mandmj

Plastic

- Joined

- Mar 22, 2018

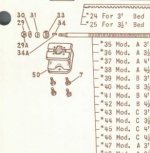

Hello, I have fairly recently acquired a 10k (first lathe) that while filthy, overall appears in good to very good condition. The worst problem I've found so far is that before I began disassembly and rehab was the lead screw had a lot of longitudinal play/slop, nearing a quarter of an inch. The leadscrew gear took some damage due to this, but I've cleaned up the teeth somewhat and removed the largest burrs. However, the leadscrew itself looks very good as do the half nuts, but I noted a loose locknut in the gearbox on the end of the leadscrew. I'm finally beginning reassembly of the lathe now, and I put a new locknut on the leadscrew tonight, and noted that while the play was dramatically reduced, it was still quite a lot and I was able to get about 0.075" feeler gauges into the gap between the leadscrew shoulder and the gearbox casing (externally). There were no shims/washers present on this area at disassembly. It looks to me that the leadscrew needs to be shimmed between the casing and shoulder (outside the gearbox) for proper alignment of the gears in the box (see pics). I've ordered some round shim stock (steel) to adjust this, but wanted to make sure I was on the right path to fixing this issue, and what amount of play would be considered appropriate?

Thanks for the help.

Thanks for the help.