alastairseggie

Aluminum

- Joined

- Jun 26, 2013

- Location

- UK

Hi all,

I'm looking for a bit of guidance here from those in the know.

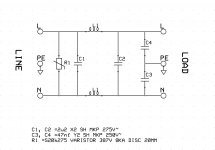

I have a single phase to three phase 3kw inverter. When I plugged it in to the mains 244VAC 50Hz (UK) the RCD tripped instantly this is before starting the drive. Connecting the motor makes no difference.

On investigation I am getting exactly half the input voltage 122VAC 50Hz between Live (or Neutral) and the Protective Earth circuit. This again does not change with motor connected or not or drive running or not.

Apart from this obvious safety issue the drive seems to perform fine!

My question to all the VSD gurus is what/where should I be looking for the issue? I know enough to know that this is likely to be in the rectification of the 244VAC but where why would it end up on the PE? Rectifier shorting to the heat sink?

Coupling Capacitor shorted to earth.... not sure why it would be coupled to earth rather than to neutral.

Basically I am stumped and don't have enough knowledge to narrow down the fault finding process.

Finally I know that RCD's give issues with inverter drives but my understanding is that this is due to harmonics or induced currents when the drive is running and to me does not seem to be my issue.

Any theory or assistance is very welcome.

Al

I'm looking for a bit of guidance here from those in the know.

I have a single phase to three phase 3kw inverter. When I plugged it in to the mains 244VAC 50Hz (UK) the RCD tripped instantly this is before starting the drive. Connecting the motor makes no difference.

On investigation I am getting exactly half the input voltage 122VAC 50Hz between Live (or Neutral) and the Protective Earth circuit. This again does not change with motor connected or not or drive running or not.

Apart from this obvious safety issue the drive seems to perform fine!

My question to all the VSD gurus is what/where should I be looking for the issue? I know enough to know that this is likely to be in the rectification of the 244VAC but where why would it end up on the PE? Rectifier shorting to the heat sink?

Coupling Capacitor shorted to earth.... not sure why it would be coupled to earth rather than to neutral.

Basically I am stumped and don't have enough knowledge to narrow down the fault finding process.

Finally I know that RCD's give issues with inverter drives but my understanding is that this is due to harmonics or induced currents when the drive is running and to me does not seem to be my issue.

Any theory or assistance is very welcome.

Al

Last edited: