JDToumanian

Plastic

- Joined

- Sep 6, 2009

- Location

- Phelan, CA

Hello Everyone!

After several years of trying to find a bigger lathe that was in excellent condition, and getting so frustrated by all the time wasted going to look at machines that turned out to be worn out junk that I almost ordered a brand new Hwacheon, I recently bought a 18" Okuma LS lathe.

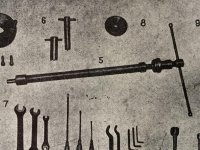

I haven't got it permanently situated and wired up yet because I'm going to insulate, drywall, and air condition my garage, but I did test run it through all the speeds before I bought it... Gears and bearings sound good, good oil flow in the sight glasses. The ways, leadscrews, and nuts are in excellent condition. So, since I've got a bit of downtime with my projects, I'm focusing on tooling up. Manuals and most of the big items were included, but I need a 4-jaw chuck, as well as my focus for this post - the fascinating "center pushout bar" which was included with each lathe as a standard accessory.

As you can read on the attached page from the manual, hammering out centers is strongly discouraged, and it obviously matters enough that they took the care to manufacture and include this special tool... But how many LS owners actually have this item? It seems like something that would get lost because most people would not recognize it as a lathe accessory and it would get left behind even if it was sitting right next to the lathe. How big a deal is it really, to gently tap out something in the spindle taper like my 5C collet adapter? Either way, I suppose this is an accessory I would like to acquire, or I will make one. Perhaps someone got a parts machine and has a spare? Or maybe post up some better pictures than the grainy images from the manual along with some key dimensions?

Thanks for any info. I was surprised in reading all the Okuma posts here that I was unable to find any mention of this interesting tool...

Regards,

Jon

After several years of trying to find a bigger lathe that was in excellent condition, and getting so frustrated by all the time wasted going to look at machines that turned out to be worn out junk that I almost ordered a brand new Hwacheon, I recently bought a 18" Okuma LS lathe.

I haven't got it permanently situated and wired up yet because I'm going to insulate, drywall, and air condition my garage, but I did test run it through all the speeds before I bought it... Gears and bearings sound good, good oil flow in the sight glasses. The ways, leadscrews, and nuts are in excellent condition. So, since I've got a bit of downtime with my projects, I'm focusing on tooling up. Manuals and most of the big items were included, but I need a 4-jaw chuck, as well as my focus for this post - the fascinating "center pushout bar" which was included with each lathe as a standard accessory.

As you can read on the attached page from the manual, hammering out centers is strongly discouraged, and it obviously matters enough that they took the care to manufacture and include this special tool... But how many LS owners actually have this item? It seems like something that would get lost because most people would not recognize it as a lathe accessory and it would get left behind even if it was sitting right next to the lathe. How big a deal is it really, to gently tap out something in the spindle taper like my 5C collet adapter? Either way, I suppose this is an accessory I would like to acquire, or I will make one. Perhaps someone got a parts machine and has a spare? Or maybe post up some better pictures than the grainy images from the manual along with some key dimensions?

Thanks for any info. I was surprised in reading all the Okuma posts here that I was unable to find any mention of this interesting tool...

Regards,

Jon