garyphansen

Titanium

- Joined

- Feb 9, 2004

- Location

- Traverse City, MI

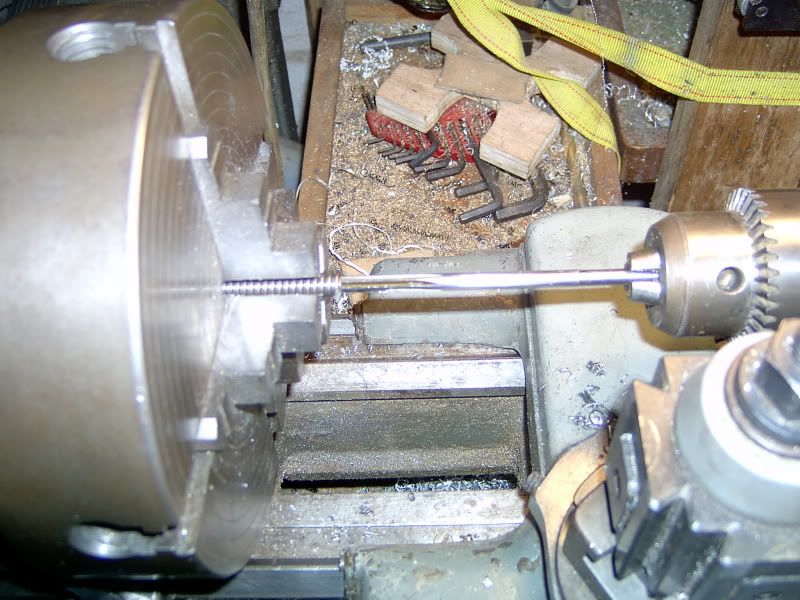

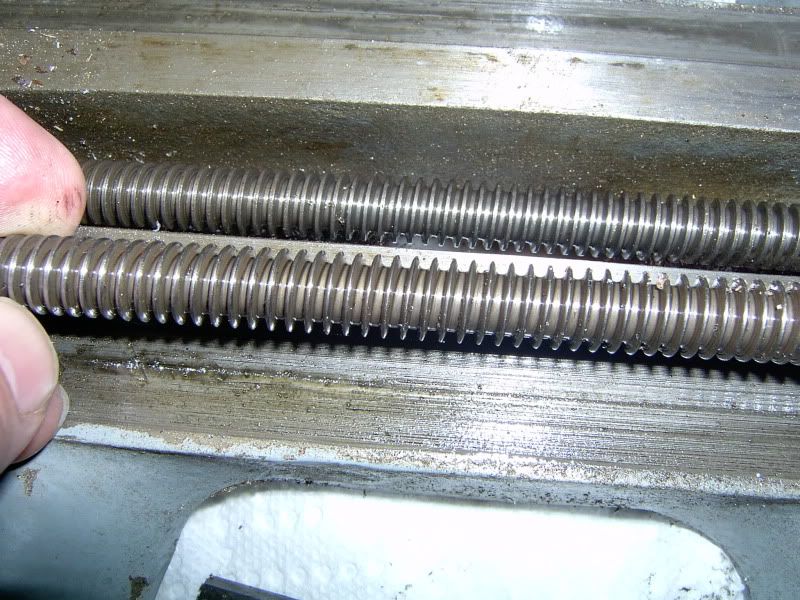

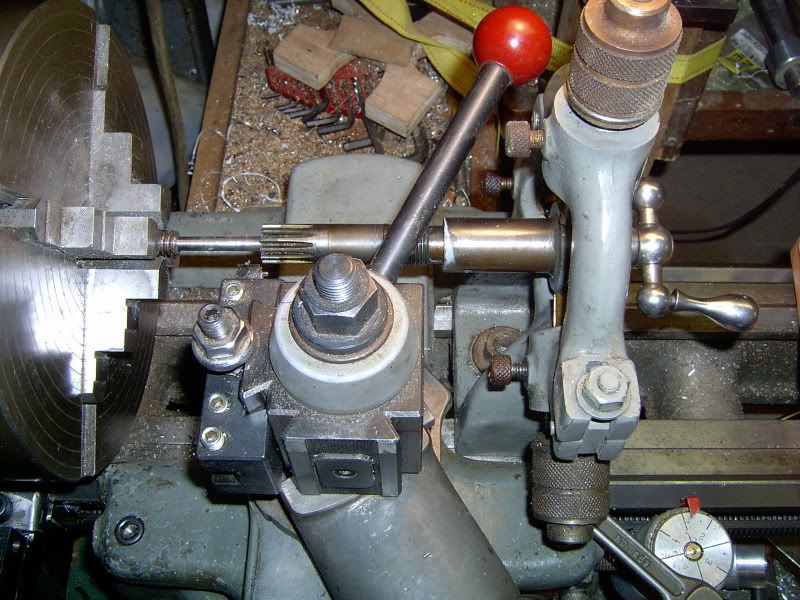

I got a new piece of LH Acme thread screw from Steve Wells a while back. I finally found a "Round to it" so I decided to fix a badly worn cross slide screw. The center of the screw was worn so bad the threads came to points. Anyway they normally cut off the screw at the gear and drill the gear and ream to .250" then turn an end of the new screw down to fit the hole. I did this one the reverse way (Because I could not find my split screw driver to take off the nut.) anyway I set up the existing cross slide screw in a four jaw chuck and adjusted it until I had .0005" runout. I set up the bushing behind the dial in my steady rest. The steady rest held the bushing stationary while the screw and handle turned. I then turned off the threads down to .250" X 1.5" long. More to come. Gary P. Hansen

Last edited: