jeffers

Cast Iron

- Joined

- Aug 24, 2007

- Location

- Rhode Island

Hi all,

Can anyone offer any advice on how to attach an Atlas model 500/500A(?) milling attachment to a SB 10K? Is it best to attach it to the saddle for stiffness and to increase the useable height or does it go on the cross slide?

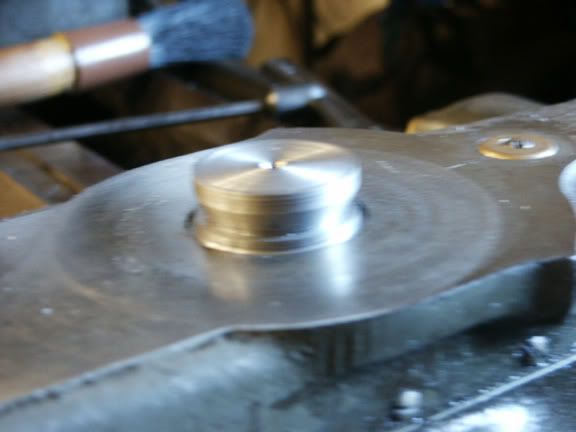

It looks as if it should tighten on to some kind of boss on the cross slide/saddle.

Has anyone got dimentions/pictures of what is required?

Cheers

Can anyone offer any advice on how to attach an Atlas model 500/500A(?) milling attachment to a SB 10K? Is it best to attach it to the saddle for stiffness and to increase the useable height or does it go on the cross slide?

It looks as if it should tighten on to some kind of boss on the cross slide/saddle.

Has anyone got dimentions/pictures of what is required?

Cheers