rfhebbler

Plastic

- Joined

- May 30, 2007

- Location

- Baton Rouge, LA

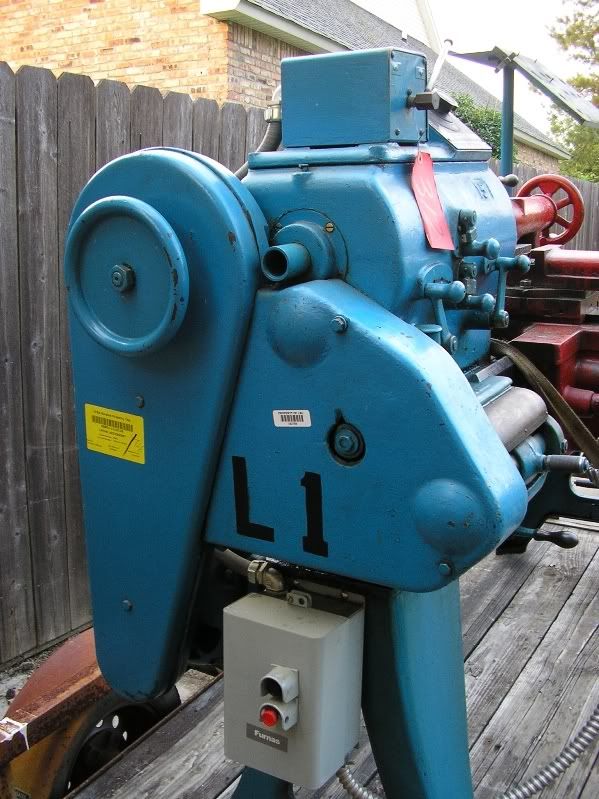

I just picked up a LeBlond 15" 36"center lathe from a state auction. The lathe came from L.S.U. and according to LeBond LTD it was delivered to them Sept. 1941. I was inquiring about chucks and was told it had 2 1/8" 5tpi threading and I would not likely find a chuck. He said many chose options using backplates and flat back chucks. I'm new to this game and would like some feedback and advice from you gurus. Are chucks and steady rests availble for these? I tried Ebay but didn't get any hits. Any help would be appreciated.

Ray

Ray