Hello, I am beginner hobbyist and could use some help with little problem.

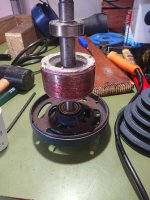

I've got a 2nd hand drill press, 250W single-phase brushless, AC 220V, 1400 rpm, sized 18cm high x Ø18. I can drill 13mm in free machining steel but on other less friendly materials it stalls easily. I've measured the 6μF capacitor at 0F, got a replacement which measures correctly, but the issue remains. I can stop the motor pulley without any effort or risk. I don't think that is normal? To what should I look now?

I've got a 2nd hand drill press, 250W single-phase brushless, AC 220V, 1400 rpm, sized 18cm high x Ø18. I can drill 13mm in free machining steel but on other less friendly materials it stalls easily. I've measured the 6μF capacitor at 0F, got a replacement which measures correctly, but the issue remains. I can stop the motor pulley without any effort or risk. I don't think that is normal? To what should I look now?