Hi,

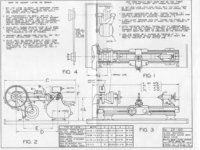

I have wired up a motor to a new to me south bend 9" metal lathe - I have belts on but haven't bolted down the motor frame yet. Is there a video or resource that someone might be able to provide guidance to a guy like me - I am super excited to learn about this tool and how to use it! Much appreciated - I can provide any details further needed -I have some original documentation - 1938! It is in tremendous shape!

Thank you,

John

I have wired up a motor to a new to me south bend 9" metal lathe - I have belts on but haven't bolted down the motor frame yet. Is there a video or resource that someone might be able to provide guidance to a guy like me - I am super excited to learn about this tool and how to use it! Much appreciated - I can provide any details further needed -I have some original documentation - 1938! It is in tremendous shape!

Thank you,

John