IHateMayonnaise

Aluminum

- Joined

- Jul 17, 2016

- Location

- Albuquerque

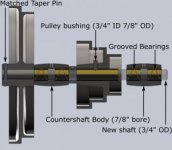

I'm bringing my 9a into operation after a very long functional restoration, and I am at a decision point with regards to the countershaft assembly that I could use some feedback on. The backstory is that the lathe came with a non-standard pulley/shaft, and I've been looking for a replacement assembly that I could purpose for my lathe. I've kept the countershaft body/base the same, but purchased a new motor (Marathon 1/2HP), and found a 60Hz original replacement step motor pulley on eBay. I purchased a separate countershaft assembly off eBay in the hopes that it would work for me, and I took out the shaft/pulley (it's a single pulley not stepped) and installed it in the original assembly. Unfortunately it appears as though the pulley/shaft has a fair amount of wobble that causes some unstability in the lathe, and so I'm finding myself looking for another solution. I was able to source a nice countershaft step pulley from eBay, but with a bent shaft. The pulley itself has a 3/4" bore, and the original shaft was 7/8" (it was stepped), and instead of simply getting a replacement 7/8" shaft and creating a shoulder and then match drilling to the pulley, I'm considering the following scheme (see attached models):

Get a precision rotary shaft from McMaster that is 3/4", and then add reducing bronze bearings to the countershaft assembly and spindle pulley. McMaster sells the "Figure 8" bearings of similar design to the spindle pulley, and as I'm tired of getting oil flung at me, I imagine it may be more advantageous to use these bearings and switch to grease.

I have two concerns with this method: 1) match drilling the shaft to match the pulley. I imagine that the only realistic way to do this is to drill both at the same time at the next size larger taper pin size. I've got a CNC mill and I should be able to do this with my machine without a problem, however I do not have any taper drills/reamers and they are exceedingly expensive from what I've found (McM sells them for $180), which is more than I was hoping to spend. 2) Securing the bronze bushing for the spindle pulley -- I can only think to do this by using the original 5/16-18 cone set screw through the bushing.. but I am not so sure how well this will work in practice. I don't want to take two steps forward and one step back, in other words.

Take a look at the models and let me know what y'all think -- see below for the McM parts in the drawing. I am hesitant to purchase a new countershaft assembly off eBay because I'm worried I'll run into the same thing I've run into in the past...

Thanks!

Cheers,

IHateMayonnaise

McMaster-Carr

McMaster-Carr

McMaster-Carr

Get a precision rotary shaft from McMaster that is 3/4", and then add reducing bronze bearings to the countershaft assembly and spindle pulley. McMaster sells the "Figure 8" bearings of similar design to the spindle pulley, and as I'm tired of getting oil flung at me, I imagine it may be more advantageous to use these bearings and switch to grease.

I have two concerns with this method: 1) match drilling the shaft to match the pulley. I imagine that the only realistic way to do this is to drill both at the same time at the next size larger taper pin size. I've got a CNC mill and I should be able to do this with my machine without a problem, however I do not have any taper drills/reamers and they are exceedingly expensive from what I've found (McM sells them for $180), which is more than I was hoping to spend. 2) Securing the bronze bushing for the spindle pulley -- I can only think to do this by using the original 5/16-18 cone set screw through the bushing.. but I am not so sure how well this will work in practice. I don't want to take two steps forward and one step back, in other words.

Take a look at the models and let me know what y'all think -- see below for the McM parts in the drawing. I am hesitant to purchase a new countershaft assembly off eBay because I'm worried I'll run into the same thing I've run into in the past...

Thanks!

Cheers,

IHateMayonnaise

McMaster-Carr

McMaster-Carr

McMaster-Carr