I agree the diagram posted by SAF will work. The method will reverse the run winding that will not reverse the motor but will reverse start winding connection that will reverse the motor. Though I see no indication the motor posted by the OP has a Capacitor, it seem to be a Simple split phase motor. Probably don't need the extra torque because it's a Fan/Blower motor.

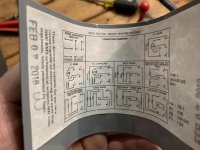

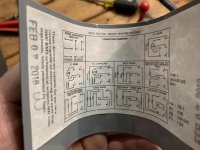

The motor connection in the photo is 240VAC and is connected as I would assume it's supposed to be in that the WHT (White) and BRN (Brown) wires are reversed and RED moved to the WHT connection allowing the start winding to operate at 120VAC. However the 240VAC connection diagram has me confused! The WHT and RED are connected as I assumed but the BRN is connected to Ground. Can anyone explain why? It makes no sense to me! Yes SAF's diagram will work for the motor in the diagram but how does it relate to the motor the OP posted?

For a explanation, I would suggest that you do a little homework for yourself. You make some assumptions, to guide the OP'er, most of which are factually incorrect. It doesn't help him by sending him down the wrong path. You could look up his motor model online, and clearly see that it is a capacitor start model, and not just a split phase. There is a internal connection diagram posted there, that shows that no internal leads are intentionally grounded.

However the factory diagram posted there, and the lead colors shown are slightly different from the model revision that he has. I had mentioned that the label shown of his motor was not clear enough to easily read, so I just posted a diagram for a very similar setup, for comparison. If he wanted or needed more specific help, it would be up to him to post a more legible data plate.

The same thing applies to the other commenters saying it should be wired for 120V to meet NEC code, and that the drum switch purchased is incorrect. Why would the manufacture list 115/208-230V operation as options, and a drum switch showing several motor types listed as suitable, including split phase and 3Φ ?

The poster upfront said that he is a green horn in connecting a drum switch and motor, does it help him any to submit incorrect information? Not intended to be critical just stating that it's unhelpful.

SAF Ω