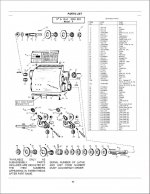

I just tried to do my first threading with my lathe . It's a 40 something 9A . I did the rebuild following directions in the Ilion book but somewhere I messed something up & my threads don't match the gear chart . I have the Army TM parts list

but it dosn't tell the teeth count on all of the gears . Can someone point me towards a Parts drawing of the gear box that has the teeth count of all the gears ? I'm sure it's something that I got crossed up on & a drawing with gear counts would

get me back in the running .

thanks

animal

but it dosn't tell the teeth count on all of the gears . Can someone point me towards a Parts drawing of the gear box that has the teeth count of all the gears ? I'm sure it's something that I got crossed up on & a drawing with gear counts would

get me back in the running .

thanks

animal