skipd1

Cast Iron

- Joined

- Jan 6, 2010

- Location

- Bismarck, ND

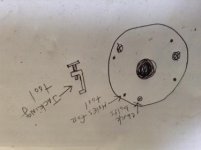

I am looking for a 6" set tru 3 jaw scroll chuck for my South Bend Model O Heavy Nine lathe. I currently have a no name chuck that has quite a bit of run out and I have a Buck 6" 6 jaw set tru that I really love. I also would like to have the jaws removable so I can make some soft jaws. I see a few nice Bucks on Ebay from time to time, but really pricey. All the Bison brand set tru chucks I've seen are completely out of my price range as a home hobbyist. I have also heard that ToolMex or TMX makes a decent set tru chuck as well. I also don't really want to go to a 5" chuck because I need all the capacity I can get. Any ideas or are there other options for Set Tru scroll chucks out there?

Thanks

skipd1

Thanks

skipd1