mgberry

Aluminum

- Joined

- Jan 18, 2012

- Location

- Raleigh, NC

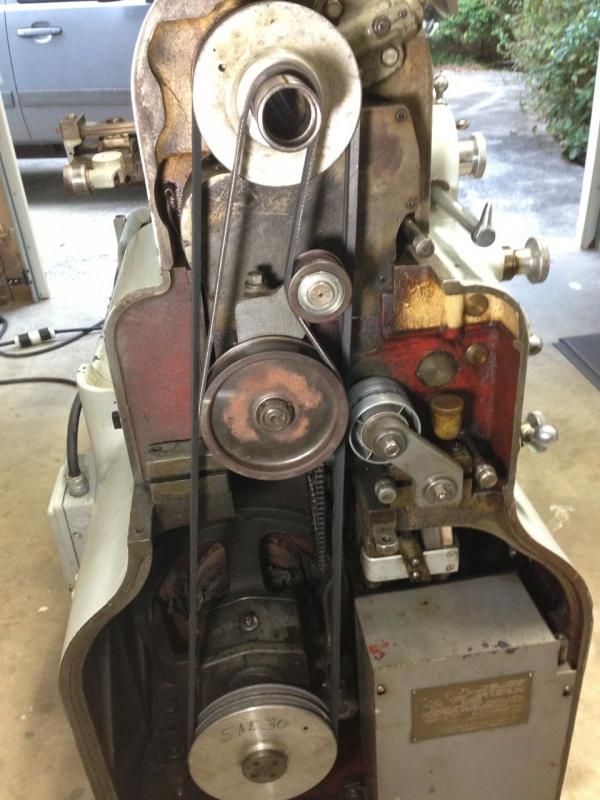

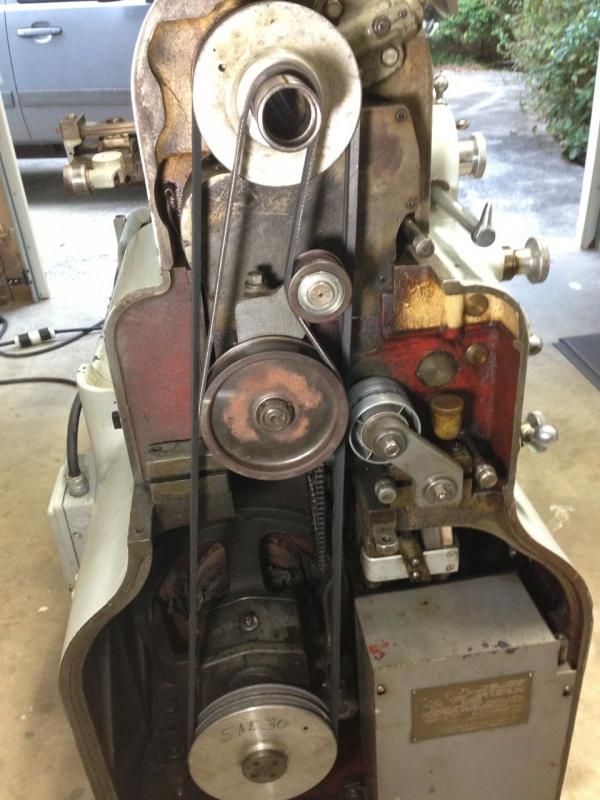

This has been beaten to death, but I could not make heads or tails. I needed to replace my belts on my '51 square dial MG (Reliance large frame) and what was on there was A85 (XB) belts. I ordered up a set of Goodyear A85 HY-T Matchmakers as the replacement. I immediately notice that the new belts were much tighter, but I could get them on without raising the motor. Doing so takes quite a bit of arm to roll it up over the spindle pulley. The belts are so tight that I am unable to install the left side idler (you can see it missing in the pic) because the belt wont budge more than a 1/2 inch or so.

If I run it as is, should I be concerned w the tension being to tight and putting excess load on the spindle bearings?

I tried to raise motor some, but when doing so it created a gab between the rubber and the motor plate and this didnt seem to feel right. I am thinking about test fitting another size, but was looking for feedback first.

[/URL]

[/URL]

If I run it as is, should I be concerned w the tension being to tight and putting excess load on the spindle bearings?

I tried to raise motor some, but when doing so it created a gab between the rubber and the motor plate and this didnt seem to feel right. I am thinking about test fitting another size, but was looking for feedback first.