How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

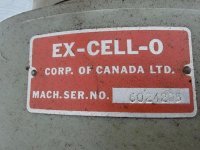

I bought an Ex-cell-o Mill (XLO) first gen mill today.

- Thread starter mark_b

- Start date

- Replies 82

- Views 6,274

ballen

Diamond

- Joined

- Sep 25, 2011

- Location

- Garbsen, Germany

I can't read your motor plate, but assume you can configure it to run off 208 or 220 or 230V three-phase. In that case you want a 1.5 HP VFD with single phase 220V input and three phase output. You should not buy a VFD that is rated a lot more than your motor, but in this case I'd suggest getting a 2HP unit. I'd also recommend a speed potentionmeter on the front panel, just for convenience in setup.

It's probably wise to avoid low-cost import VFDs and buy one from a well-known industrial manufacturer that's gotten all of the bugs ironed out. It might cost slightly more but worth it for reliability and to avoid wasted time and possible motor damage.

I've bought three TECO VFDs (these are made by Westinghouse) by mail order from Dealer's Electric:

Electric Motors | Motor Controls | VFD | AC Drive

and been very happy with them. This Teco L510 looks like it would be a good fit:

Teco L510-202-H1-N 2 HP Variable Frequency Drive at Dealers Electric

and $180 is a reasonable price.

If you want one with a removable keypad, then this would be a good choice:

Teco-Westinghouse, N3-202-CS-U, 2 HP, Variable Frequency Drive 230 Volt, 1 Phase Input, NEMA 1, at Dealers Industrial

I have one of these on my lathe with the keypad mounted up and behind the headstock, and it's worked perfectly for years.

I suggest you email them a readable copy of your motor plate and give them a phone call to double-check that one of these is suitable and that they don't have a better option. They are friendly, helpful, and competent, shipping is quick and prices/support are good.

It's probably wise to avoid low-cost import VFDs and buy one from a well-known industrial manufacturer that's gotten all of the bugs ironed out. It might cost slightly more but worth it for reliability and to avoid wasted time and possible motor damage.

I've bought three TECO VFDs (these are made by Westinghouse) by mail order from Dealer's Electric:

Electric Motors | Motor Controls | VFD | AC Drive

and been very happy with them. This Teco L510 looks like it would be a good fit:

Teco L510-202-H1-N 2 HP Variable Frequency Drive at Dealers Electric

and $180 is a reasonable price.

If you want one with a removable keypad, then this would be a good choice:

Teco-Westinghouse, N3-202-CS-U, 2 HP, Variable Frequency Drive 230 Volt, 1 Phase Input, NEMA 1, at Dealers Industrial

I have one of these on my lathe with the keypad mounted up and behind the headstock, and it's worked perfectly for years.

I suggest you email them a readable copy of your motor plate and give them a phone call to double-check that one of these is suitable and that they don't have a better option. They are friendly, helpful, and competent, shipping is quick and prices/support are good.

JackHB

Aluminum

- Joined

- May 29, 2021

I have one of these mills which I converted to CNC over 20 years ago. The transmission is more than adequate and have never seen the need to add a VFD. DRO would be the first choice and very nice if you intend to keep it manual.

Which tooling do you have ? Mine uses Universal which is hard to come by.

Which tooling do you have ? Mine uses Universal which is hard to come by.

It is three phase I have single phase power.

I don't know want tooling it takes I have CNC plasma and need to make backhoe bucket tabs with two 30mm holes consistently.

The owner passed away so they did no know anything about it. I have only watched a few videos on it.

Did you put a CNC kit on it?

I don't know want tooling it takes I have CNC plasma and need to make backhoe bucket tabs with two 30mm holes consistently.

The owner passed away so they did no know anything about it. I have only watched a few videos on it.

Did you put a CNC kit on it?

michiganbuck

Diamond

- Joined

- Jun 28, 2012

- Location

- Mt Clemens, Michigan 48035

I ran a brand spanking new XLO at Interlakes Engineering and thought it was a very good machine.

Bridgeport at the time had 6 weeks or 6 months wait for a new mill at that time.

It seems the XLO was a better price.

I would pick up a few end mill holders, they beat holding end mills in a collet.

Plus an edge finder and a good quality vise... having two same vises can be handy because you can load the other while making parts in the other.

Milling sucks in the end mill and breaks it, so one has to think about climb milling and consider using table locks often...Changing feed direction when in the part is another tricky venture you have to think about.

