Greenlee52

Aluminum

- Joined

- Apr 7, 2020

- Location

- Theodore, AL, USA

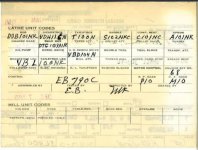

First time post from a Hobbyist. Bought a SB 13"x72" Lathe 2 years ago. I paid the $25 to find out some history on the lathe. Most of it makes sense except on the top line. It says: HARD , BED, SCREWS (LESS CONTROL). Does the less control indicate it didn't come with a on/off switch? All of the main parts that are numbered on the card are the same on the lathe. I am missing the collet tray and this lathe didn't come with a chip pan. It is a engine lathe CL 175 C, so is there a difference between the tool room version and the engine lathe version in quality or accuracy? It was sold by a company in Hammond Indiana to Calumet Steel Casting Corp. I remember seeing this company when I worked out of the Hammond Boilermaker Local back in 1995, we went by this business while looking around the area. Is anyone familiar with this company and what they made? I know it's long gone but I would like to know what this company might have used this lathe for and why no chip pan. Was the chip pan an extra cost as indicated in some of the South Bend Catalogs?

Is there a link on how to post pictures?

Please remember, I'm an nobody hobbyist learning how to machine and have fun. I hope I didn't ask any ignorant questions. From what I have been reading and learning on this forum you are all way ahead of me and I'm too old to ever be more than what I am now. I've been waiting 40 years to own a lathe. I found out after doing my first job that there are a pile of issues I am dealing with and I'm no longer able to run it but that's for another post. Thank you all for a wonder source of information.

Is there a link on how to post pictures?

Please remember, I'm an nobody hobbyist learning how to machine and have fun. I hope I didn't ask any ignorant questions. From what I have been reading and learning on this forum you are all way ahead of me and I'm too old to ever be more than what I am now. I've been waiting 40 years to own a lathe. I found out after doing my first job that there are a pile of issues I am dealing with and I'm no longer able to run it but that's for another post. Thank you all for a wonder source of information.