Gordon B. Clarke

Banned

- Joined

- May 29, 2010

- Location

- Denmark

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

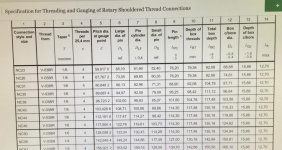

Does anyone know what to do if this was the only information on the drawing re the thread?

View attachment 255778

I can't read the text above the thread but it looks like it may be a feature on the part. Can you speak to the person who made the print?

Did you review this pdf? https://www.api.org/~/media/Files/C...API_7-1_1st-Edition_Addendum-1_March-2007.pdf

(PDF) Specification for Threading and Gauging of Rotary Shouldered Thread Connections | Raphael Ferreira - Academia.edu

You cut to fit Gages.

If you are cutting a Pin the Box Gage has a .625 stand off. If cutting a Box the Pin Gauge is Flush with Face.

What does the part look like? Can your customer supply Gages?

Somebody on PM not so long back invited members to ask him if they had any thread data problems,ask him.

Gordon,

I didn't see this thread soon enough. NC-50 is the same as 4-1/2 IF. IF I recall, I may have sent you the drawing of the details for this thread. API Spec 7-1 does not give all of the information needed to cut the thread if that's what you needed. Anyways, glad you found your answer.

KenS.

This will not help any, just an odd story. I worked in a shop that threaded drill stem joints for a couple of years. Every now and then then the shop would have to make a new thread size. The drill was the foreman would come out with a hardened and ground go gauge and make a pair of gauges from whatever material was on hand usually 4140. I never saw the original gauge again, whether it was rented and sent back or just stored in the locked room with the shop made gauges I do not know. The time I was there I do not remember ever being allowed in that room. Can't say that I ever saw into the room from the doorway. These shop made gauges were cut with hand ground braised carbide tools. The grinder had a silicon carbide wheel with just a plain tool rest. All the tool joints we made would be gauged with these shop made gauges. Never saw one replaced at the time I assumed the originals were still in that room but thinking about it they were probably so expensive they were just rented.

Notice

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.