The simple rule with HSS cutters on steel was you need to just see the flutes, when they are a blur you are nearing too fast.

Very sharp end mills are a high asset to milling so get EMs resharpened at a small wear land, don't run them dull...A 10x loop is good to inspect your cutters.

Bridgeport at the time had 6 weeks or 6 months wait for a new mill at that time.

It seems the XLO was a better price.

I would pick up a few end mill holders, they beat holding end mills in a collet.

Plus an edge finder and a good quality vise... having two same vises can be handy because you can load the other while making parts in the other.

Milling sucks in the end mill and breaks it, so one has to think about climb milling and consider using table locks often...Changing feed direction when in the part is another tricky venture you have to think about.

The simple rule with HSS cutters on steel was you need to just see the flutes, when they are a blur you are nearing too fast.

Very sharp end mills are a high asset to milling so get EMs resharpened at a small wear land, don't run them dull...A 10x loop is good to inspect your cutters.

michiganbuck

Diamond

- Joined

- Jun 28, 2012

- Location

- Mt Clemens, Michigan 48035

A jobber drill set, a good drill chuck, reamers, and taps as you need them. Perhaps a 1/4- 3/4 and 1" end mill holder, some standard collets for holding reamers, a hold-down set with some stacking blocks/or step-up blocks. a good hand square, digital caliper, and measuring tools, edge finder, indicator and holding device, scriber and punch for layout, some keys to set in your table slots. Carefully file table slots to just remove the bugs (have a key for your gauge.), good quality file to debug table top...and then oil stone it.

Tang holders are mostly for a lathe..for a mill you want drawbar pull holders.

End mill cutters should have a flat or whistle-stop on their shank for your end mill holder setscrew to bump. often a double (one on top of the other) set screw is used for holding an end mill cutter in a holder.

Tang holders are mostly for a lathe..for a mill you want drawbar pull holders.

End mill cutters should have a flat or whistle-stop on their shank for your end mill holder setscrew to bump. often a double (one on top of the other) set screw is used for holding an end mill cutter in a holder.

A jobber drill set, a good drill chuck, reamers, and taps as you need them. Perhaps a 1/4- 3/4 and 1" end mill holder, some standard collets for holding reamers, a hold-down set with some stacking blocks/or step-up blocks. a good hand square, digital caliper, and measuring tools, edge finder, indicator and holding device, some keys to set in your table slots 9carefully file them to just remove the bugs, good quality file to debug table top...and then oil stone it.

Tang holders are mostly for a lathe..for a mill you want drawbar pull holders.

I do have a couple of these caliper and a jobber drill set

I will need to get the other things.

michiganbuck

Diamond

- Joined

- Jun 28, 2012

- Location

- Mt Clemens, Michigan 48035

I found a set of (utility) Jo blocks handy. when doing a close size I would set in the blocks on the part and hand feel to the part edge for about .002/.003 accuracy. Yes, one can also use a depth micrometer or a planer gauge for this or the caliper.

Clive603

Titanium

- Joined

- Aug 2, 2008

- Location

- Sussex, England

As the variable speed transmission is effective and reliable you only really need a VFD to do your single to three phase conversion.

Ballens suggestion of Teco units for a decent balance of cost and reliability is good but in your position I'd take a very serious look at the Eaton DE1 PowerXL range of variable speed starters.

These are a decent mid range industrial VFD configured to be as near as possible a drop in replacement for standard electro-mechanical contactor / starter units. Plain grey/white box on a DIN rail fitting with a row of screw connectors to hook it up. No display, buttons or other gubbins. Just hook up and go. Switch selection of fixed speeds or pointer knob and dial variable speed is about as sophisticated as you are intended to get.

As there is a full on VFD inside you can get a widget to adjust the innards in traditional fashion with the equally traditional help of a 250 page downloaded handbook. But that really isn't the point. (confession time I have the widget!).

Clive

Ballens suggestion of Teco units for a decent balance of cost and reliability is good but in your position I'd take a very serious look at the Eaton DE1 PowerXL range of variable speed starters.

These are a decent mid range industrial VFD configured to be as near as possible a drop in replacement for standard electro-mechanical contactor / starter units. Plain grey/white box on a DIN rail fitting with a row of screw connectors to hook it up. No display, buttons or other gubbins. Just hook up and go. Switch selection of fixed speeds or pointer knob and dial variable speed is about as sophisticated as you are intended to get.

