Hello all,

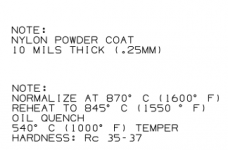

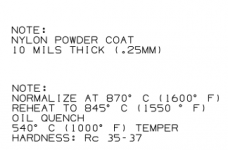

My question is about some parts that a costumer requested we do. In the past we've done mainly steel and aluminum. However, one of our preferred customers is expanding into some non traditional material and processes. For example AMPCO 18, 4140 annealed steel, A2 tool steel. Processes include coatings such as Nylon powder coat 10 mils thick, and Zinc chromate coatings on the amp-co parts.

I've done some home work; i have handle on the material cost. My main question here is how to mark up my quote to accommodate the different material. For example, say we have a block made out 1060 that we would charge $100.00 for. Now we have a very familiar block made out of a2 TOOL STEEL OR AMPCO 18. The material is $10.00 more, but how much do i quote for the increased time it takes to machine tougher material. I've heard A2 is similar to stainless, i'm in the dark on Ampco. I want to have a decent initial starting point and not lose my ass until i have real data. If anyone has experience with this i'd love some insight.

With the coatings i guess mainly i'd love a reference. The couple of places near buy i got a quote from said price for the coating is per/lb roughly 75-100 minimum, and that covers the first 20 lbs. Is this the going rate or is the 2 guys near me just off? Also we're doing mall batch part 1-8 pcs.

If i have this $100 block add i only need to make 2 of them.i add 10 for material matl. mark up my machine time 15% for A2 cutting slower than 1060 , and add $100 for coating both blocks. My new price is $174.25 per block. It seems crazy to me, am i way off base here of does this seem close?

My question is about some parts that a costumer requested we do. In the past we've done mainly steel and aluminum. However, one of our preferred customers is expanding into some non traditional material and processes. For example AMPCO 18, 4140 annealed steel, A2 tool steel. Processes include coatings such as Nylon powder coat 10 mils thick, and Zinc chromate coatings on the amp-co parts.

I've done some home work; i have handle on the material cost. My main question here is how to mark up my quote to accommodate the different material. For example, say we have a block made out 1060 that we would charge $100.00 for. Now we have a very familiar block made out of a2 TOOL STEEL OR AMPCO 18. The material is $10.00 more, but how much do i quote for the increased time it takes to machine tougher material. I've heard A2 is similar to stainless, i'm in the dark on Ampco. I want to have a decent initial starting point and not lose my ass until i have real data. If anyone has experience with this i'd love some insight.

With the coatings i guess mainly i'd love a reference. The couple of places near buy i got a quote from said price for the coating is per/lb roughly 75-100 minimum, and that covers the first 20 lbs. Is this the going rate or is the 2 guys near me just off? Also we're doing mall batch part 1-8 pcs.

If i have this $100 block add i only need to make 2 of them.i add 10 for material matl. mark up my machine time 15% for A2 cutting slower than 1060 , and add $100 for coating both blocks. My new price is $174.25 per block. It seems crazy to me, am i way off base here of does this seem close?