Steve in SoCal

Titanium

- Joined

- Oct 17, 2006

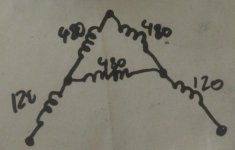

I just got a grinder(pedestal grinder) that turns out to be 550 volt machine. I was comparing the sound to another grinder I have that IS 480 volt machine. The 550 grinder has smaller wheels and spins up slower than the other grinder, it seems to run at a bit lower speed? There is a 2 leg starter/ overload that is working with a 550 coil.

The voltage here is near 490 generally.

Any issues or mitigation short of a transformer? It is not going to be used 8 hours a day, a few 5 minute bursts is about the workload expected.

Steve

The voltage here is near 490 generally.

Any issues or mitigation short of a transformer? It is not going to be used 8 hours a day, a few 5 minute bursts is about the workload expected.

Steve