As there is a full on VFD inside you can get a widget to adjust the innards in traditional fashion with the equally traditional help of a 250 page downloaded handbook. But that really isn't the point. (confession time I have the widget!).

Clive

As the variable speed transmission is effective and reliable you only really need a VFD to do your single to three phase conversion.

Ballens suggestion of Teco units for a decent balance of cost and reliability is good but in your position I'd take a very serious look at the Eaton DE1 PowerXL range of variable speed starters.

These are a decent mid range industrial VFD configured to be as near as possible a drop in replacement for standard electro-mechanical contactor / starter units. Plain grey/white box on a DIN rail fitting with a row of screw connectors to hook it up. No display, buttons or other gubbins. Just hook up and go. Switch selection of fixed speeds or pointer knob and dial variable speed is about as sophisticated as you are intended to get.

As there is a full on VFD inside you can get a widget to adjust the innards in traditional fashion with the equally traditional help of a 250 page downloaded handbook. But that really isn't the point. (confession time I have the widget!).

Clive

This is the one you are recommending. It does look like a nice plug and play converter. You are right all those settings are over kill.

DE1-127D0NN-N20N - Eaton - AC Variable Frequency Drive (2 HP, 7.0 Amps) - Wistex II, LLC

michiganbuck

Diamond

- Joined

- Jun 28, 2012

- Location

- Mt Clemens, Michigan 48035

For making tractor parts you might use the mill to make set-up jigs, one might have all the holes for a precision quick lay out of a part in order to drill pres the holes or just punch mark them.

Normal drills don't locate well off a mill dial handwheel or off a DRO. A center drill can locate better and a spot drill even better yet. Spotting location of all the same part height locates well bur spotting at different height is dependant on the tram of you mill, so a mill that has an adjustable tram needbe at good tram..

Normal drills don't locate well off a mill dial handwheel or off a DRO. A center drill can locate better and a spot drill even better yet. Spotting location of all the same part height locates well bur spotting at different height is dependant on the tram of you mill, so a mill that has an adjustable tram needbe at good tram..

michiganbuck

Diamond

- Joined

- Jun 28, 2012

- Location

- Mt Clemens, Michigan 48035

For making tractor parts you might use the mill to make set-up jigs, one might have all the holes for a precision quick layout of a part in order to drill press the holes or just punch mark them.

Normal drills don't locate well off a mill dial handwheel or off a DRO. A center drill can locate better and a spot drill even better yet. Spotting location of all the same part height locates well but spotting at different height is dependant on the tram of your mill, so a mill that has an adjustable tram need be at good tram..Some mills might even need a shim in the tram.

Good to test a mill for travel. At mid long-travel a mill might travel little longer than out near the ends due to wear in the lead screw, but not very much because the lead screw nut is softer than the screw so it 9the nut) wears out faster. The same with the cross travel...

Normal drills don't locate well off a mill dial handwheel or off a DRO. A center drill can locate better and a spot drill even better yet. Spotting location of all the same part height locates well but spotting at different height is dependant on the tram of your mill, so a mill that has an adjustable tram need be at good tram..Some mills might even need a shim in the tram.

Good to test a mill for travel. At mid long-travel a mill might travel little longer than out near the ends due to wear in the lead screw, but not very much because the lead screw nut is softer than the screw so it 9the nut) wears out faster. The same with the cross travel...

Clive603

Titanium

- Joined

- Aug 2, 2008

- Location

- Sussex, England

This is the one you are recommending. It does look like a nice plug and play converter. You are right all those settings are over kill.

DE1-127D0NN-N20N - Eaton - AC Variable Frequency Drive (2 HP, 7.0 Amps) - Wistex II, LLC

Yep thats the beast. The one in the picture has the setting widget plugged in. Not clear if its included in the quoted price. Excellent deal if it is. Memory says £40-£50 for the widget on top of the VFD cost in the UK when I got mine.

I needed the widget to set the high torque mis speed boost during run up to cope with occasional stalling of a compressor in barn on first start-up in sub zero temperatures. Not something you'd normally ever encounter but that was a perfect storm of hard staring due to bad compressor installation, low temperatures and an iffy supply.

Clive

I call them tomorrow make sure it is in stock.

I picked the Ex-cell-o Mill (XLO) 3 phase grinder 12” wheels and a Quincy QR 25 240 – 12 pump/motor that will need some work but turns over and it is putting out air.

