Hi Dave,

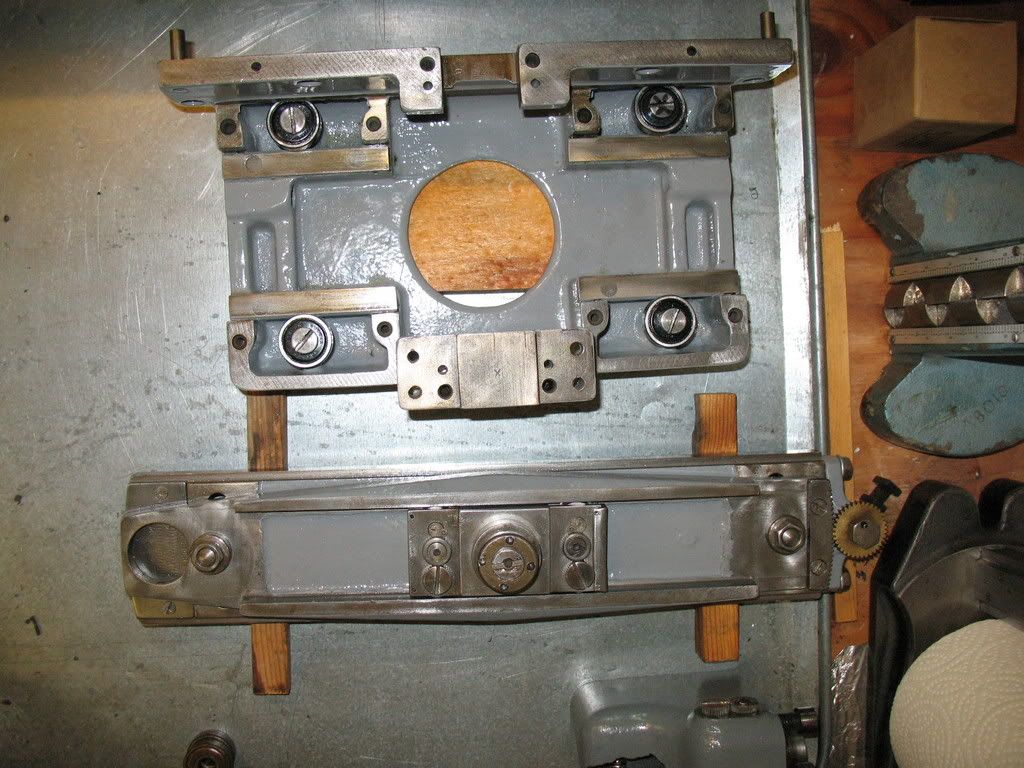

Your taper attachment looks pretty complete, with the exception of the bed clamp already mentioned. My machine is missing both the bed clamp and the draw-rod. The draw-rod unscrews from the bottom of the T/A and is normally stored when not in use.

What is the broken casting sticking out from under the T/A, right above the 'j' in "Adjustment"? I don't recognize that as being part of the machine.

You will want to take the T/A apart and service it before you try to use it. There is no automatic lubrication for the T/A, so it needs to be taken apart and wiped down with Vactra #2 way lube every 12 months or so; much more frequently if you use coolant. There are pockets in the base casting (under each of the large bearings, in the top of my first photo) that can collect water or coolant and destroy the bearings; some folks have drilled drain holes to mitigate this. The drawbar (as opposed to the draw-rod, on top of the cross slide screw), slide, swivel and shoe, as well as the shoe stud and swivel stud, should be cleaned and lubricated. It's a good idea to clean and lube the cross slide and compound screws on the same schedule.

Cal