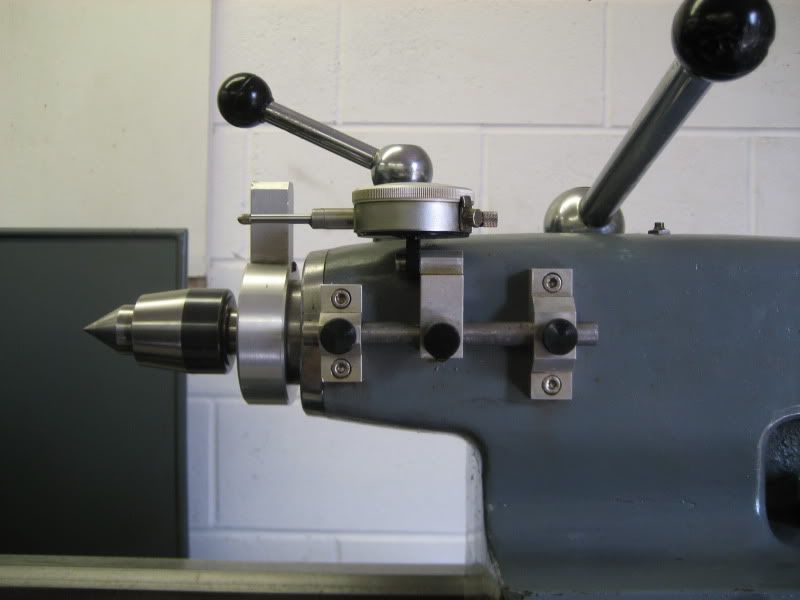

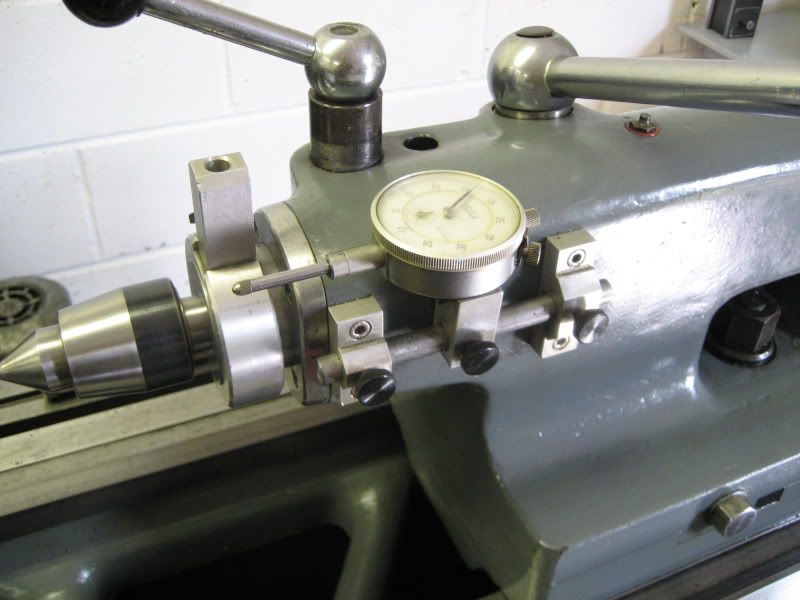

On my vintage DSG 13x42 lathe there is no tailstock depth micrometer. I would like to see how others have adapted their own machine to add a depth mic to the tailstock.

I was surprised when I got the lathe setup that on such a well built machine there was no depth mic on the tailstock, is there a reason they did not put one on? Very handy when drilling to a rough depth etc. Thoughts?

Thanks

Michael

On my vintage DSG 13x42 lathe there is no tailstock depth micrometer. I would like to see how others have adapted their own machine to add a depth mic to the tailstock.

I was surprised when I got the lathe setup that on such a well built machine there was no depth mic on the tailstock, is there a reason they did not put one on? Very handy when drilling to a rough depth etc. Thoughts?

Thanks

Michael