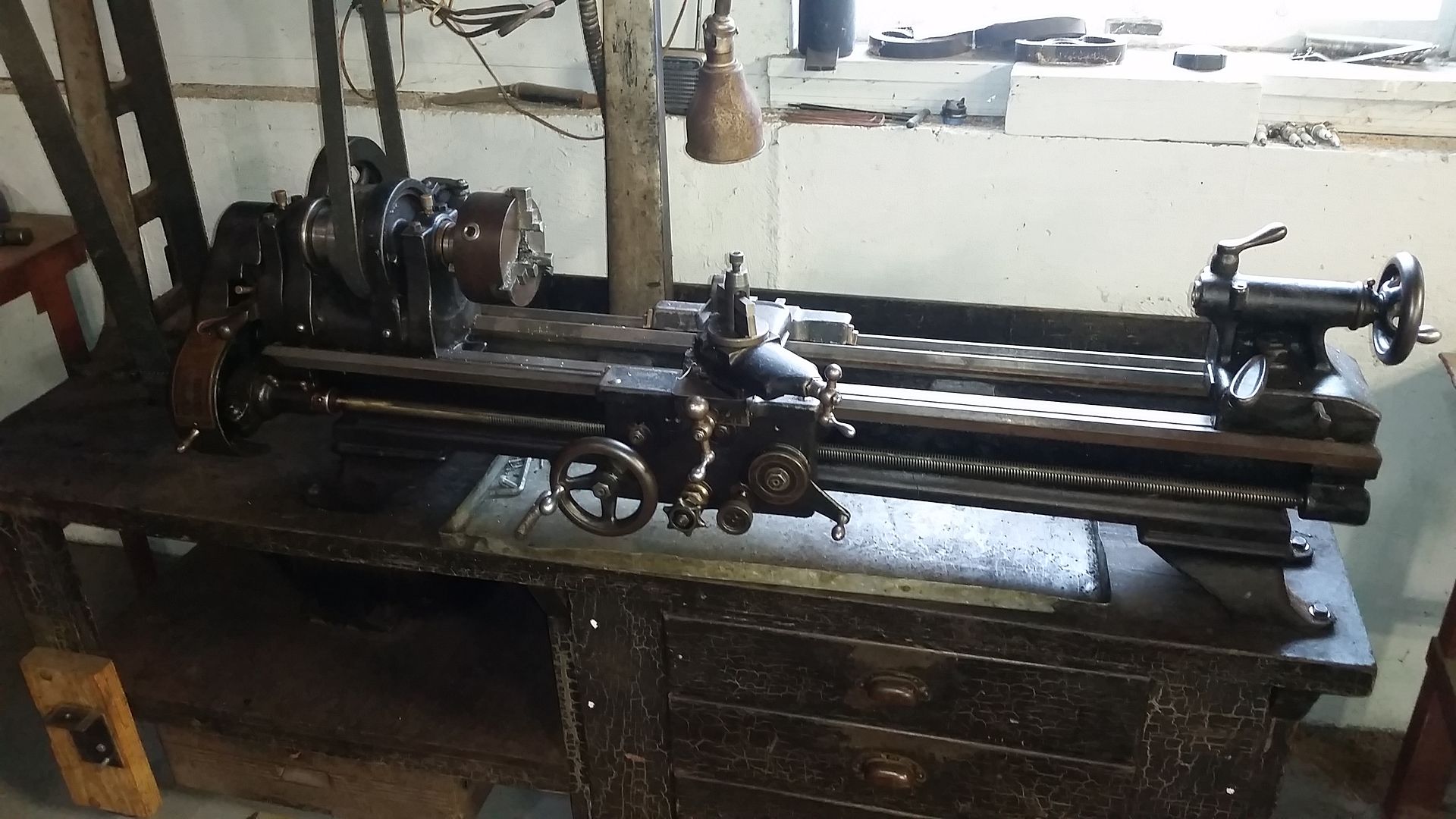

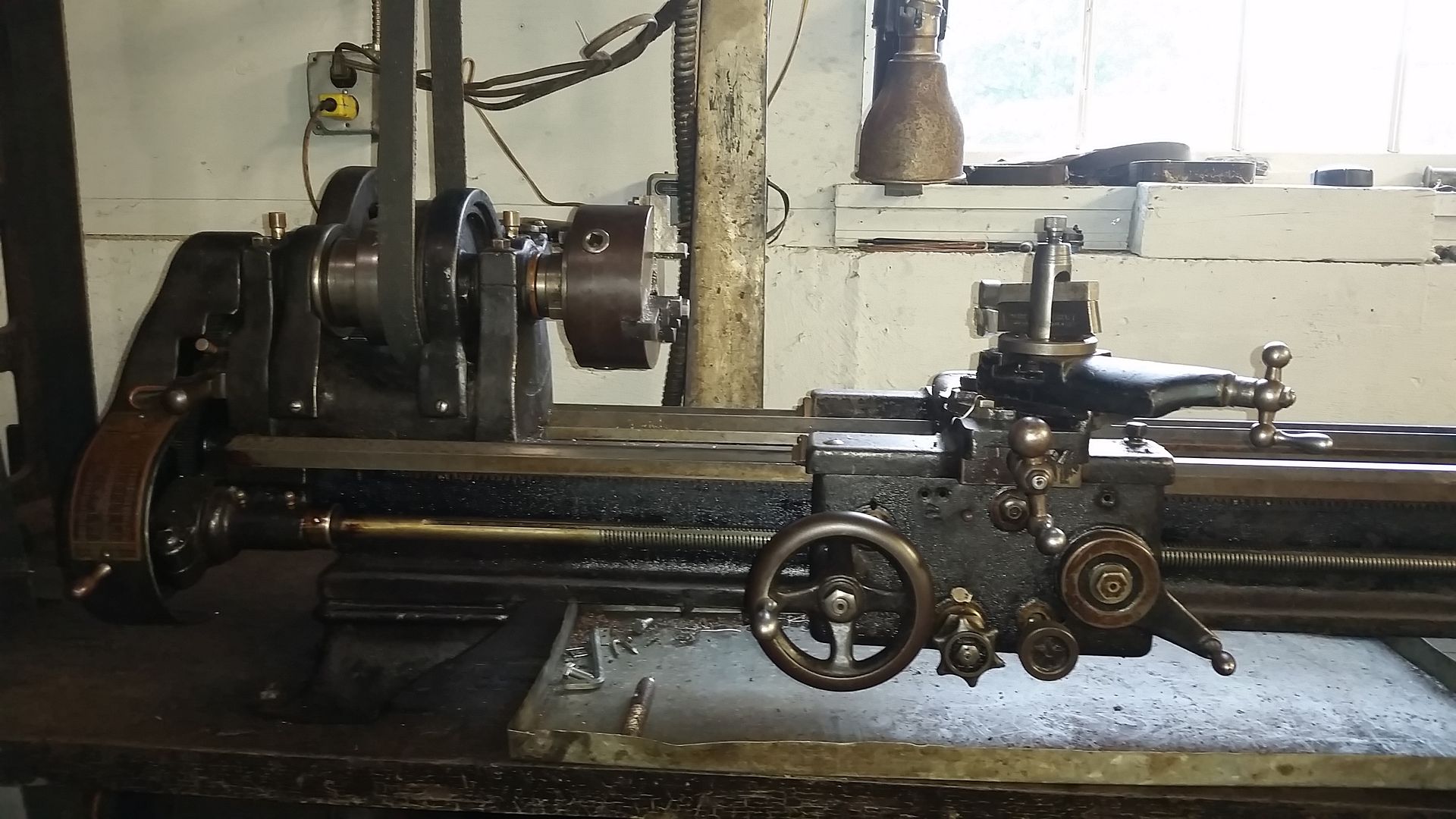

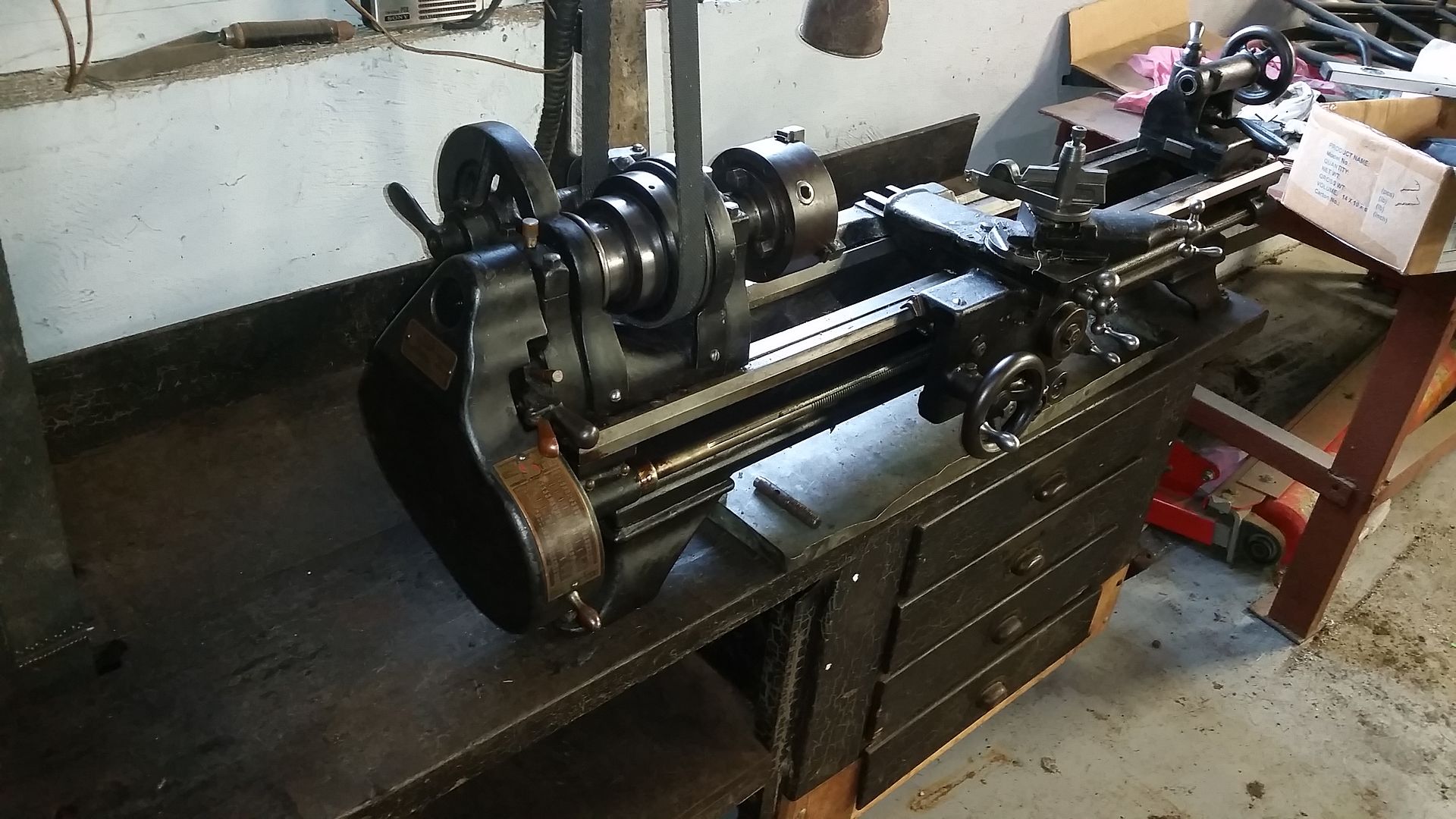

