Yuhknow.... I was looking at a 3 story building a cpl yrs ago that needed a new rubber roof, to the tune of around $35G was the estimate that the realtor told me. And they said that they would look into just puting a regular pitched roof on it if $pending that much....

But I considered that - and what I came away with was that ice (cicles) will be falling a long way, and be terribly dangerous.

Not that there should be anyone there to speak of. (not a city sidewalk type app)

But then I look around since, and now I notice that there are oodles of pitched roofs that are in way worse locations than I was looking at.

Makes one think that maybe a fella needs to put a hard hat on to walk down some sidewalks in late February/March?

Kind'a like the concept that I need to put my safety glasses on when I walk outside in the summer, way more than I need them indoors.

The dag'um Kamikaze bugs that read just a wee bit too much into that "Wait 'till you see the whites of their eye's" statement.

--------------

Speaking of Ice

Ox

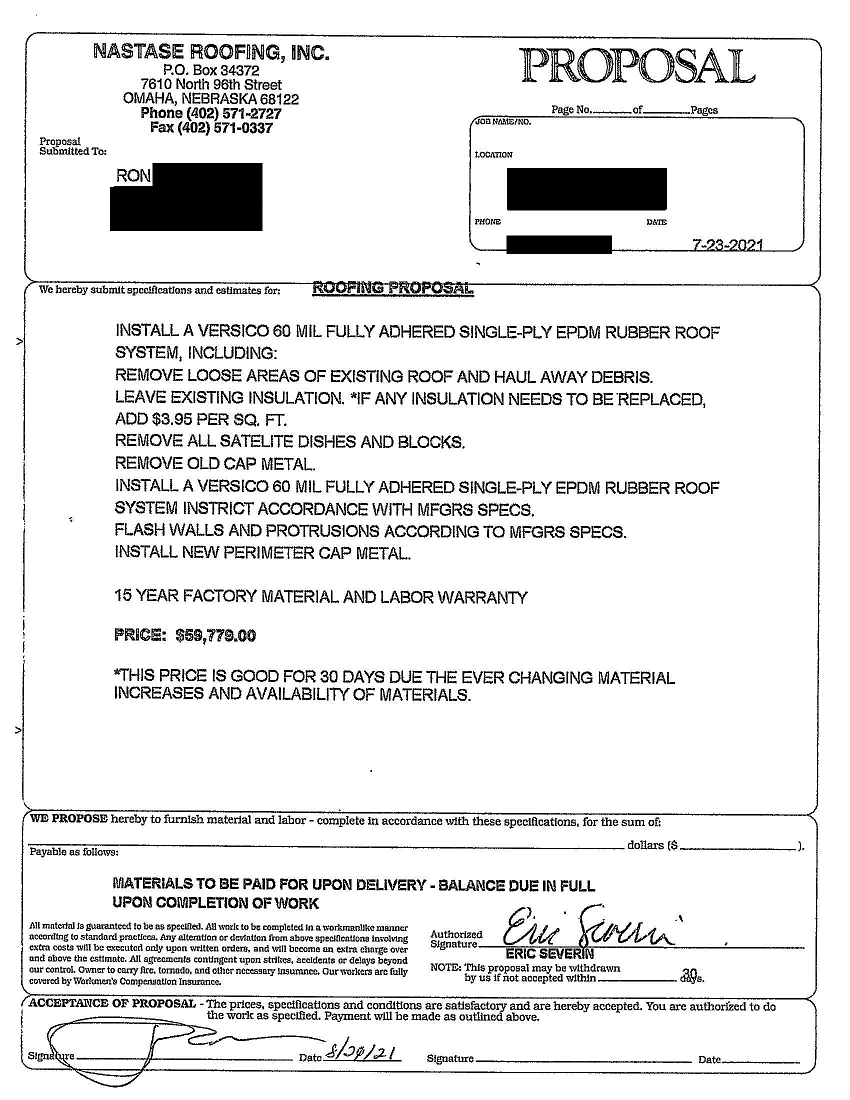

Hopefully that number makes a lot more sense.

Hopefully that number makes a lot more sense.