The Quincy sat outside for some time but I think I can make it look nice and work good down the road.

All for $1,260 I saw it as soon as it was posted to marketplace and jumped on it.

I picked the Ex-cell-o Mill (XLO) 3 phase grinder 12” wheels and a Quincy QR 25 240 – 12 pump/motor that will need some work but turns over and it is putting out air.

The Quincy sat outside for some time but I think I can make it look nice and work good down the road.

All for $1,260 I saw it as soon as it was posted to marketplace and jumped on it.

ballen

Diamond

- Joined

- Sep 25, 2011

- Location

- Garbsen, Germany

Here is a better picture of the motor front.

OK, that's readable. You can use either of the VFDs that I suggested in my post above, or any 1.5 - 2HP VFD with a 220V single phase input and 220V 3-phase output.

Before hooking up the VFD, be sure to open the motor connection cover and make sure that the motor is jumpered for low voltage (220) and not high voltage (440).

I like the features that a VFD offers, such as:

- ramp-up slow start

- braking

- variable speed (within reason)

- good monitoring of overload

- reverse if desired

Given your background you shouldn't have any trouble reading the manual and getting this wired up. Key point to remember: the VFD output must be connected DIRECTLY to the motor, with no switching or other stuff in between.

Does your mill have a coolant pump? If so, is that also 3-phase?

PS: if everything works, you got a good deal

Rob F.

Diamond

- Joined

- Aug 5, 2012

- Location

- California, Central Coast

Congrats  Way better deal than the other guy!

Way better deal than the other guy!

Be sure to check the table lead screws for backlash. How much slop is in the hand crank in the center of the table and at the ends of the table. If it is noticably worn in the center you should set up your primary workstation to be on one end or the other, this will add wear to the non worn part of the leadscrew to even it out a little. Dont keep adding wear to the worn area in middle.

With the other 3 phase equip you just got maybe a RPC is a better choice. All the 3 phase machines run off one RPC and no need to rewire anything, RPC provides the 3 phase similar to power company, just plug in the machine (or any new machines you might add in future)

Way better deal than the other guy!

Way better deal than the other guy!Be sure to check the table lead screws for backlash. How much slop is in the hand crank in the center of the table and at the ends of the table. If it is noticably worn in the center you should set up your primary workstation to be on one end or the other, this will add wear to the non worn part of the leadscrew to even it out a little. Dont keep adding wear to the worn area in middle.

With the other 3 phase equip you just got maybe a RPC is a better choice. All the 3 phase machines run off one RPC and no need to rewire anything, RPC provides the 3 phase similar to power company, just plug in the machine (or any new machines you might add in future)

ballen

Diamond

- Joined

- Sep 25, 2011

- Location

- Garbsen, Germany

Hi Clive,

If the OP was running his mill from 3-phase power, then he could just drop one of these in to replace contacter/starter. But I think he's at home in the USA, with no 3-phase power. So he needs to rewire for single-phase (or split phase as they call 220V over there) anyway. No "drop in" solution is possible.

Cheers,

Bruce

These are a decent mid range industrial VFD configured to be as near as possible a drop in replacement for standard electro-mechanical contactor / starter units. Plain grey/white box on a DIN rail fitting with a row of screw connectors to hook it up.

If the OP was running his mill from 3-phase power, then he could just drop one of these in to replace contacter/starter. But I think he's at home in the USA, with no 3-phase power. So he needs to rewire for single-phase (or split phase as they call 220V over there) anyway. No "drop in" solution is possible.

Cheers,

Bruce

Clive603

Titanium

- Joined

- Aug 2, 2008

- Location

- Sussex, England

Hi Bruce

Being a UK guy I don't really understand the US power systems. But surely if he has 220 volts available its just the same as over here with normal 220 V single phase going to 220 V 3 phase.

The Eaton box comes in both 3 phase and single phase input versions. I've been very pleased with the single phase input ones I used and have installed.

Clive

Being a UK guy I don't really understand the US power systems. But surely if he has 220 volts available its just the same as over here with normal 220 V single phase going to 220 V 3 phase.

The Eaton box comes in both 3 phase and single phase input versions. I've been very pleased with the single phase input ones I used and have installed.

Clive

Similar threads

- Replies

- 5

- Views

- 2K

- Replies

- 27

- Views

- 2K

- Replies

- 0

- Views

- 1K