Froneck

Titanium

- Joined

- Dec 4, 2010

- Location

- McClure, PA 17059

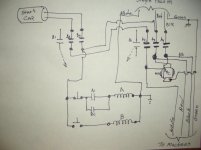

The other day my RPC started as it always did. Was running fine then the contacter dropped out while I was away form the lathe, motor was simply idling and RPC running. Thinking there was a dip in the power, I restarted but it failed to lock on, did it a few times, contacter did lock but as I walked away it dropped out. My system is simple, I have 30Amp 4 pole relay connected to a 50Amp contacter. Push button for start operates the 30Amp relay (120VAC coil) it then energizes the 50AMP that connects the RPC motor to the line as well as all other motors wired parallel to the RPC motor. All machines in the shop are connected via contacter so when RPC contacter removes power from the machine line all contacters drop out so nothing is connected at start-up except the RPC motor. Having had problem with start-up in the past and when checking found the 30Amp relay probably from China was the cause. Being I didn't use all the contacts I moved to another set. Every time I had problems with starting it was always the 30Amp relay, the 50Amp being a good Square D never gave me problems. Thinking that the 30Amp was again the problem (not thinking) I searched my stash and found a 30Amp Schneider Electric. I replaced the Chinese relay, reconnected everything and gave it a test. Worked great better than before! Before when starting I could hear the relay/relays chatter before being locked. But now all I hear is a click! The start cap is connected to the 30Amp relay so when finger is removed from start button 30Amp relay drops out disconnecting the Cap. Was happy at the time thinking I finally got rid of that Chinese relay! Later thinking at what I did, the Chinese relay couldn't have been the problem. I'll know better today after it runs for 8 hours. Anyone have any ideas? Before as I mentioned the 50Amp would not lock up, RPC started but would not stay running when start button was released. However start button was only wired to 30Amp relay, contacts on the 30Amp became the start for the 50Amp that locked itself on.