How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

coolest stuff to come out of your shop

- Thread starter Sam L

- Start date

- Replies 63

- Views 24,840

It's not cool unless it actually blows up, otherwise its just a cone shape piece of metal

I can't think of what was the most fun or interesting thing I made so far, they're just parts I guess. Some of it does go into pretty neat pieces of equipment that would definitely fit the super cool category, but as individual parts they're pretty boring no matter how complex and time consuming.

I can't think of what was the most fun or interesting thing I made so far, they're just parts I guess. Some of it does go into pretty neat pieces of equipment that would definitely fit the super cool category, but as individual parts they're pretty boring no matter how complex and time consuming.

proturn

Stainless

- Joined

- Jan 20, 2010

- Location

- zimmerman, mn.usa

6061 Billet International 300/400 front covers for pulling tractors

http://www.tpemachine.comI just made these a few weeks ago. They started out 87 lbs and after all the machining they were 12.5lbs.

http://www.tpemachine.comI just made these a few weeks ago. They started out 87 lbs and after all the machining they were 12.5lbs.

MK Proto

Hot Rolled

- Joined

- Mar 7, 2011

- Location

- Bensalem, PA

reedeprintice

Stainless

- Joined

- Feb 22, 2008

- Location

- Paradise , California

reedeprintice

Stainless

- Joined

- Feb 22, 2008

- Location

- Paradise , California

reedeprintice

Stainless

- Joined

- Feb 22, 2008

- Location

- Paradise , California

mroy0404

Cast Iron

- Joined

- Mar 13, 2005

- Location

- Sarnia Ont. Canada

Cool stuff from my shop

smallshop

Diamond

- Joined

- Jun 2, 2005

- Location

- North Central Montana

hey...show us one with the cover over the blades! Very clean looking btw.

Bobw

Diamond

- Joined

- Feb 8, 2005

- Location

- Hatch, NM Chile capital of the WORLD

This toilet flushes really hard. I could keep replacing handles, fix the problem, or just make a bigger and better flusher.

17-4, 7/16" 17-4 shaft and the rod going to the chain is 1/2x3/16 304.

I need to finish polishing it, and the little lady wants the kokopelli filled in with turquoise.

17-4, 7/16" 17-4 shaft and the rod going to the chain is 1/2x3/16 304.

I need to finish polishing it, and the little lady wants the kokopelli filled in with turquoise.

lectrician1

Hot Rolled

- Joined

- Mar 6, 2012

- Location

- Las Vegas

mroy0404

Cast Iron

- Joined

- Mar 13, 2005

- Location

- Sarnia Ont. Canada

hey...show us one with the cover over the blades! Very clean looking btw.

Here are afew more pic's of the 61" Dia. wind turbine Hub and Nose cone.

JH-Q

Aluminum

- Joined

- Mar 17, 2008

- Location

- Tampere, Finland

Here's a 23" dia six groove flat belt pulley i made.

The blank came to my shop as shown in first picture, some other shop had roughed it from a 600kg solid by feed milling.

When it came to me it was around 250kg. Finished weight was 150kg.

I had to turn the internal tapers by feeding compound slide by hand, because the tapers were too steep for taper turning attachment and the compound doesn't have feed in it. The outer taper has a 6mm radius in the corner, so i had to grind some HSS to make it.

Also the smallest ID had a tolerance of -0 +0.06mm.

Fun little part to make.

The blank came to my shop as shown in first picture, some other shop had roughed it from a 600kg solid by feed milling.

When it came to me it was around 250kg. Finished weight was 150kg.

I had to turn the internal tapers by feeding compound slide by hand, because the tapers were too steep for taper turning attachment and the compound doesn't have feed in it. The outer taper has a 6mm radius in the corner, so i had to grind some HSS to make it.

Also the smallest ID had a tolerance of -0 +0.06mm.

Fun little part to make.

Fear Factory

Aluminum

- Joined

- May 22, 2011

- Location

- Australia, Victoria

How Does one hold that Piece In the first image, that's super thin... Actually Inspiring I am going to chuck up a beer can in the lathe and try to put some grooves in it let you know how it goes.

rj newbould

Diamond

- Joined

- Aug 29, 2005

- Location

- Hernando, FL

That is probably best held on a vacuum chuck.How Does one hold that Piece In the first image, that's super thin... Actually Inspiring I am going to chuck up a beer can in the lathe and try to put some grooves in it let you know how it goes.

Nick Mueller

Titanium

- Joined

- Jun 12, 2006

- Location

- Munich / Germany

Not the final product, it lacks a few details:

A test who scraping in scale 1:10 would look like.

What you see here is aluminium cast in sand.

I'll spin cast the hand wheels etc. in pewter.

I made the patterns for a casting demonstration. And I didn't want to have something to cast that would be thrown away at the same day.

Nick

A test who scraping in scale 1:10 would look like.

What you see here is aluminium cast in sand.

I'll spin cast the hand wheels etc. in pewter.

I made the patterns for a casting demonstration. And I didn't want to have something to cast that would be thrown away at the same day.

Nick

scadvice

Titanium

- Joined

- Jan 16, 2009

- Location

- "Stuck in Lodi", Ca

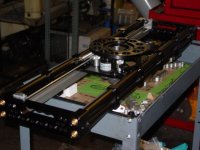

Here is an example.

We built this mandrel for UC Davis here in California. We made it on our little Fadal VMC15XT ( the one I did the forum on... http://www.practicalmachinist.com/v...er-issues/my-seven-year-fadal-rebuild-213008/ ) It was moved three times to machine the full length. Here's the link to the CMM inspection and a short video of it done in the Fermi National Laboratory.

CMS Trigger Tracker : Mandrel CMM Data

Wish I could post some other stuff we do, but like a lot of you out there, we too are constrained under nondisclosure agreements.

I'll dig up some other stuff when I get time that I can show.

Steve

We built this mandrel for UC Davis here in California. We made it on our little Fadal VMC15XT ( the one I did the forum on... http://www.practicalmachinist.com/v...er-issues/my-seven-year-fadal-rebuild-213008/ ) It was moved three times to machine the full length. Here's the link to the CMM inspection and a short video of it done in the Fermi National Laboratory.

CMS Trigger Tracker : Mandrel CMM Data

Wish I could post some other stuff we do, but like a lot of you out there, we too are constrained under nondisclosure agreements.

I'll dig up some other stuff when I get time that I can show.

Steve

Last edited:

MK Proto

Hot Rolled

- Joined

- Mar 7, 2011

- Location

- Bensalem, PA

That Part is 4 operations, Rough Rough, finish, then finish in a vacuum fixture, similar to the part in the front of the second picture only smaller.

SIM

Titanium

- Joined

- Feb 19, 2004

- Location

- Staten Island NewYork USA

Similar threads

- Replies

- 42

- Views

- 1K

- Replies

- 45

- Views

- 3K

- Replies

- 12

- Views

- 961