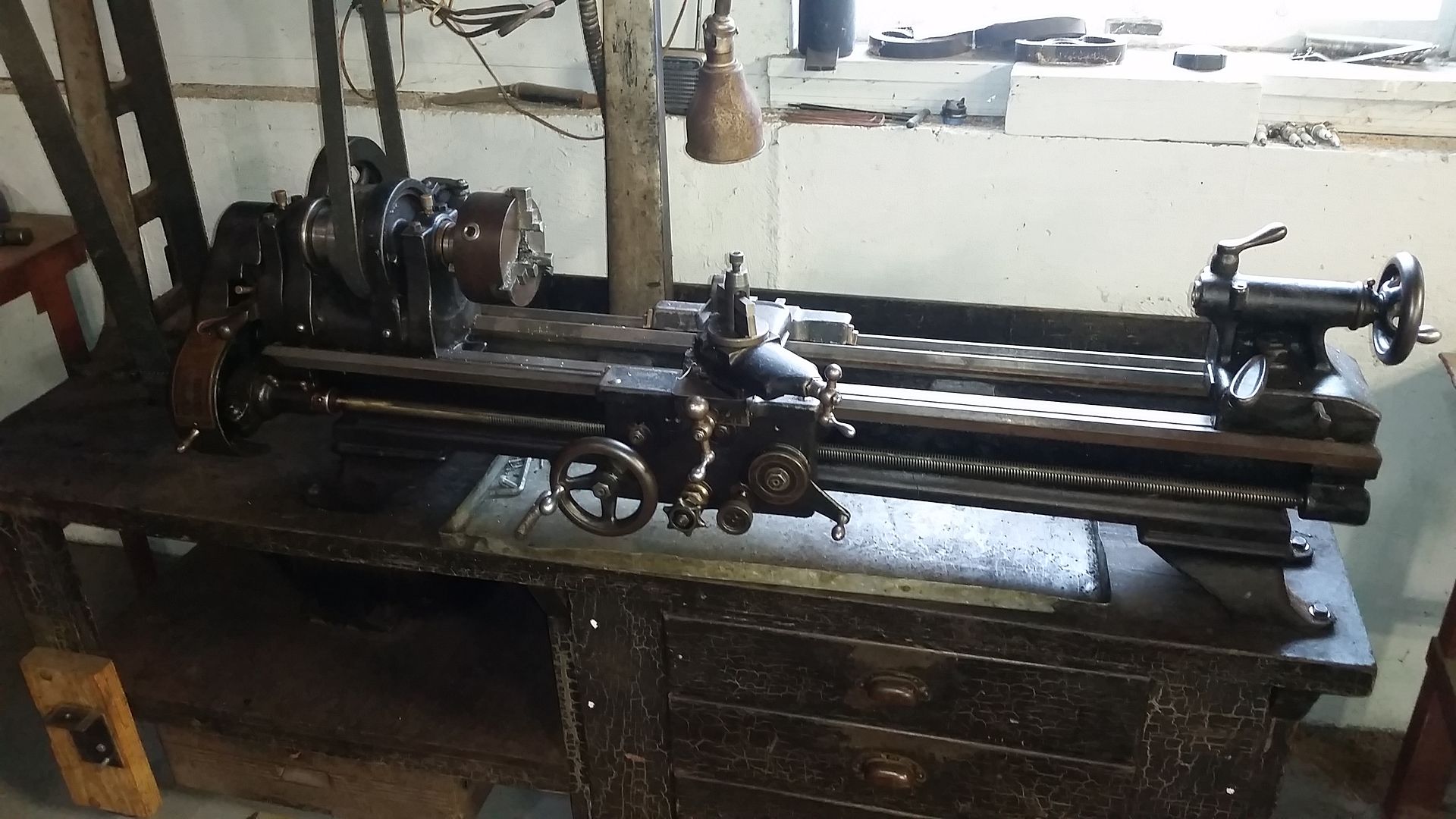

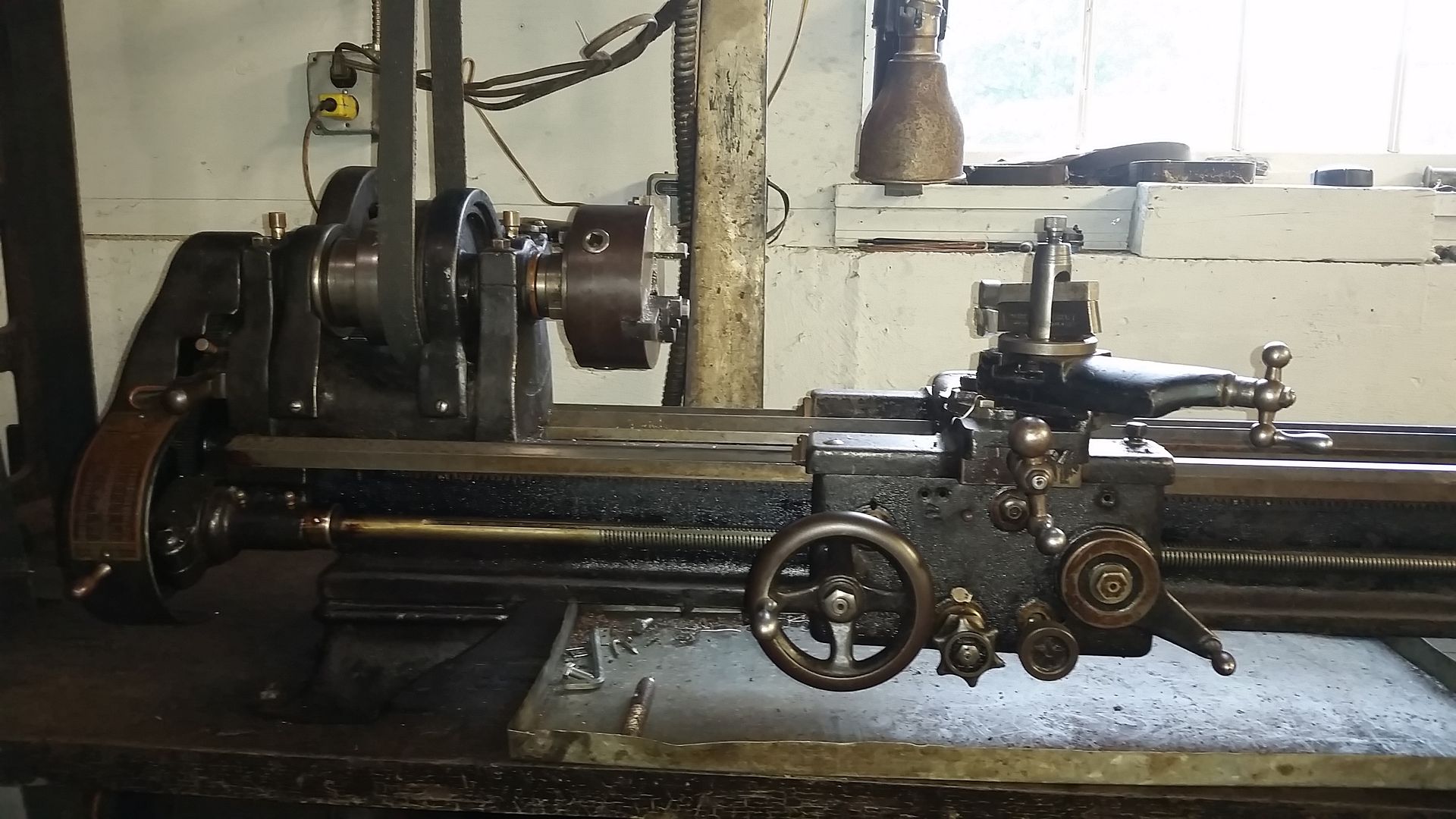

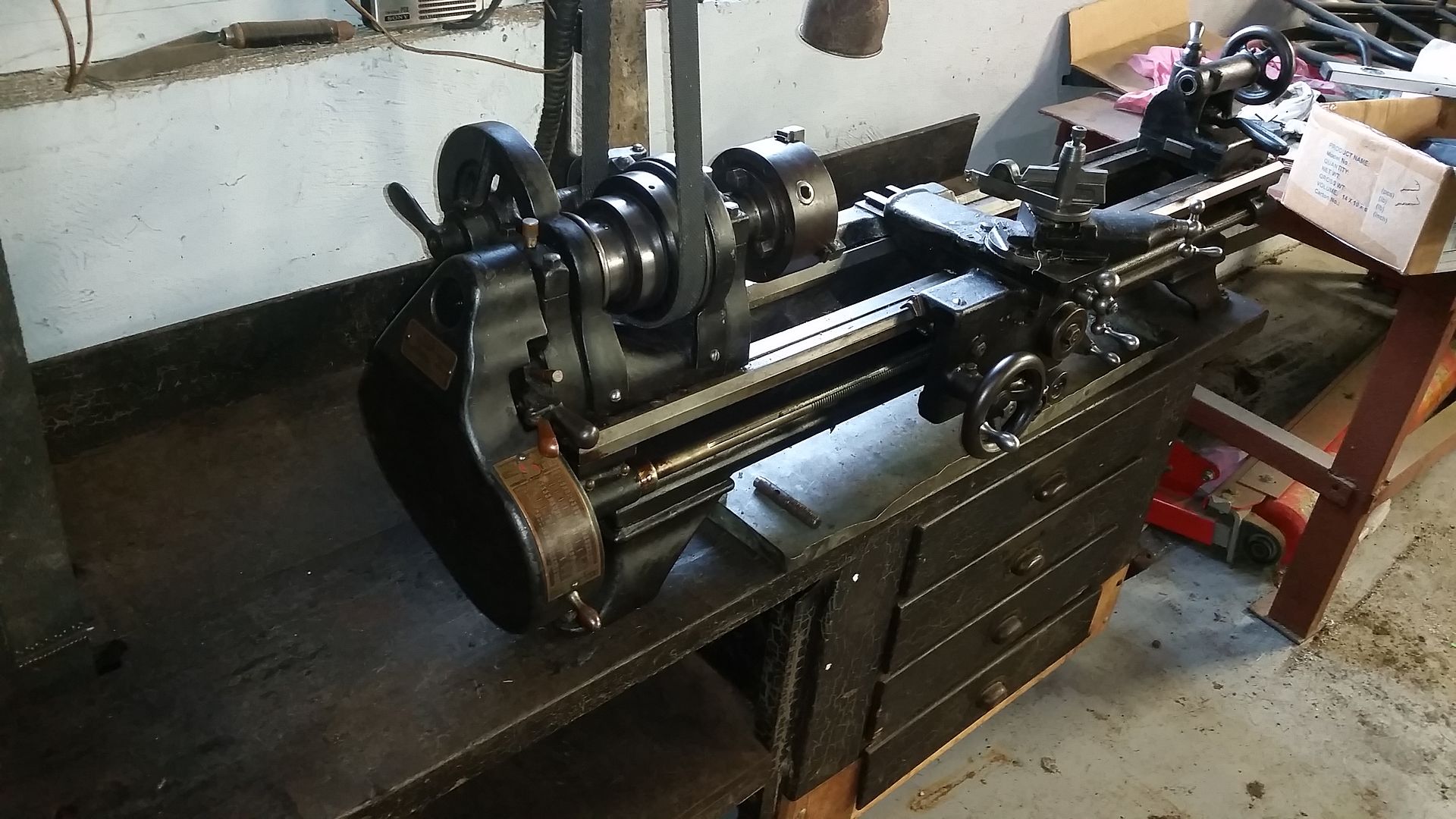

