I need a lifting aid solution for our VMC. It will be used for loading and unloading production parts...and also for set-up...lifting vices and fixtures..etc.

I've struggled with this in the past as it just seems to be cumbersome and slow to use a hoist or crane.

Our parts might weight upto about 50 lbs....and I no longer want our employees lifting this much repetatively.

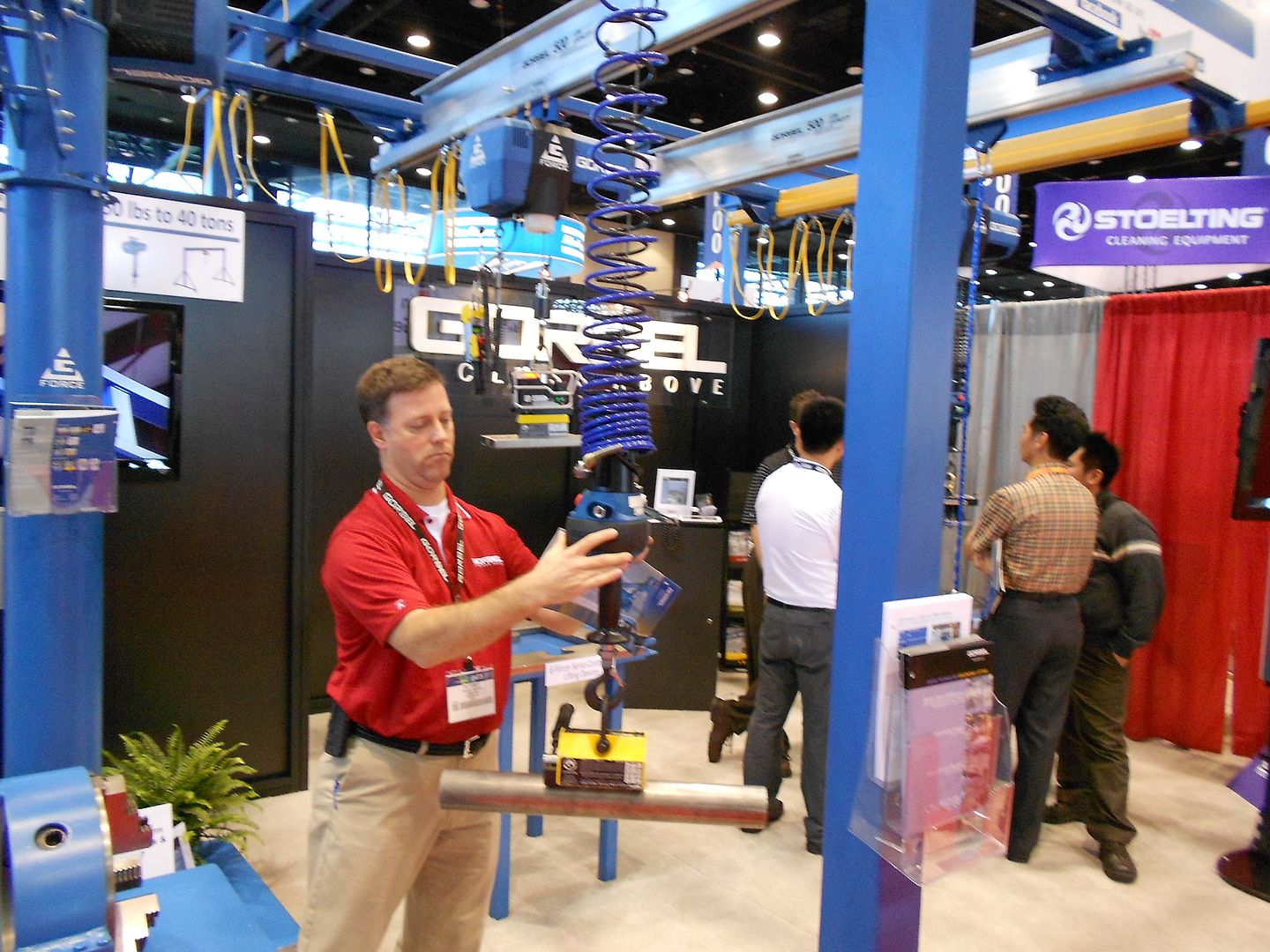

My thought is that maybe a small jib crane will do the job:

Thoughts? What do you use?

Thanks!

-R

I've struggled with this in the past as it just seems to be cumbersome and slow to use a hoist or crane.

Our parts might weight upto about 50 lbs....and I no longer want our employees lifting this much repetatively.

My thought is that maybe a small jib crane will do the job:

Thoughts? What do you use?

Thanks!

-R