Golly, Gary,

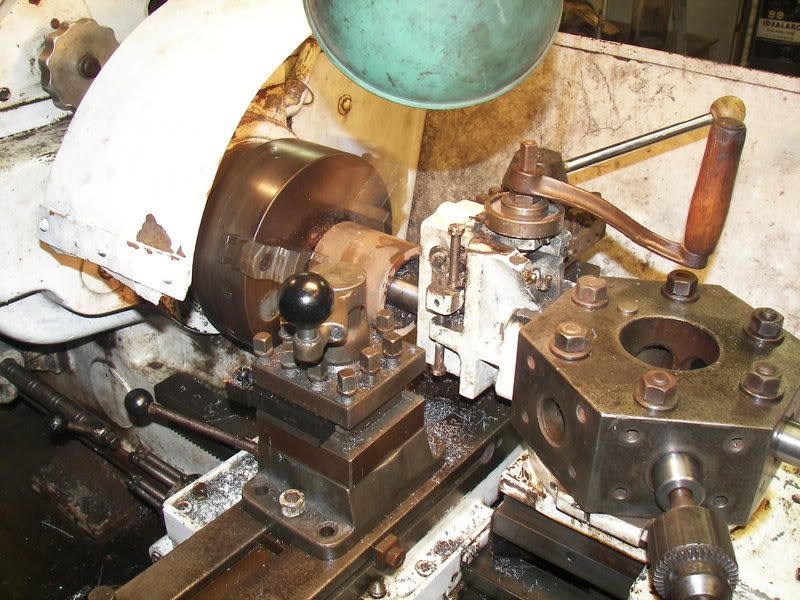

There's a ton of stuff. For the lathe:

Travel indicator holder, shoulder bolts for the carriage lock and forward/reverse gear bracket, a complete telescoping steadyrest with bronze fingers and knurled thimbles, telescoping tapping sleeve for the tailstock, two different telescoping die holders for the tailstock, a tailstock dauber or two, travel indicator holder for indicating tailstock ram travel, several chuck backplates, a spindle take-up nut, a spindle indexing fixture, a variety of spiders for the outboard end of the spindle, a thread protecting collar for the collet setup, various drill pads for the tailstock, two different milling fixtures that replace the compound, an adapter for the collet drawbar for drawing in M/Taper endmill holders in the spindle, a 15-degree raked HSS toolblock for the QC post, some larger graduated dials for the feed cranks, new Acme lead screws for the compound and the SB shaper toolhead, new bronze nut for the compound, a ball-turning attachment,and I'm sure there's other stuff I can't think of right now.

For gunsmithing:

Reamer holder, a couple of headspace gauges, a variety of barrel blocks and receiver wrenches, a bolt jewelling fixture; a variety of small parts, breeching washers, float-tube torque rings, and so on.

Specifically for the M1 rifle: reamer driver, thru-the-headstock four-jaw crowning fixture, glass-bedding clamps and tension spacers, a throat erosion gauge, receiver wrench and barrel blocks, a set-up fixture for centering the gas-cylinder lock in a 4-jaw so that the chamfer can be timed to 6 o'clock, a set of bore gauges in .0005 increments, a centering ring for unitizing the front handguard, and a set of tooling for converting the windage knob to 1/2 minute clicks, using a spring and ball detent.

Hardly a day goes by that I don't make something on either the lathe or the shaper. Not too long ago, Mrs. SB55 wrung off one of the knobs on a nearly new washing machine, and split the collar that goes over the "D" shaft, and the sheetmetal liner as well. The fix took about 15 minutes, and I'll bet I'm the only guy in the world that has a Maytag with 660 bronze collar around the selector knob shaft.

I wanted a lathe for twenty-five years, and never was in a position where I had room for one. Now that I finally got one, I'm makin' up for lost time.

Cheers,

Mike

Just like the power and feal of it but for some things the SB is far better so I'll be keeping it around.

Just like the power and feal of it but for some things the SB is far better so I'll be keeping it around.