Nathanhamler

Plastic

- Joined

- Oct 7, 2015

Hey everyone, so I just picked up my first south bend, a 9a precision, everything looks good so far...I do have machining experience, just not much with this machine, and machines in general that aren't set up correctly.....and I don't think this one is set up correctly....

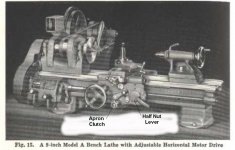

I dont think my gear train is set up properly to get the feed rates i'm supposed to be getting when I switch the tumblers....I've got it set on 8tpi/.043 and if I do a scratch threading pass on those settings, I get about 28-30 tpi....I dont have a thread gauge here with me currently, so don't kill me....also, if I put an indicator on the carriage and turn the chuck by hand, I get about .034" per rotation of the chuck....at 8tpi that should be more like .125" per rotation...currently I've got it set on direct drive, speed 2 out of 12....so i'm WAY off on what it should be feeding at....

Here Is a pic of my gear train.....sorry if this is an easy one, I could probably look all day and not find the answer, being that there are so many threads in this forum....

I dont think my gear train is set up properly to get the feed rates i'm supposed to be getting when I switch the tumblers....I've got it set on 8tpi/.043 and if I do a scratch threading pass on those settings, I get about 28-30 tpi....I dont have a thread gauge here with me currently, so don't kill me....also, if I put an indicator on the carriage and turn the chuck by hand, I get about .034" per rotation of the chuck....at 8tpi that should be more like .125" per rotation...currently I've got it set on direct drive, speed 2 out of 12....so i'm WAY off on what it should be feeding at....

Here Is a pic of my gear train.....sorry if this is an easy one, I could probably look all day and not find the answer, being that there are so many threads in this forum....