sidecar580

Hot Rolled

- Joined

- Jan 13, 2007

- Location

- Auburn Ma

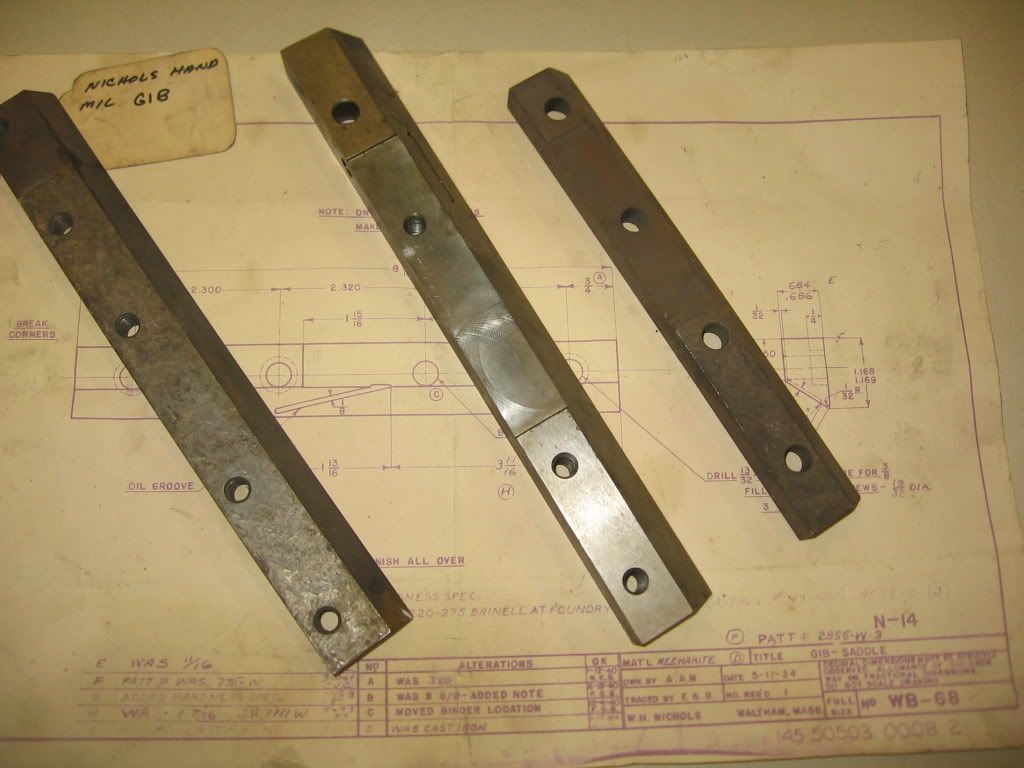

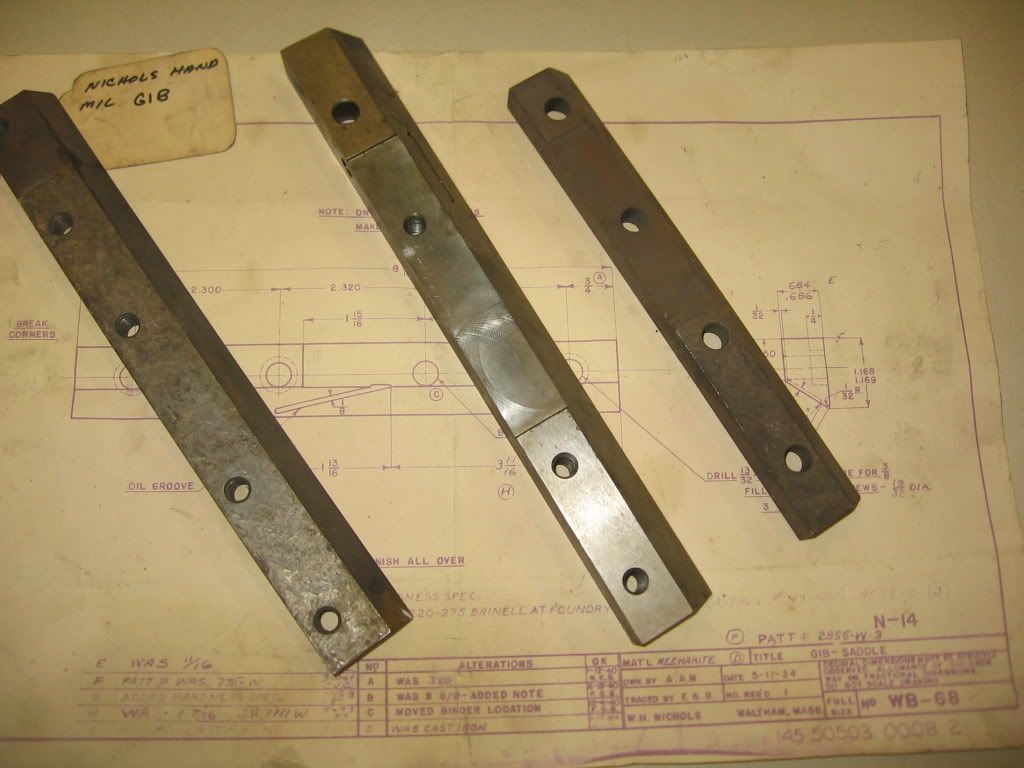

NEW gibs $100.00 each

new Nichols hand mill crossfeed nut and screws $100.00 each

new table screw $100.00

all prices plus shipping $450.00 for the lot

John Fahnestock

J&L Scraping Service

508 892-4856

www.j-lscraping.com

new Nichols hand mill crossfeed nut and screws $100.00 each

new table screw $100.00

all prices plus shipping $450.00 for the lot

John Fahnestock

J&L Scraping Service

508 892-4856

www.j-lscraping.com