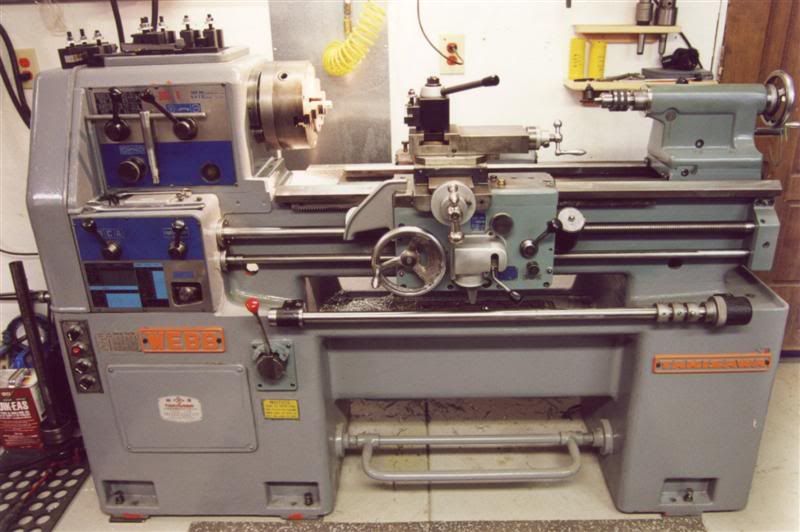

Make: Dong Yang (Korean liscence Okuma)

Model: LS

Year: aprox 1985 Purchased new from close out of dealer in LA.

Swing over bed: 540 mm (21"+)

Swing over cross slide: 14"

Distance between centers: 1500mm (59")

Width across ways(total)15.5"

D1-6 spindle nose with #6 Morse internal taper

Tailstock: 2 speed with rapid move lever, #5 Morse taper, roller bearing lift and slide to move.

Feed Ranges: 64

RPM: 35-1800

Threads: inch 4-56 Metric .5-7mm Module .25-3.5 Dimetral pitch 8-112.

Cross slide tavel: 10.6"

Compound travel: 5.5"

Main Motor: 10 hp. 220/208 3P.

Net weight: 5510#

Came with steady rest, and faceplate.

Tooled up to have: Aloris CXA tool block and assorted tool holders 20+

Heavy duty "tri bearing" Royal #5 morse center. #5 morse Royal CNC style center (extended point)

Jackobs "Ball bearing" drill chuck #16 1/8"-5/8"

Chucks include: Buck 10" 3-jaw. Pratt-Burnerd 10" 6jaw adjust true. 8" Cushman 4-jaw. 12" Willis 4jaw. Jackobs RubberFlex collet setup. Lexair 5-c collet nose closer.

Unusual features: Hydraulic spindle brake. Uses automotive style disc brake on the motor output shaft. Pressure switch drops main contactor when the foot pedal is pushed and the brake is applied. Has very rapid breaking of spindle.

Has unique index system to cut multi lead threads. There are reference marks on the spindle nose and a zero mark on the headstock casting. To cut a multi lead thread you cut the first lead normally. Then rotate the spindle to the zero reference mark, disengage the lead screw using the gearbox levers, rotate the chuck to the mark on the spindle for the number ot leads you are going to cut and re-engage the gearbox lever. Repeat for each lead.

Has very nice tailstock with two methods of moving the quill. Has a handwheel like a normal tailstock. (angled to ease use) Also has a quick acting lever that works like a drill press handle. Can back a drill out of a hole quickly and return and never loose the depth on the handwheel micrometer...very slick.

Tailstock has rollers to ease moving holds tailstock up when not clamped. When clamped rollers are compresed and the base of the tailstock rests fully on the bed.

Has bed mounted trip stops for stopping the power long feed. Mounted to a rail on top of the base, with micrometer adjustment, and quick in /out sliding dogs. (casting)

Has distance collars on the long feed handwheel. Keeps track of number of turns and distance moved (compound collars 2 moving at different rates)

Has compound cross feed micrometer collars that keep track of turns and thousants on diameter..(2 as with the long feed).

Headstock shifts to neutral with lever at top of headstock for ease of dialing up a part...

Cross slide is machined for "T" slots to mount a back tool block or fixturing. Cross slide is fitted with a 3 position turret stop and slide.

Cross feed screw enclosed in oil bath with sight glass.

Fit and finish very good! Not a cheap copy but a nice industrial machine.

Cheers Ross