CVRIV

Aluminum

- Joined

- Feb 19, 2021

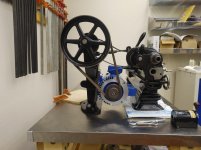

Im almost done putting this machine together.

Question#1: iIm missing the spring for the eccentric shaft used by the back gear of the headstock. What kind of spring was in there? Length, stiffness, shape, etc.

Question#2: The restoration book calls for Super Lube inside the headstock belt cone and back gear shaft. Im going to order some, but what about the nipples need to get it into these areas? What nipples do i need? Also, i noticed an oil hole on the cross slide as well. Does super lube go there as well? Do I even need nipples with a grease gun to get that grease in there? They sell plastic tubes. Can i just stick the tip in the hole and squeeze it in? So i read that oil was originally used instead of grease. I think id rather do that but what which oil to use? I used the ptfe oil/ grease to coat the back gear shaft and eccentric bearings prior to install.

Sorry i dont have pics. Ive been stupid busy.

Question#1: iIm missing the spring for the eccentric shaft used by the back gear of the headstock. What kind of spring was in there? Length, stiffness, shape, etc.

Question#2: The restoration book calls for Super Lube inside the headstock belt cone and back gear shaft. Im going to order some, but what about the nipples need to get it into these areas? What nipples do i need? Also, i noticed an oil hole on the cross slide as well. Does super lube go there as well? Do I even need nipples with a grease gun to get that grease in there? They sell plastic tubes. Can i just stick the tip in the hole and squeeze it in? So i read that oil was originally used instead of grease. I think id rather do that but what which oil to use? I used the ptfe oil/ grease to coat the back gear shaft and eccentric bearings prior to install.

Sorry i dont have pics. Ive been stupid busy.

Last edited:

ok ill use the type 7 on the back gear.

ok ill use the type 7 on the back gear.