Hello - I am confounded as to how the forward,neutral, reverse selector is removed from the headstock. I've pulled the handle, but can't seem to get the round dome shaped piece off (I'd like to powdercoat a few of these small pieces at work).

Anybody know how to do this? The drawing from Monarch shows that there are 3 flat screws (if I am looking at the correct drawing), but I have removed the paint and can find no such screws.

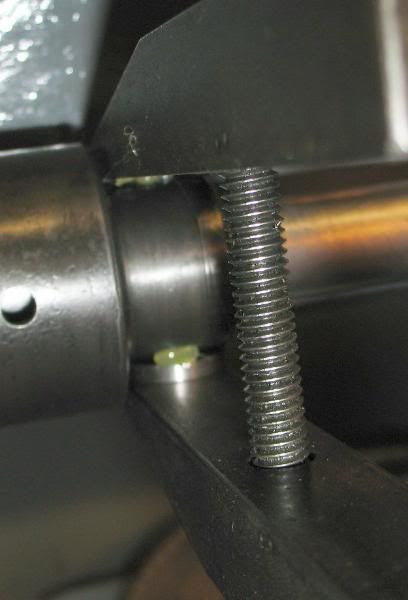

Also, I have a selector switch on the face of the lathe that has a taper pin in it, which I can't seem to knock loose - are there any secret methods (are well known for that matter) for removing taper pins other than a punch?

Anybody know how to do this? The drawing from Monarch shows that there are 3 flat screws (if I am looking at the correct drawing), but I have removed the paint and can find no such screws.

Also, I have a selector switch on the face of the lathe that has a taper pin in it, which I can't seem to knock loose - are there any secret methods (are well known for that matter) for removing taper pins other than a punch?