I bought a nice SB 9" UMD and it's on the way. Now, learning (late obviously) it won't go very fast spindle speed wise. I need the lathe to make small aluminum parts. Typically .25 to .75 inches in diameter.

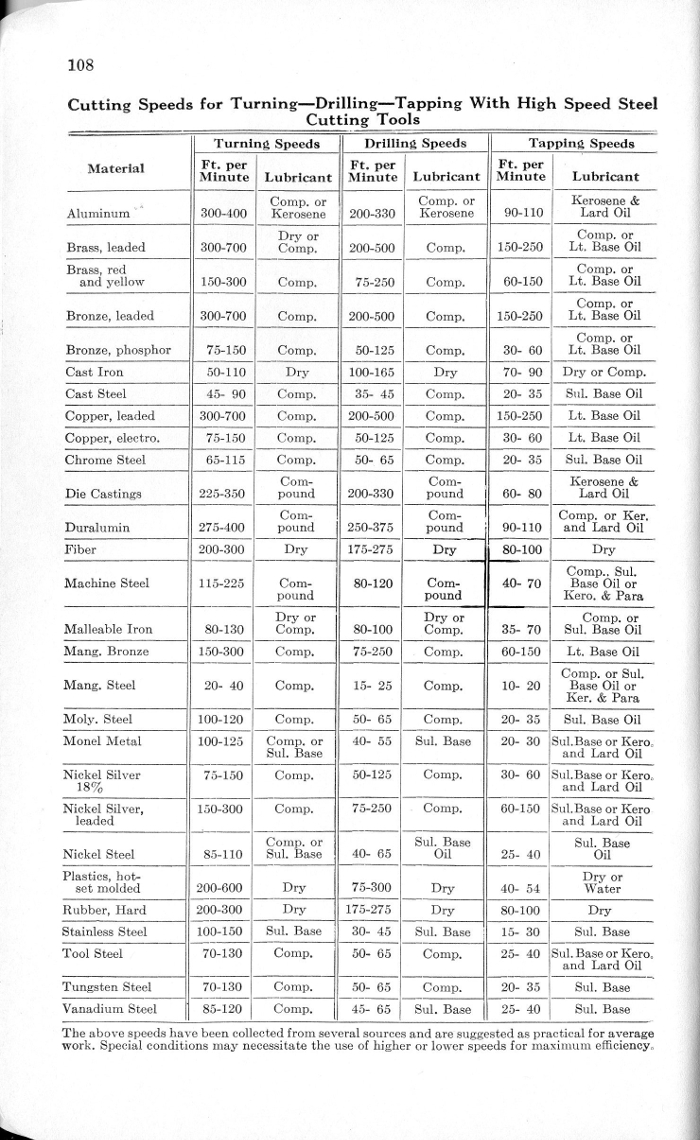

So as I understand it (now, again late) the aluminum stock I'd use should have a cutting speed of 500fpm with HSS. So on a .5" alu part I'd need 3800 RPM. The old SB catalog says my lathe's max RPM is 1365, no where near the 3800.

How bad is it going to be with the slow spindle? Sell it and go back to 7x16 @ 2000rpm brushless DC?

So as I understand it (now, again late) the aluminum stock I'd use should have a cutting speed of 500fpm with HSS. So on a .5" alu part I'd need 3800 RPM. The old SB catalog says my lathe's max RPM is 1365, no where near the 3800.

How bad is it going to be with the slow spindle? Sell it and go back to 7x16 @ 2000rpm brushless DC?

.

.