fredhh47

Aluminum

- Joined

- Nov 11, 2009

- Location

- Upstate New York

I have two separate problems. The first is my Kobalt 3 hp 60gal upright compressor, which seems to run fine most of the time, but it keeps eating capacitors. The one that keeps going bad (3 times in as many months) is a 161-193mfd start capacitor, the run cap seems to be OK. I am not sure why this keeps happening - any ideas? Can ambient temperature be a factor? The temp in the shop has been higher than normal, as high as 80 to 85, and the compressor is semi-enclosed to dampen noise. I have tried blowing air into the enclosure to cool the motor, but it is still going thru capacitors. The motor and compressor both turn over oK.

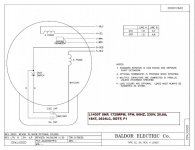

The second problem is my Worthington 100gal compressor with a Baldor 5hp single phase motor. It quit starting and would just growl and trip the breaker, even with no load, so I believed that the start caps were bad and ordered two replacements, 216-259 mfd. When I went to take out the old ones, the slip-on connectors were very difficult to remove. In the process of getting one wire off, I pulled the other end of it free from one of the other caps, either the other start cap, or the run cap. I cannot find a schematic that clearly shows how to place the wires and jumpers for TWO start caps and one run cap. No, of course, I didn't make a sketch before I went to pull the wires off. That would have been smart, right? And then I wouldn't be asking this dumb question. If anyone can make a simple sketch of how the jumpers and connections are supposed to go, I would be very happy. The 5hp motor spins over easily by hand and I can turn the compressor over also.

The second problem is my Worthington 100gal compressor with a Baldor 5hp single phase motor. It quit starting and would just growl and trip the breaker, even with no load, so I believed that the start caps were bad and ordered two replacements, 216-259 mfd. When I went to take out the old ones, the slip-on connectors were very difficult to remove. In the process of getting one wire off, I pulled the other end of it free from one of the other caps, either the other start cap, or the run cap. I cannot find a schematic that clearly shows how to place the wires and jumpers for TWO start caps and one run cap. No, of course, I didn't make a sketch before I went to pull the wires off. That would have been smart, right? And then I wouldn't be asking this dumb question. If anyone can make a simple sketch of how the jumpers and connections are supposed to go, I would be very happy. The 5hp motor spins over easily by hand and I can turn the compressor over also.