panabax

Aluminum

- Joined

- Mar 28, 2015

- Location

- Dallas, Texas USA

A few weeks back I won a public auction for some machine tools from a local school district. Included in the bunch was a 9A with a 4' bed. For some stupid reason, I did not take pictures of the thing in its "as purchased" state. Let's just say, it was rough.

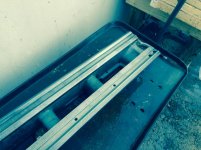

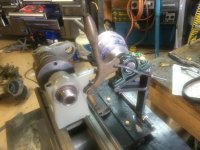

I bid on it basically because I wanted the large dial assemblies, the cast iron legs and the chip tray. I figured I could part the rest of it out and get my money back and have the stuff I wanted for free. As it turns out, it was in much better shape than I had imagined so I am in the process of cleaning it up. I have finished the bed and carriage. I think the next item on the list is to build the base for it. The legs and chip pan are Logan. The legs are awesome the chip pan, not so much. It's pretty thin and beat up. I have tried to "work on it" but I think I am going to just fab up a heavy chip pan to go with the cast iron legs.

Here are the photos from the auction.

I bid on it basically because I wanted the large dial assemblies, the cast iron legs and the chip tray. I figured I could part the rest of it out and get my money back and have the stuff I wanted for free. As it turns out, it was in much better shape than I had imagined so I am in the process of cleaning it up. I have finished the bed and carriage. I think the next item on the list is to build the base for it. The legs and chip pan are Logan. The legs are awesome the chip pan, not so much. It's pretty thin and beat up. I have tried to "work on it" but I think I am going to just fab up a heavy chip pan to go with the cast iron legs.

Here are the photos from the auction.