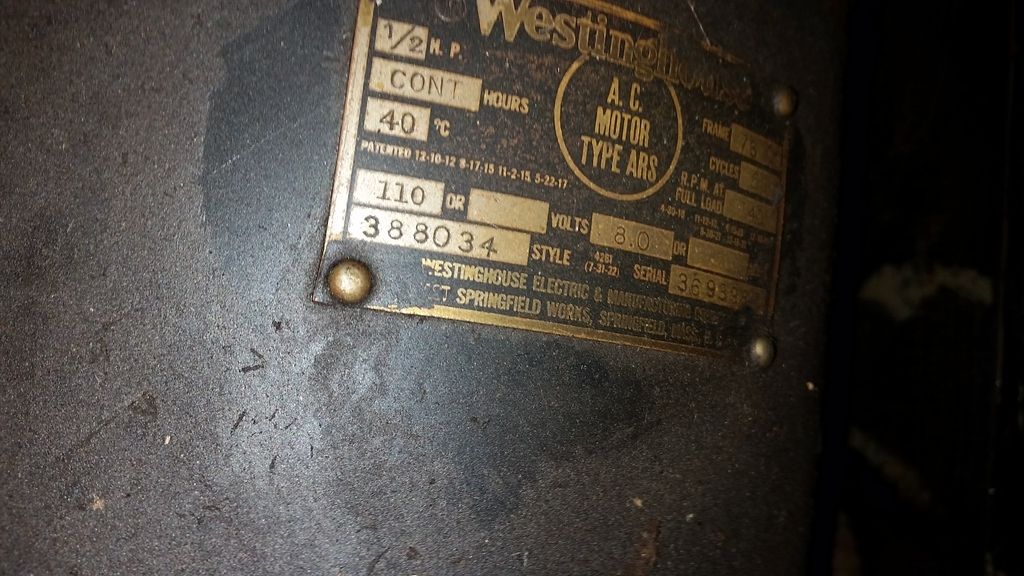

New to the forum and fairly inexperienced with lathes. Played around with one back in college and haven't touched one in a decade. I'm a mechanic at a golf course I enjoy fabricating things and have wanted one for awhile, i run into a fair amount of stuff that i could use a lathe for. Particularly the rollers on the cutting units. I picked this up for $500 over the weekend i hope it was worth it. It didn't come with a 4 jaw chuck, what is a decently priced one?