claya

Cast Iron

- Joined

- Aug 6, 2006

- Location

- california

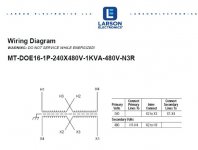

I bought a 3ph 480v I-R compressor that uses a PAIR of 1ph isolation transformers as a power conditioner. So the PC is actually setup 480v in/ 480v out. I only have 240v, 3ph power. The isolation transformers can be connected as 240v primary. With what I have, is it possible to setup the PC as 240v in / 480v out? Or am I just better off buying a 240v / 480v 3ph transformer.