chiniak1955

Plastic

- Joined

- Aug 20, 2008

- Location

- Oregon

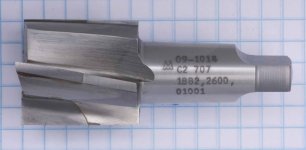

I am trying to identify the short taper on this end mill, with the hope of acquiring a holder I can use in a R8 machine. I have several and know where a lot more are.

Data: 3” OA, shank is 1.5”, ground taper is 1.125" from top of flute to bottom of tang, big end at top of flute is 0.700”, small end below tang is 0.650”

Marked: 09-1014,C2 707,1882,2600,01001 The makers mark is an outlined “M”.

Any insights?

Data: 3” OA, shank is 1.5”, ground taper is 1.125" from top of flute to bottom of tang, big end at top of flute is 0.700”, small end below tang is 0.650”

Marked: 09-1014,C2 707,1882,2600,01001 The makers mark is an outlined “M”.

Any insights?