I acquired an old GE motor that is missing its wiring diagram.

have an American Rotary PC which puts out Delta voltage.

I've read through this post: https://www.practicalmachinist.com/...s-and-vfd/9-wire-3-phase-motor-wiring-102888/

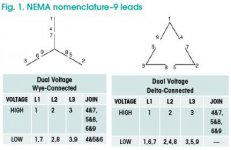

I believe my wiring should be:

L1--1,6,7

L2--2,4,8

L3--3,5,9

but I'm not sure. Don't really understand the whole Wye/Delta thing... There's the power supply, how the motor is wired, and how the motor is built... So a motor can be built and/or wired for either delta, wye, or either??

How to know w/o wiring diagram?

"Determining wye or delta connection for motors

On delta connected motor lead #s (7,8, & 9), (1& 4), (5& 2), (3& 6) have continuity with each other

On wye connected motors (1,4& 9), (3,6 & 8), (7,2 & 5) have continuity with each other."?

Thanks very much.

have an American Rotary PC which puts out Delta voltage.

I've read through this post: https://www.practicalmachinist.com/...s-and-vfd/9-wire-3-phase-motor-wiring-102888/

I believe my wiring should be:

L1--1,6,7

L2--2,4,8

L3--3,5,9

but I'm not sure. Don't really understand the whole Wye/Delta thing... There's the power supply, how the motor is wired, and how the motor is built... So a motor can be built and/or wired for either delta, wye, or either??

How to know w/o wiring diagram?

"Determining wye or delta connection for motors

On delta connected motor lead #s (7,8, & 9), (1& 4), (5& 2), (3& 6) have continuity with each other

On wye connected motors (1,4& 9), (3,6 & 8), (7,2 & 5) have continuity with each other."?

Thanks very much.