Your motor plate confirms the Voltage of the motor you are using! 120VAC voltage drop is what your calculating. 120VAV is measured to neutral and there is NO neutral in 3 phase. Don't get involved with 120VAC when working with 3 phase. The calculator for 120VAC probably assumes 600' of wire 300' out and 300' back, I assume it's an online calculator. Forget any 120VAC voltage drop, concern yourself with 3 phase voltage drop. Using 120VAC voltage drop does not apply.

My 120 volt statement seems to be throwing everyone.

120 volts IS the measured voltage carried in each conductor.

The damn wire and the resultant voltage drop does not care that three conductors are combined with differing phases to be three phase at the other end in a motor to do work.

The only issue is to make sure to calculate at one way not round trip (I am doing that).

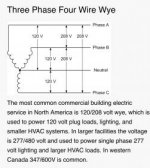

I am using this page to define the type of three phase present on site:

Electrical Service Types and Voltages – Continental Control Systems, LLC

That site states the ground as “

neutral” so I am using that convention:

This is the stated vocabulary for three phase systems with Wye having a neutral present:

I am using this site to calculate voltage drop:

Voltage Drop Calculator

I am using this site to specify wire size:

Wire Size Calculator

This whole exercise seems to make clear I was assuming some black art with designing three phase circuits.

I am well used to specifying wire size using a 3% voltage drop table.

It appears my question was that simple- state load and run, pick acceptable drop and buy wire..

The only question is I still might be not in sync with the calculator when it is asking for voltage of three phase run.

Ie: “Source voltage- 120, 240, or 480?”

I am using 120 as this is voltage carried by conductor- am I screwing this up?

So running this at 1/0 aluminum and 50 amps I get 2.24% drop taking my line voltage to 117.32

From site above:

“Line-to-line voltages in three phase systems are typically 1.732 times the phase-to-neutral voltages: sqrt{3}=1.732”

So 117.32x1.732= 203.2 volts three phase so I need to buck from there.

Assuming I am adding a three phase buck transformer I can hit nameplate voltage.

I lose some amperage in the transformers I assume.

Am I getting the basics right here?