Hello!

I just got done finishing the Haas Kamp conversion on 2 of my CP-200s. I got a deal on an FC-600 that I couldn't pass up. I have been working on creating a new schamatic for the conversion and was wondering if anybody could double check my work.

Here is the original schematic

Here is the new schematic after removing and adding connections

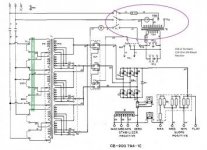

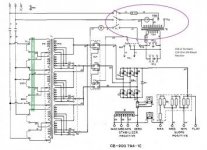

1.) I was wondering if I need to get rid of the jumper in the green box? I have looked at quite a few of Dave's guides, but he leaves it in sometimes and sometimes he takes it out. I assume that it needs to be taken out, but how do I know?

2.) In the purple oval, do I need to rewire anything over there? I don't think I should have to because it was only using two lines to begin with

3.) I was also wondering what range of capacitance I should be using. I used Haas' capacitance formula to get 300uf total (or 150uf split between banks). Should I expect the welder to operate within a range of about 120uf-180uf, or should I keep the tolerance much tighter?

Any help would be greatly appreciated. If you need pictures or anything else, Ill try to get back to you as soon as possible. I'm trying to make the pictures bigger, if I can figure it out I will change them

I just got done finishing the Haas Kamp conversion on 2 of my CP-200s. I got a deal on an FC-600 that I couldn't pass up. I have been working on creating a new schamatic for the conversion and was wondering if anybody could double check my work.

Here is the original schematic

Here is the new schematic after removing and adding connections

1.) I was wondering if I need to get rid of the jumper in the green box? I have looked at quite a few of Dave's guides, but he leaves it in sometimes and sometimes he takes it out. I assume that it needs to be taken out, but how do I know?

2.) In the purple oval, do I need to rewire anything over there? I don't think I should have to because it was only using two lines to begin with

3.) I was also wondering what range of capacitance I should be using. I used Haas' capacitance formula to get 300uf total (or 150uf split between banks). Should I expect the welder to operate within a range of about 120uf-180uf, or should I keep the tolerance much tighter?

Any help would be greatly appreciated. If you need pictures or anything else, Ill try to get back to you as soon as possible. I'm trying to make the pictures bigger, if I can figure it out I will change them

Last edited: