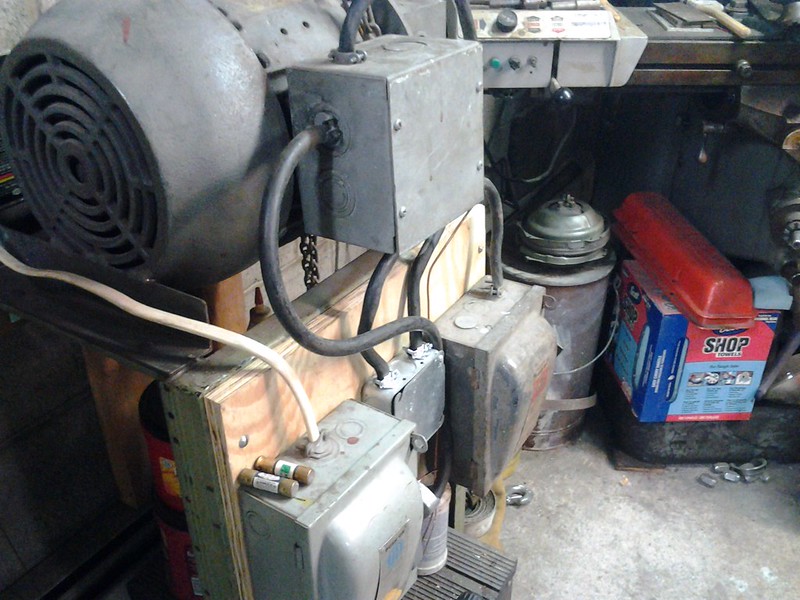

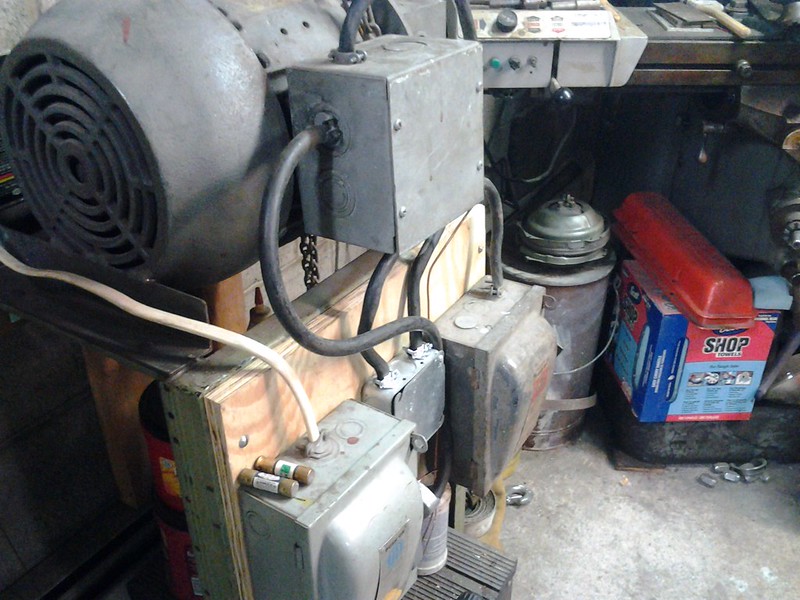

It's alive, after 3 years sitting, an old HS buddy that worked for PECO, got it up and running

20180606

20180606

[url=https://flic.kr/p/JhnpyM] 20180606

20180606

Paid $500.00 for both units

20180606

20180606[url=https://flic.kr/p/JhnpyM]

20180606

20180606Paid $500.00 for both units