xplodee

Hot Rolled

- Joined

- Oct 14, 2013

- Location

- Allentown, PA

Hey Guys-

The collet closer that came with my lathe is a modified hardinge hand wheel closer which does not feature thrust bearings plus the wheel is a very small diameter, this makes it almost impossible to use.

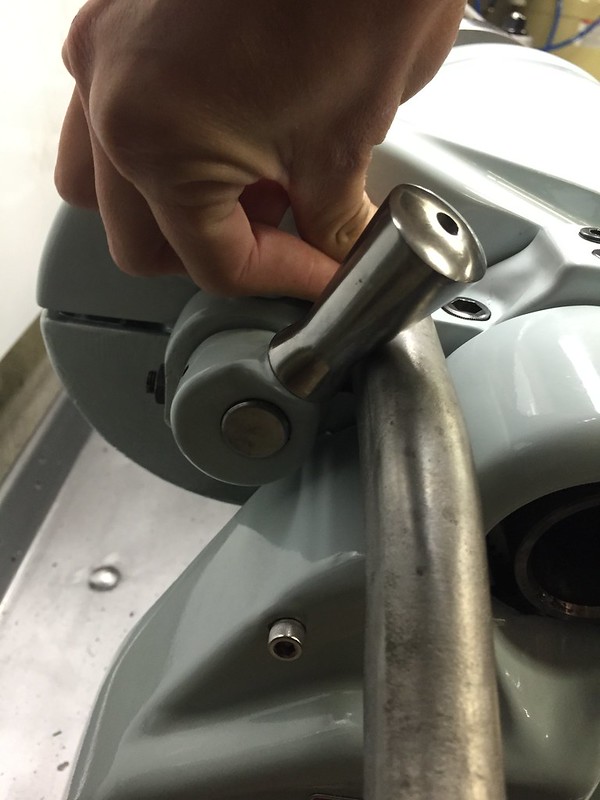

I bought a lever operated collet closer off of ebay that needed some work. I'm in process of fixing it but I had some questions:

Thank you!

The collet closer that came with my lathe is a modified hardinge hand wheel closer which does not feature thrust bearings plus the wheel is a very small diameter, this makes it almost impossible to use.

I bought a lever operated collet closer off of ebay that needed some work. I'm in process of fixing it but I had some questions:

- I have a 1943 machine, it seems like the back gear lever will interfere with the yoke lever bracket when back gear is engaged. Is this normal? Should I grind away some material from the lever bracket? Other solutions?

- Do all lever operated collet closers require a new spindle reverse gear to be fitted to the back end of the spindle? Or is this only for some versions?

- Based on how people reply to (1) and (2), I may just buy a hand operated collet closer. What do people think about using hand operated closers versus the lever operated ones? I have a lever operated unit on my HLVH so I know it's convenient, but is the hand one really that bad?

Thank you!