snowman

Diamond

- Joined

- Jul 31, 2004

- Location

- Southeast Michigan

Don,

What kind of quantity did you used to sell, monthly or yearly.

-Jacob

What kind of quantity did you used to sell, monthly or yearly.

-Jacob

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

First off I'm not sure what you mean by 'one at a time' since of course one wouldn't sub any small part out "just one"...I recall getting hundreds of some parts "at a time"...depends on the part and how many of that part were used in each machine. Also, in my case, certain volumes were needed to make black oxide and annodizing in batches cost effective.

First off I'm not sure what you mean by 'one at a time' since of course one wouldn't sub any small part out "just one"...I recall getting hundreds of some parts "at a time"...depends on the part and how many of that part were used in each machine. Also, in my case, certain volumes were needed to make black oxide and annodizing in batches cost effective.

Imagine that, the younger guys asking the big D for business advice!!

Imagine that, the younger guys asking the big D for business advice!!  Don, they are asking because you have "been there, done that, got the t-shirt" (Or in the case, got the greenbacks)

Don, they are asking because you have "been there, done that, got the t-shirt" (Or in the case, got the greenbacks) That has a 10yr limit, right?Well there is that pesky "covenant not to compete" I had to sign

I was joking on the 50 year number.Oh come on now, no way discussing inventory management, a generic concept, is covered by a non-compete agreement.

I thought that so obvious that it would be obvious I was just joking around with dk after he mentioned something equally "whimsical" to the situation.Oh come on now, no way discussing inventory management, a generic concept, is covered by a non-compete agreement.

Yep. I was constantly tinkering with design improvments and new accessories, so, for my situation, the major "how many to order" cringer was not that sales would slow, but that I might want to change the design of some aspect of the product, which would make some of those parts instantly obsolete and worthless.because each market is individual, and each person approaches a problem differently....

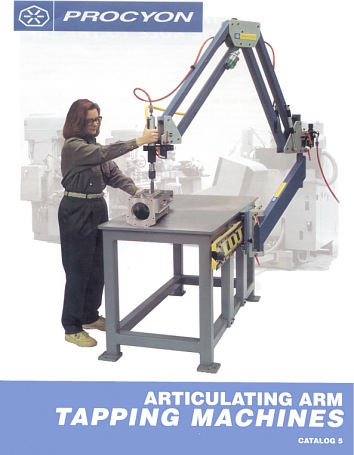

There is a tremendous strain at main pivot point with the arm all the way out, tapping 1" NC taps. Plus the unit was meant to have the possiblity of tapping castings sitting on the floor behind the table...in which case a heavy table was needed for counterweight as well.Don, you certainly didn’t build your tapping tables based on the results of a stress analyses computation did you? You talk about over kill,

Notice

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.