How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

10L tail stock spindle guide pin removal - How To?

- Thread starter Bill Pace

- Start date

- Replies 7

- Views 3,423

aromakr

Plastic

- Joined

- May 11, 2011

- Location

- Montana USA

I was going to post the same question, hope someone can help.

bradjacob

Titanium

- Joined

- Nov 18, 2008

- Location

- Easton, PA

Good question. I'd bet money that it's a pressed-in part.

Ted or Turk would be the one's I'd reach out to?

Ted or Turk would be the one's I'd reach out to?

As you may have noticed my question was posted several days back - so not having any info I just went at it with a closer observation and pretty quickly discovered the answer.

Underneath the exposed pin on the outside at the curve of the cast housing - very nearly hidden - is the other end of the pin, and could quickly tell that it was at an angle. It was so well blended into the casting, I first thought SB may have sealed it in with babbit, but a touch with a drill bit proved to not be the case and that the pin wasnt hardened. So I got a punch and gave it a few mild whacks, it quickly started to move and soon popped out. Turned out is is a conventional 5/16" piece of round, with the pin profile ground in, sitting at a 45° in the housing. My pins tip was worn to about .170 from its original 3/16" and the spindle groove seemed to be around .192 -.195, combining to give quite a bit of slop in the spindle.

I got about an 8" piece 5/16" drill rod, set it in the vice at 45°. and milled the 3/16" wide tip and drove it in -- but the spindle wouldnt slide freely the full travel. After tinkering around with the width of the tip, it became apparent that that wasnt gonna work... so I took the spindle and milled a new slot at 7/32" and re cut a new tip at about .210-.212, for some clearance in the .219 groove. Put the new pin back in and - voila! - really nicely fitting and smooth spindle all the way thru its range.

