dezil

Plastic

- Joined

- Nov 14, 2012

- Location

- Northern new Jersey

Hello everyone, I am new here and not an electrician, but I have basic knowledge. I have a south bend lathe that I swapped the table and it came with a nicer motor that what I had previously, but now i cant get it wired properly.

Here is what I know:

The motor says "craftsman" but it was made by Emerson in the 60's....Here is a photo of the plate that's on it.

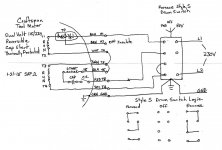

Here is a wiring diagram that I found online, it looks EXACTLY like what I have on the motor.

Here are some photo's of the switch. I know it is a furnas drum switch.

There is a capacitor on the motor that says its for 110v ( I am trying to wire it for 220v).

If you look at the photos the drum switch has 7 lugs or terminals, every diagram I have seen ( except for the one on the inside of the cover ) shows these switches with 6 lugs not 7......I cant figure out of I need to change the capacitor, some people say yes, others say it doesnt matter.

I am getting very frustrated, can someone please help me out....

Here is what I know:

The motor says "craftsman" but it was made by Emerson in the 60's....Here is a photo of the plate that's on it.

Here is a wiring diagram that I found online, it looks EXACTLY like what I have on the motor.

Here are some photo's of the switch. I know it is a furnas drum switch.

There is a capacitor on the motor that says its for 110v ( I am trying to wire it for 220v).

If you look at the photos the drum switch has 7 lugs or terminals, every diagram I have seen ( except for the one on the inside of the cover ) shows these switches with 6 lugs not 7......I cant figure out of I need to change the capacitor, some people say yes, others say it doesnt matter.

I am getting very frustrated, can someone please help me out....