m_neagle

Plastic

- Joined

- Apr 9, 2015

- Location

- Lascassas Tennessee

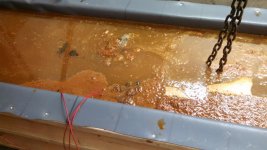

I am in process of rebuilding and painting my 13. I bought this from a school. It was the dirtiest, nastiest machine I have ever seen. I don’t think it has been cleaned since birth. Good teaching huh? I have been cleaning on it for two days. I don’t think my current method of Purple Power and engine degreaser is ever going to work.

I think it needs to soak in Purple Power or something a couple of days. I am terrified that will damage my ways or they will rust up when I remove it before I can get some oil on them. I thought about leaving the ways above the bath.

I would like to clean it up with electrolysis. That scares me even more.

Do you guys have a solution?

Also, thanks to all of you. I have learned a lot from your posts.

Michael,

Serial number 15086 T

I think it needs to soak in Purple Power or something a couple of days. I am terrified that will damage my ways or they will rust up when I remove it before I can get some oil on them. I thought about leaving the ways above the bath.

I would like to clean it up with electrolysis. That scares me even more.

Do you guys have a solution?

Also, thanks to all of you. I have learned a lot from your posts.

Michael,

Serial number 15086 T