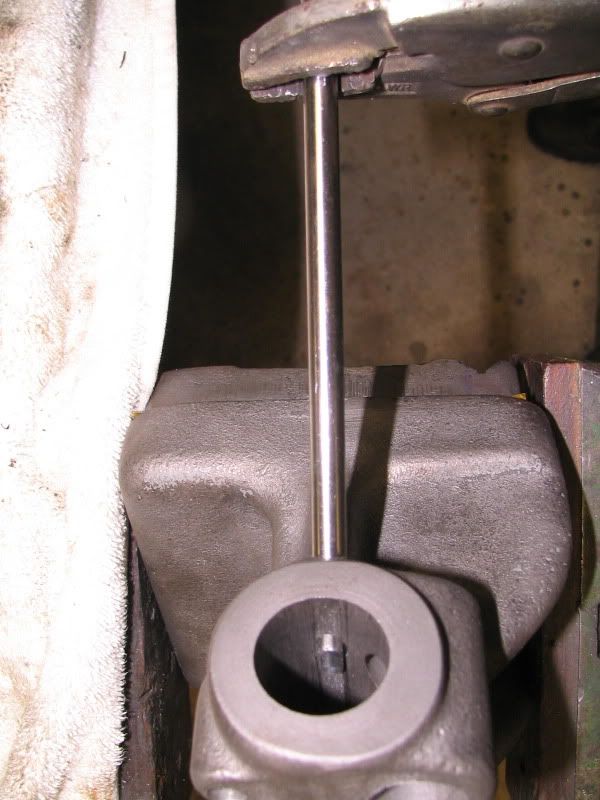

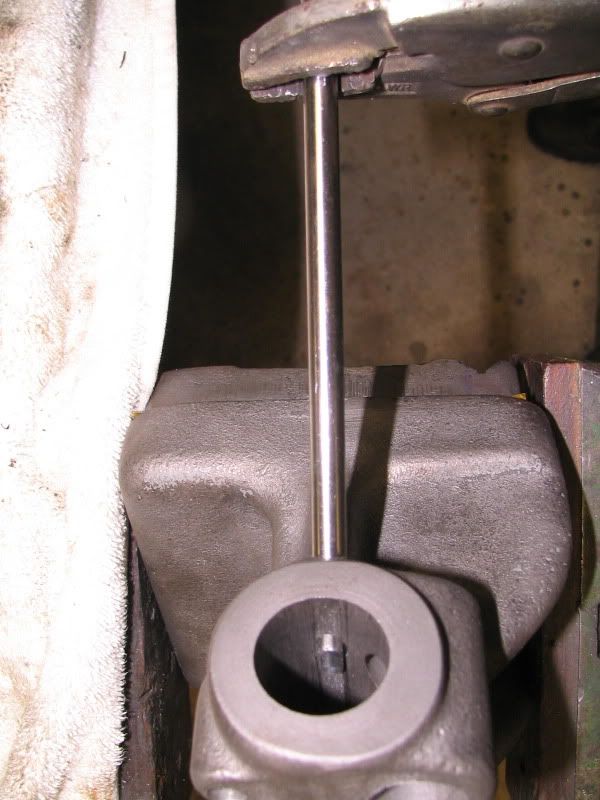

Heres the original pin freshly out of its home and then the new pin with vise grips locked on to position the pin in the slot. After getting it in place I used a die grinder and cutting disc to cut it off and smooth it back flush with the casting -- all in all a very satisfying project

Underneath the exposed pin on the outside at the curve of the cast housing - very nearly hidden - is the other end of the pin, and could quickly tell that it was at an angle. It was so well blended into the casting, I first thought SB may have sealed it in with babbit, but a touch with a drill bit proved to not be the case and that the pin wasnt hardened. So I got a punch and gave it a few mild whacks, it quickly started to move and soon popped out. Turned out is is a conventional 5/16" piece of round, with the pin profile ground in, sitting at a 45° in the housing. My pins tip was worn to about .170 from its original 3/16" and the spindle groove seemed to be around .192 -.195, combining to give quite a bit of slop in the spindle.

I got about an 8" piece 5/16" drill rod, set it in the vice at 45°. and milled the 3/16" wide tip and drove it in -- but the spindle wouldnt slide freely the full travel. After tinkering around with the width of the tip, it became apparent that that wasnt gonna work... so I took the spindle and milled a new slot at 7/32" and re cut a new tip at about .210-.212, for some clearance in the .219 groove. Put the new pin back in and - voila! - really nicely fitting and smooth spindle all the way thru its range.

Heres the original pin freshly out of its home and then the new pin with vise grips locked on to position the pin in the slot. After getting it in place I used a die grinder and cutting disc to cut it off and smooth it back flush with the casting -- all in all a very satisfying project

iwananew10K

Diamond

- Joined

- Sep 12, 2010

- Location

- moscow,ohio

you`re gonna have one heck of a nice 10L soon, you`re kicking it`s lazy ass into complete submission!

you`re gonna have one heck of a nice 10L soon, you`re kicking it`s lazy ass into complete submission!

Yes, its in its final death throes .... and quite a battle it has been. Looking back to May when I got it, if I had known how bad it was --- well, I wonder what I would have done.

But, yes, it should be a nice 60 year old 10L. I've got to find it a new home in the shop somewhere and get it off the furniture casters and on the floor and leveled all nice --- and make some chips!! Hopefully in the next couple weeks...

JimFL

Plastic

- Joined

- Aug 16, 2011

- Location

- Tampa Bay, FL

Nice job. I just did mine this afternoon, too. I have a 13" and the size is 7/16" rather than 5/16". I also noticed mine has a slotted setscrew in the back just under the spindle clamp. Loosening that, I just pushed the pin out of the housing. It made for an easy install, also. No hammering on it!

mokusbajusz

Aluminum

- Joined

- Jul 25, 2010

- Location

- Budapest, Hungary

I also noticed mine has a slotted setscrew in the back just under the spindle clamp. Loosening that, I just pushed the pin out of the housing. It made for an easy install, also. No hammering on it!

That sounds like a mod worth to do for the restorers having a 9" ...

Bill,

nice, clean job, congrats!

Similar threads

- Replies

- 12

- Views

- 529

- Replies

- 19

- Views

- 917

- Replies

- 13

- Views

- 1K

- Replies

- 10

- Views

- 556